SMT stands for "Surface-Mount Technology." SMT assembly involves using automated equipment to precisely place and solder electronic components onto the surface of a printed circuit board (PCB). With the advancement of intelligent technology, SMT has replaced traditional through-hole assembly. SMT technology improves manufacturing automation, significantly reducing PCB manufacturing costs and time, while also making circuit boards smaller.

SMT assembly features standardized, automated, and hole-free mounting. Combined with the use of smaller components, SMT eliminates the need for drilling compared to traditional through-hole assembly, significantly reducing costs and speeding up production.

Using short-pin or leadless electronic components, SMT effectively reduces the parasitic inductance and capacitance introduced by pins, improving the PCB's frequency and speed performance while also better controlling heat generation.

With the continuous advancement of technology, electronic products are becoming increasingly intelligent and sophisticated, placing increasing demands on PCB assembly density. SMT technology perfectly addresses this issue, making high-density PCB assembly possible.

Automated production ensures that every solder joint is properly soldered, improving the reliability and stability of electronic products.

Small components and SMT technology allow for more efficient utilization of PCB surface area.

Our company's standard process has 16 steps:

Incoming Quality Control (IQC) ensures the quality of all components and reduces material placement errors.

All materials have unique QR codes. Scan the QR code at the start of a project to obtain the correct component type and quantity, ensuring accurate placement.

PCB boards are produced according to the PCB file, ensuring the correct placement of each component pad.

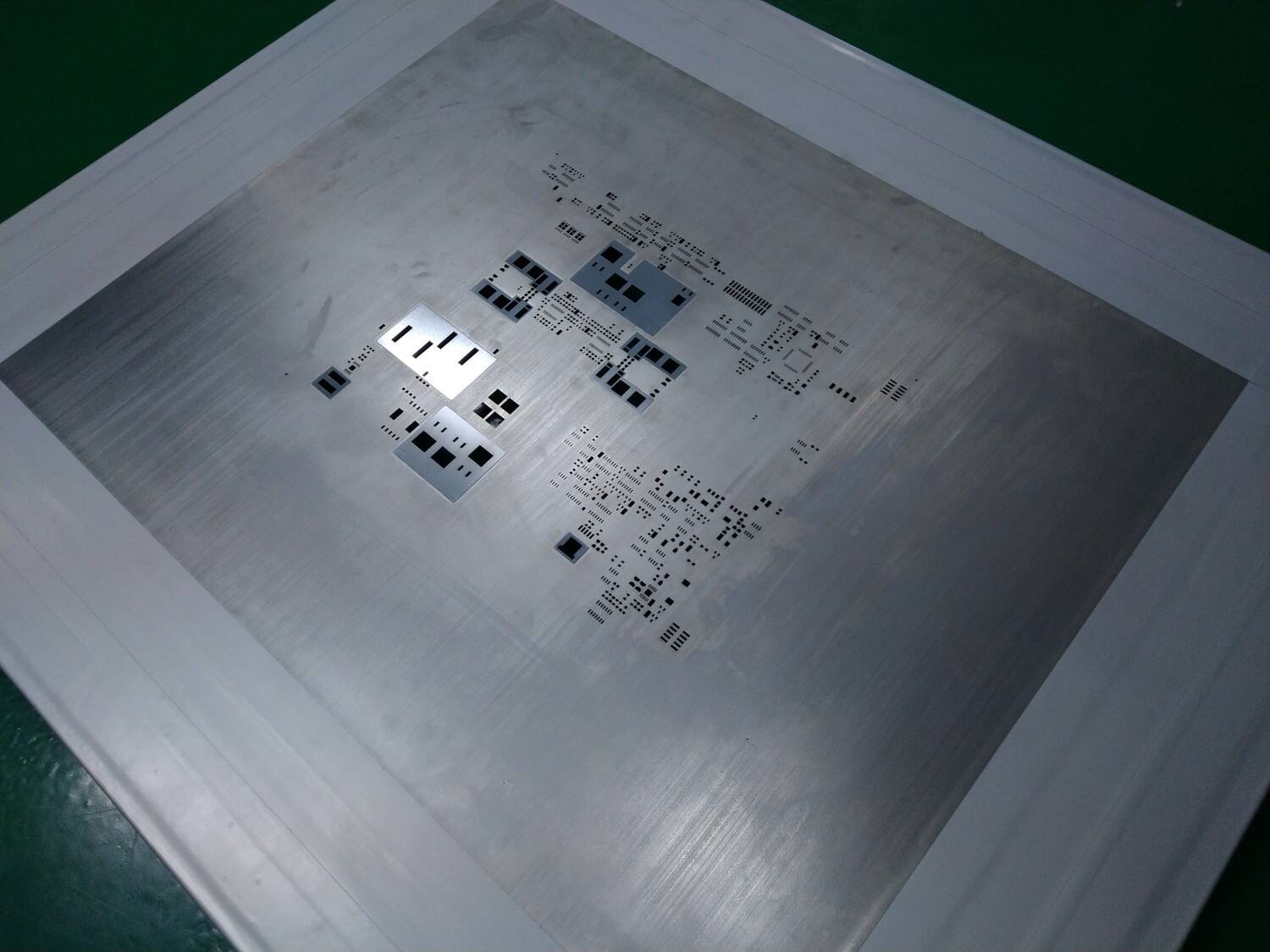

Laser-perforated stencils are produced according to the placement file for solder paste printing.

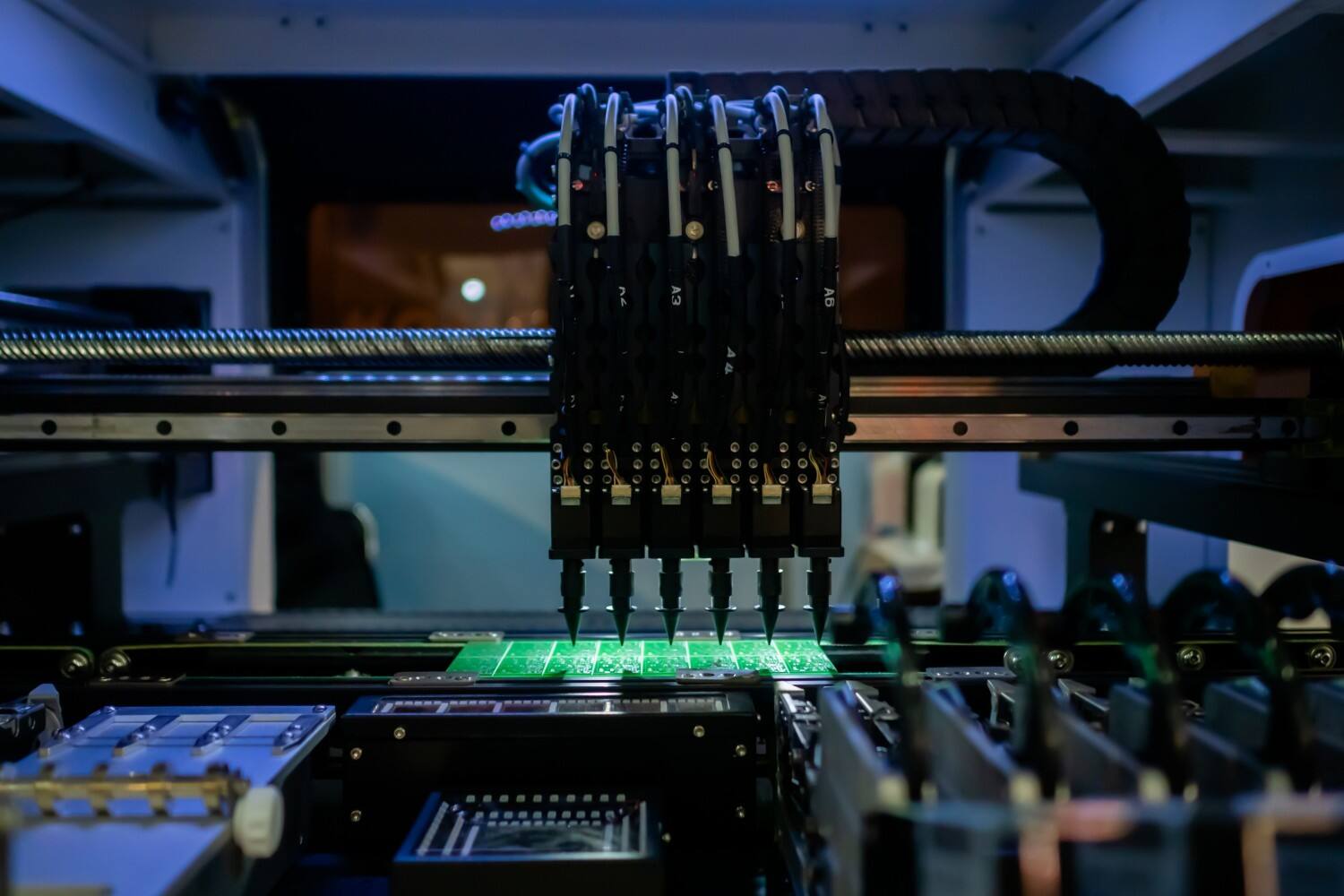

Programming the placement machine ensures accurate placement of electronic components on the PCB.

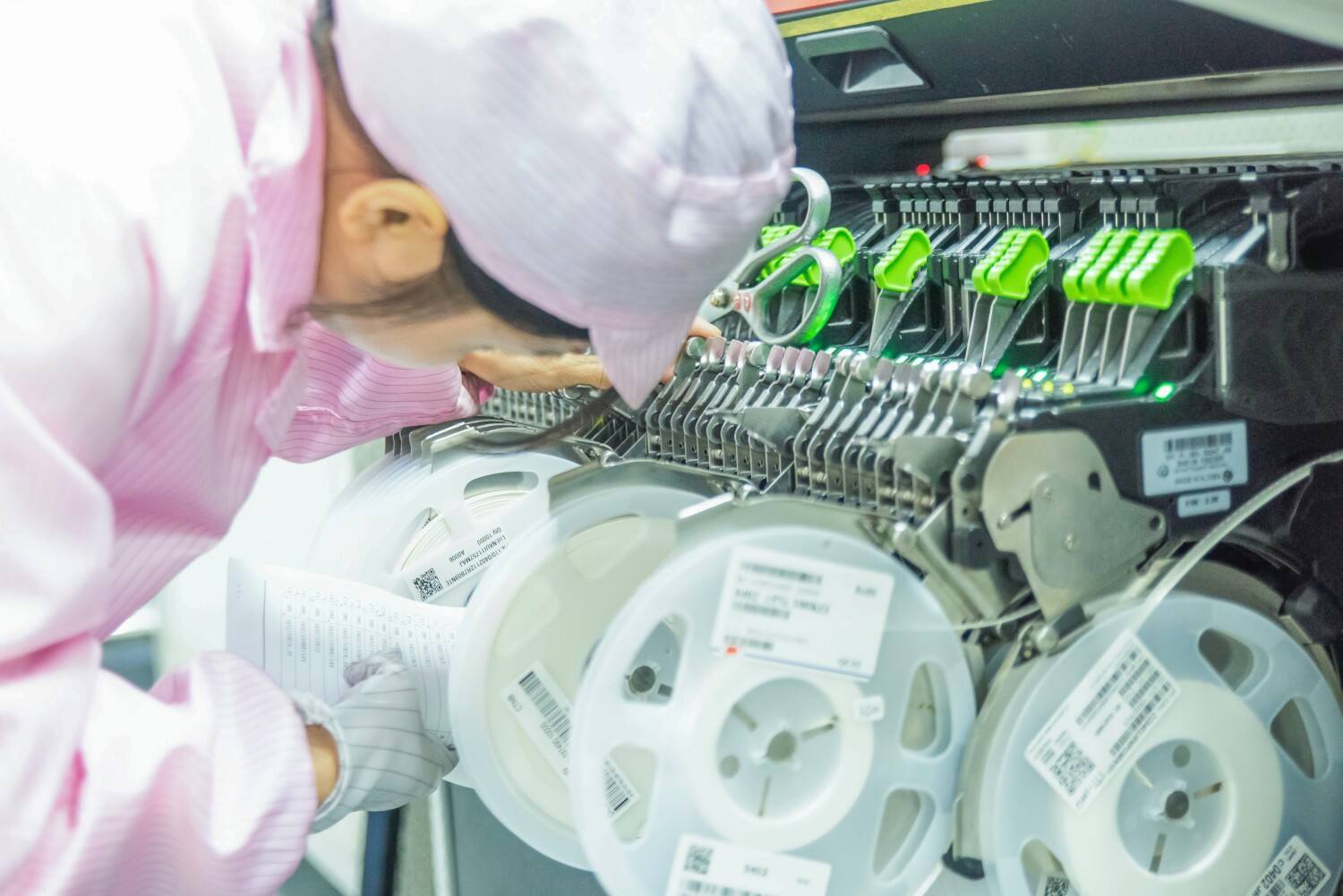

Tapes are retrieved from the warehouse and the QR code is scanned to ensure correct loading. Errors in scanning the QR code are displayed, reducing placement errors.

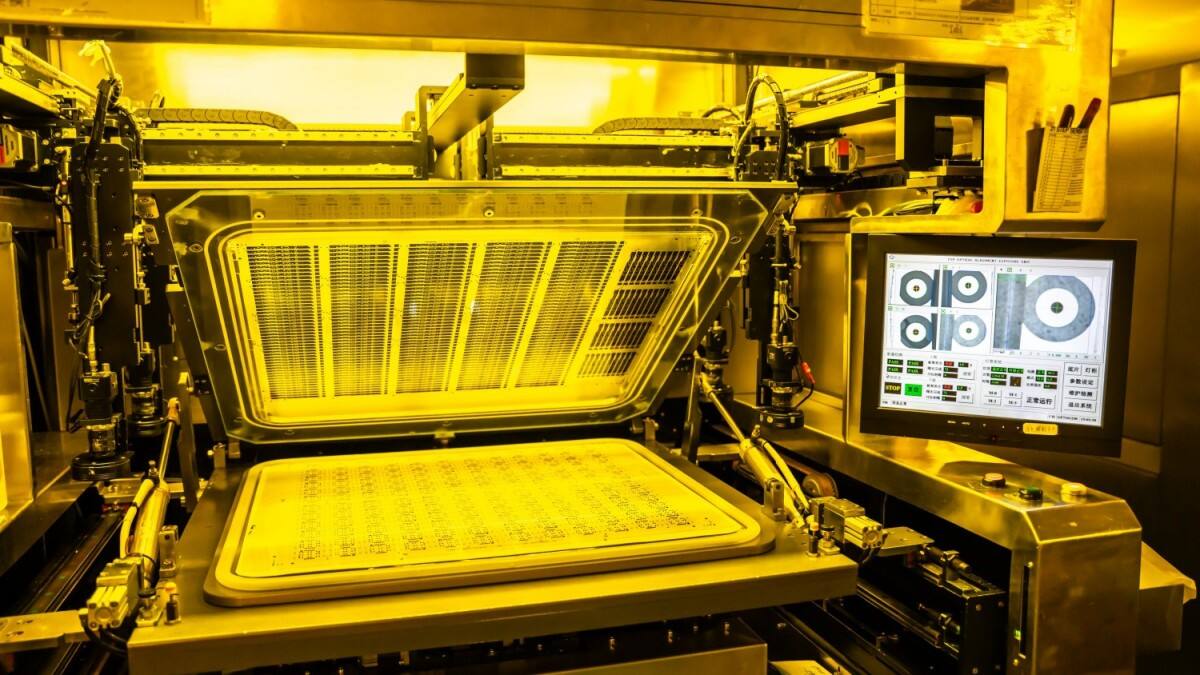

Solder paste is a mixture of flux and tin. It is applied to the PCB pads using a squeegee. Stencil thickness and squeegee pressure determine solder paste thickness, affecting subsequent soldering quality.

SPI equipment is used to inspect solder paste height, area, and flatness to ensure printing quality.

High-precision, high-speed SMT placement machines place components larger than 0201 according to program instructions, with a production capacity of over 40,000 pieces per hour.

Inspects solder paste for proper printing. If any issues are found, the process is returned for reprinting.

The reflow oven heats the solder paste to 235-255°C in 10 temperature zones, melting it and allowing it to form a connection. The solder paste then cools and solidifies. The heating gas can be air or nitrogen.

3D AOI equipment is used to inspect solder joint quality, providing greater accuracy than traditional 2D inspection and ensuring excellent soldering results.

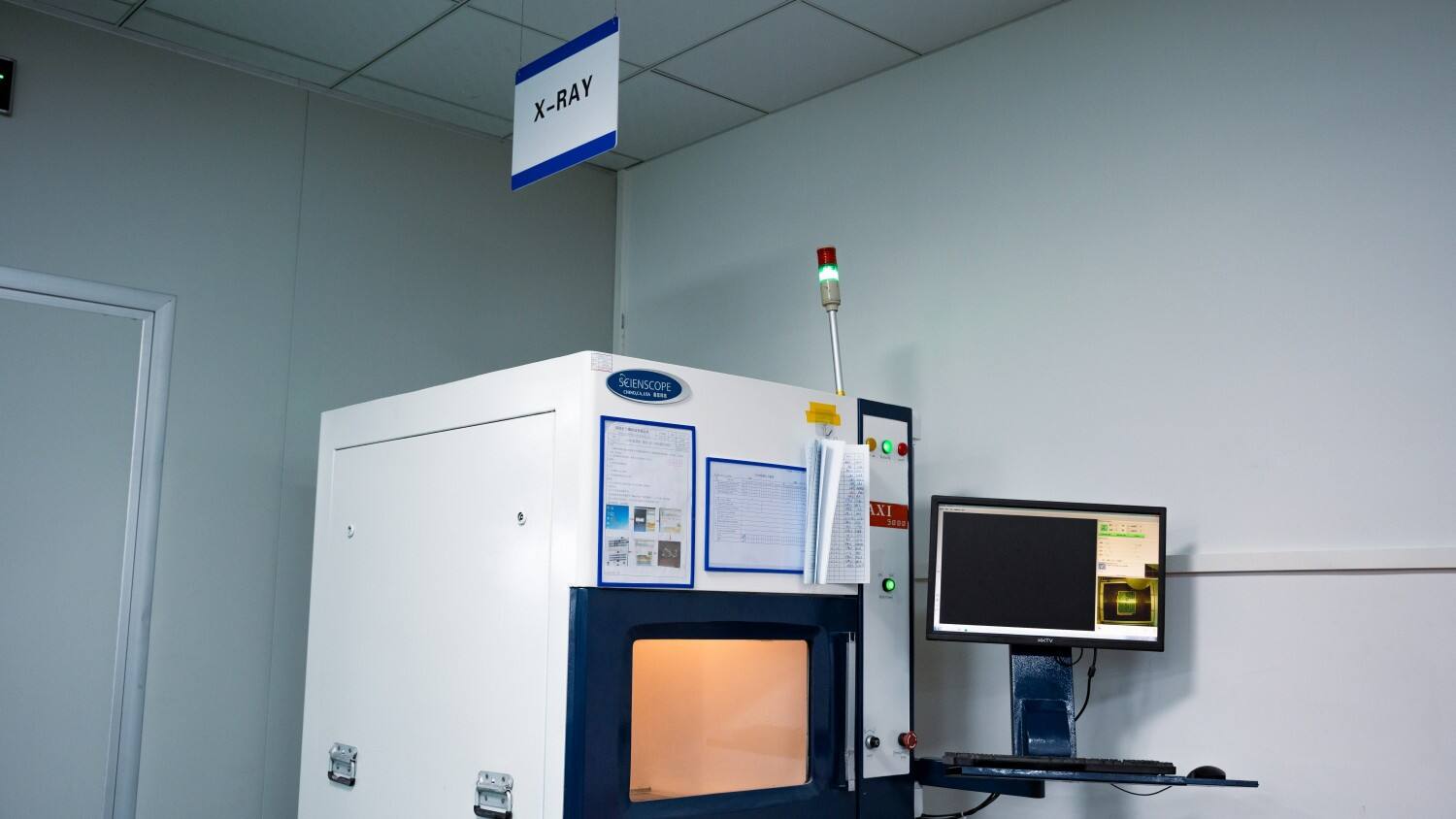

Used to inspect solder joints in invisible areas, such as BGAs. X-rays can distinguish between materials of varying densities, providing a black and white image to assess solder joint quality.

Remove surface oil and residual flux to ensure a clean board surface.

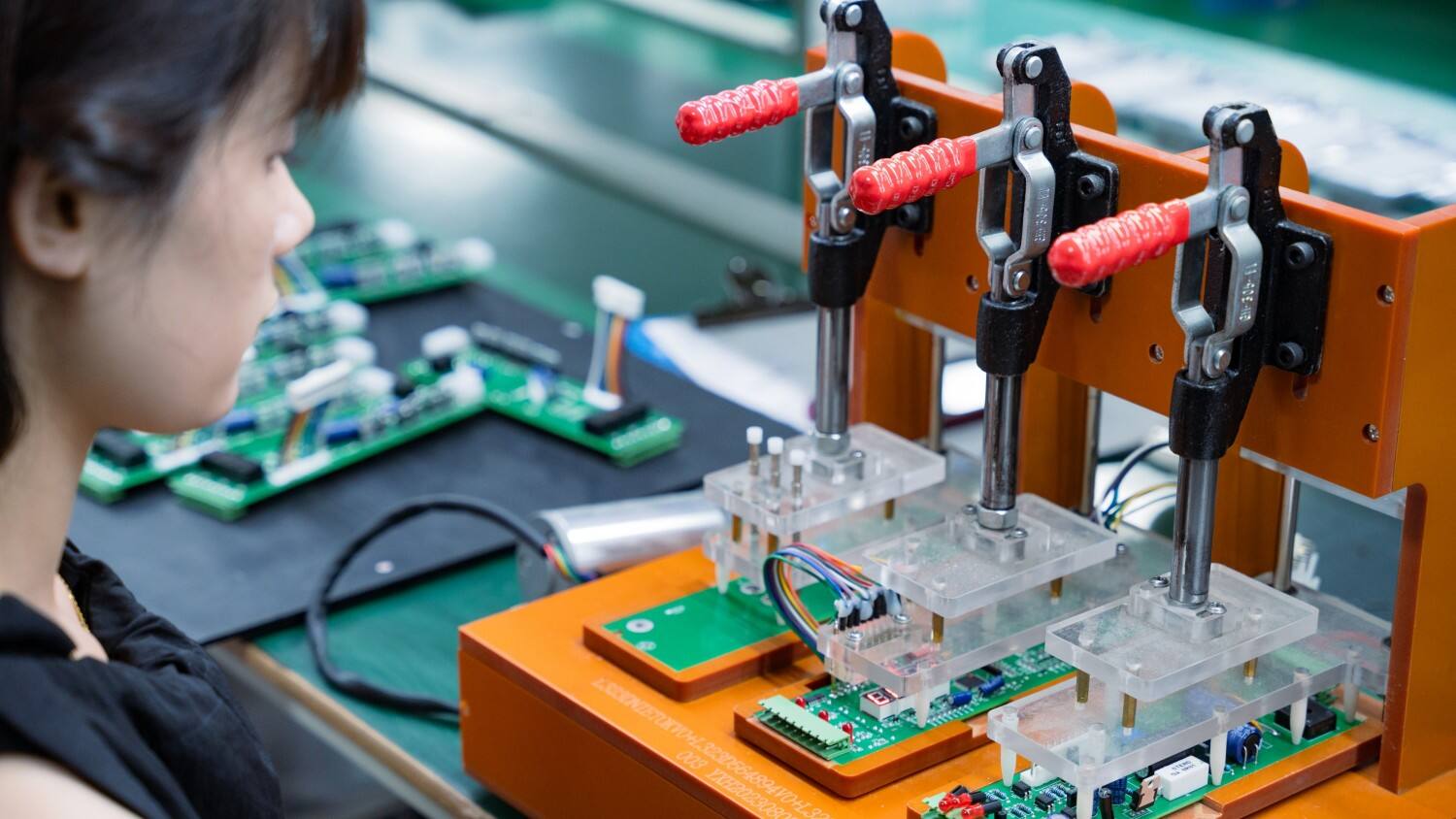

Perform final testing and inspection of boards after SMT soldering.

Static electricity can damage certain electronic components, so anti-static packaging is used to ensure safe transportation.

Solder balls form after reflow due to excessive humidity in the equipment or a dirty stencil bottom, potentially causing electrical failures.

The soldering appears successful, but in reality, the connection is not secure, resulting in poor contact and intermittent functionality.

Excessive solder connects two pads, causing a short circuit. This is usually caused by overprinting solder paste. Try reducing the stencil thickness.

One end of a component lifts up, possibly due to uneven solder paste heating or incorrect placement.

PCBally is a global high-mix, high-volume, high-speed SMT PCB assembly manufacturer with over 16 years of industry experience. PCBally operates eight advanced SMT production lines and serves customers worldwide.