What is an LED PCB?

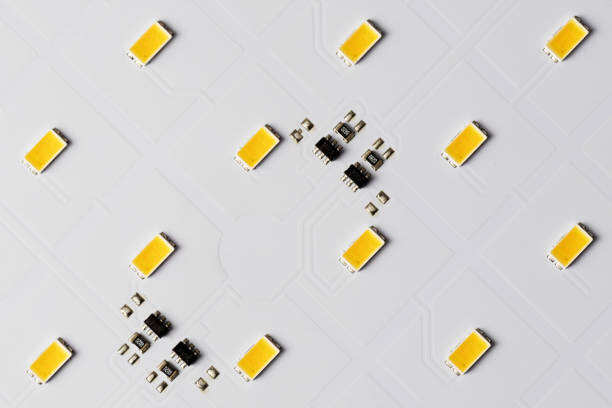

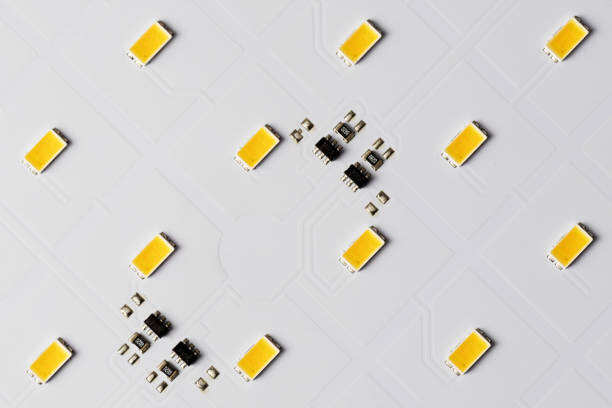

As the name suggests, an LED PCB stands for LED printed circuit board. It is primarily a printed circuit board designed for LED (light-emitting diode) lighting devices.

Before understanding LED PCBs, let's learn about LEDs. LED (Light-Emitting Diode) is a semiconductor device that emits light when current flows through it. An LED has two regions: P-type and N-type, with majority and minority carriers. When current flows through the LED, the majority carriers combine with the minority carriers at the PN junction, releasing energy in the form of photons. This is the principle of LED light emission. LED PCBs are primarily used for the installation and connection of LEDs in electronic systems such as lighting, displays, and signage. Their primary goals are efficient heat dissipation, precise electrical connections, and optimized optical performance. The performance, stability, and functionality of LED lighting and display systems all depend on LED PCBs. LED PCBs are now widely used in various lighting applications.

What fields are LED PCBs used in?

LEDs and specialized PCBs have found widespread application due to their stability and versatility:

-

Architecture:

LED PCBs are widely used in architectural lighting, such as bridges, landmarks, and other large LED lamps, which can achieve dynamic control and visual enhancement.

-

Automotive interior and exterior lighting:

LED PCBs adapt to the vehicle's vibration, temperature fluctuations, and other environmental conditions.

In-vehicle display instrument panel backlighting and central control screen backlighting rely on LED PCBs to achieve stable light output.

-

LED billboards:

In digital signage and advertising screens, LED PCBs provide bright and clear images for displaying brands, weather information, advertisements, etc.

-

Horticultural lighting:

LED PCBs are used in the cultivation of agricultural products. A large number of LED PCBs are used in greenhouse cultivation and gardening.

-

Various consumer electronics:

LED PCBs are used in screen backlights of mobile phones, tablets, and laptops, as well as indicator lights in power banks. They are widely used due to their low power consumption, high efficiency, and long lifespan.

What are the advantages of LED PCBs?

-

High efficiency: Adaptable to complex environments. Some LED PCBs feature properties such as high and low temperature resistance, vibration resistance, and corrosion resistance, making them suitable for a variety of complex environments, such as outdoor, automotive, and industrial applications, improving the reliability of lighting fixtures.

-

Long lifespan: The most outstanding feature of LED PCBs is their long lifespan, eliminating the need for frequent replacement.

-

High reliability: LED PCBs are resistant to many harsh conditions and are not easily affected by the environment.

-

Compact and convenient: These products can be installed in small devices, saving space.

-

Instant on: LED PCBs light up immediately after the circuit is connected, providing a fast response.

- Customizable: LED PCBs can be designed and manufactured to meet customer needs in terms of appearance, performance, color, functionality, and other aspects.

Disadvantages of LED PCBs

-

High Cost: LED PCBs offer excellent performance and stability, but their procurement costs can be high.

-

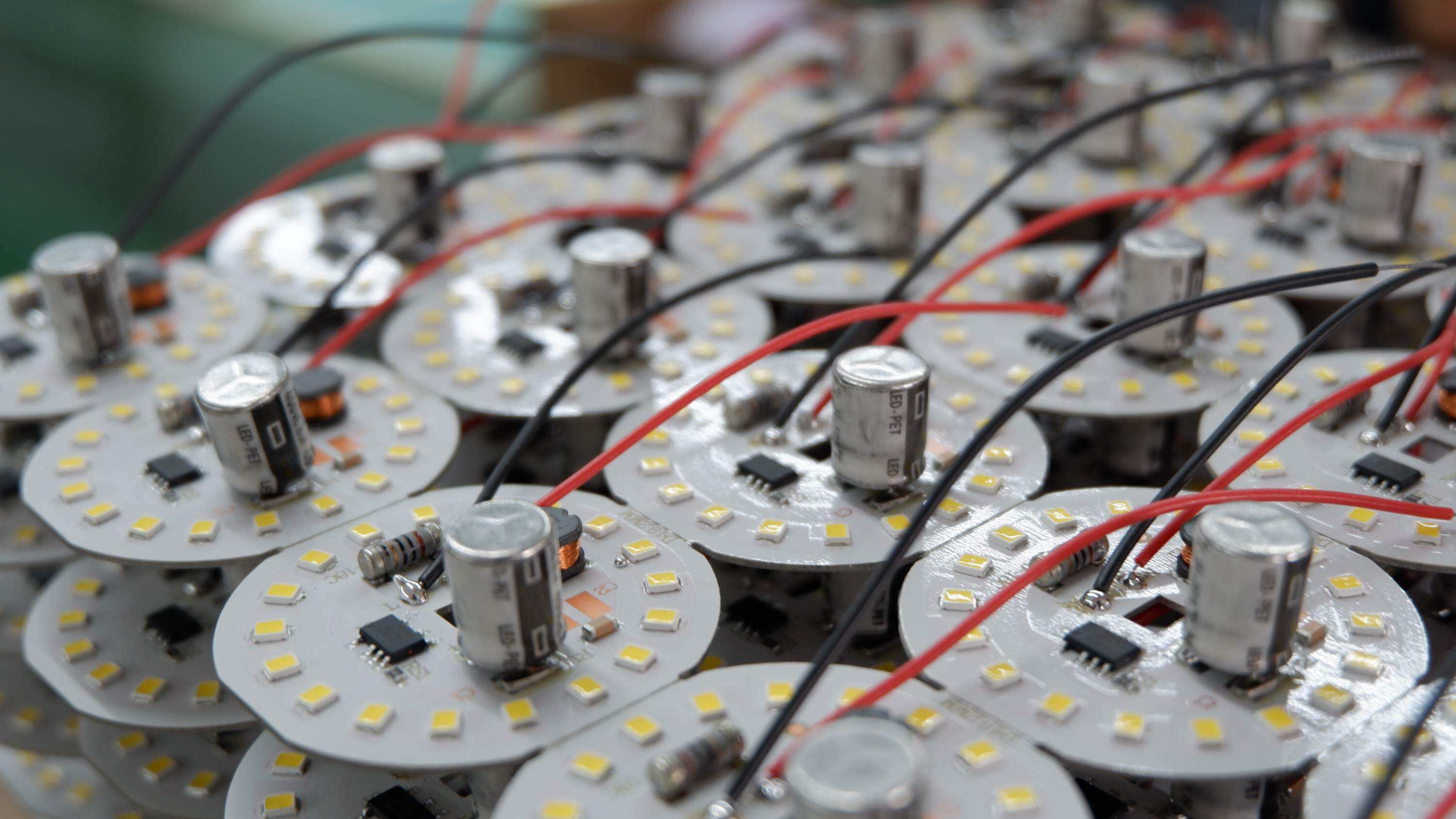

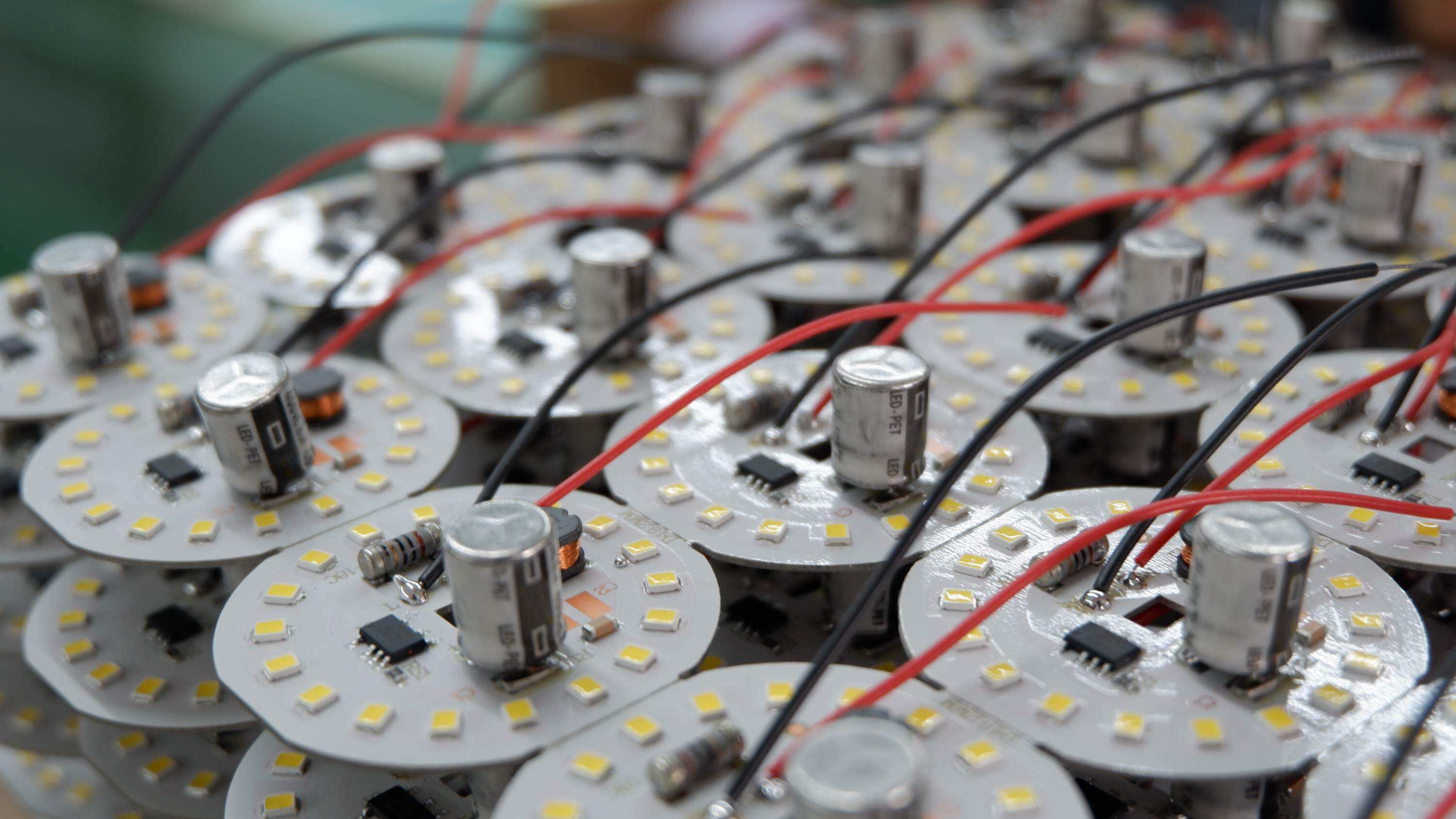

Heat Dissipation: Since light energy is converted into heat, potentially damaging thermal performance and components, a heat sink is necessary.

-

Voltage Unstable: Voltage fluctuations can cause the light to flicker or suddenly go out.

- High Manufacturing Cost: The small size and compact structure of LED PCBs increase manufacturing costs and complexity.

LED PCB Design Selection

LED PCB design generally includes the creation of schematics, key steps such as material and Gerber file preparation, and material selection. This is often accomplished using software such as CAM350:

-

Material Selection: Tongcheng prefers aluminum and copper substrates due to their excellent thermal and electrical conductivity.

-

Thermal Management: Metal-based PCBs (MCPCBs), thermally conductive substrates, thermal vias, or metal backplanes can be used to improve heat dissipation.

-

Electrical Layout: Ensure symmetrical layout and avoid long wire wraps to ensure uniform lighting and withstand the effects of light and heat.

-

Optical Design: Utilize integrated reflectors, lampshades, and lenses in appropriate mounting locations to ensure the center of the LED's light emission and minimize losses.

- LED PCB Packaging: It's crucial to choose the most appropriate packaging method for LED devices. Commonly used methods include surface mount and PTH packaging. Choose the one that works best for you.

LED PCB Specification at PCBally

Feature |

Capability |

| Substrate Material(16px) |

5052, 6061, 7075, thickness 1.6mm~9mm |

| Copper Thickness |

1oz~12oz (35μm~420μm) |

| Insulation Layer Thickness |

0.1mm~0.2mm (Bergquist Thermal-Clad, Larid Tlam) |

| Number of Layers |

1-8 layers |

| Minimum Line Width |

4mil~5mil(0.1mm~0.127mm) |

| Minimum Line Distance |

4mil~5mil(0.1mm~0.127mm) |

| Minimum Aperture |

0.3mm~1.0mm |

| Maximum Panel Size |

600mm×1170mm |

| Thermal Conductivity |

1.0~12.0 W/m·K |

| Surface Treatment |

HASL, OSP, ENIG |

| Solder Mask Spacing |

≥ 3mil (0.075mm) |

| Solder Mask Color |

White, Green, Black |

| Silkscreen Sides |

As per the file |

| Screen Printing Layer Spacing |

≥0.15mm |

| Finished Product Packaging |

Foam/Bubble Pad |

What are the advantages of Shen Zhen PCBally as an LED PCB supplier?

Shen Zhen PCBally is the steadfast choice of many customers. The details are as follows:

High Product Quality

As a high-quality supplier, we strictly adhere to international environmental protection requirements and maintain a comprehensive supply chain system, rigorously monitoring every production process, and providing impeccable after-sales service.

Perfect Delivery

Once we confirm the order for your product, we will produce it as quickly as possible and deliver it to you as quickly as possible, ensuring you never have to wait.

No Minimum Order Quantity

Our products meet international production standards and hold multiple testing and certifications. We can meet any minimum order quantity to meet your diverse needs.

Excellent Customer Service

Our company has experienced, dedicated engineers and customer service staff available 24/7 to assist you with any technical or design questions.