A PCB's bill of materials (BOM) contains a variety of components, broadly categorized as active and passive. The BOM is a master list containing all component information, including part number, supplier, quantity, and unit. Sometimes, detailed BOMs also include information on replacement components and lifecycle status.

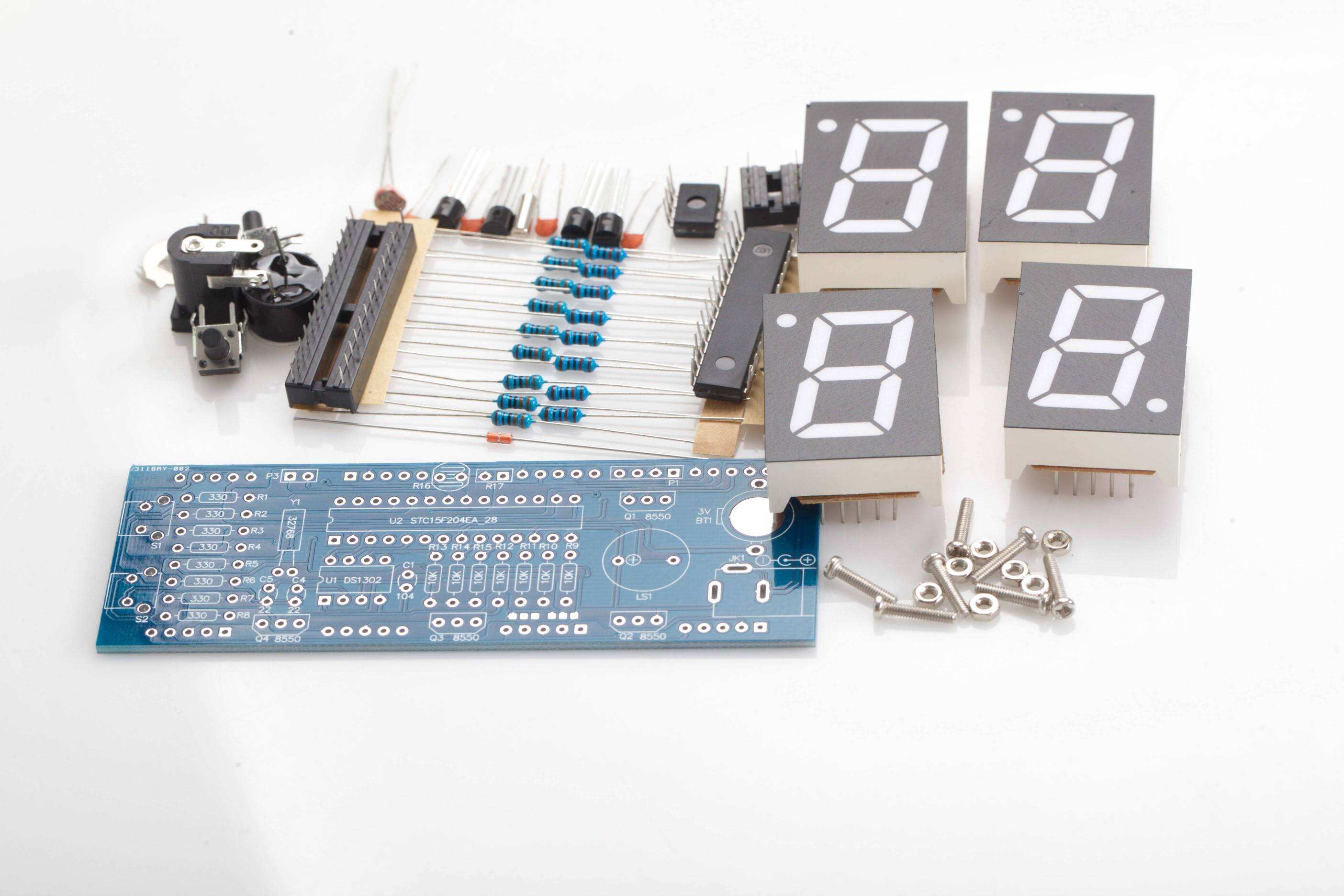

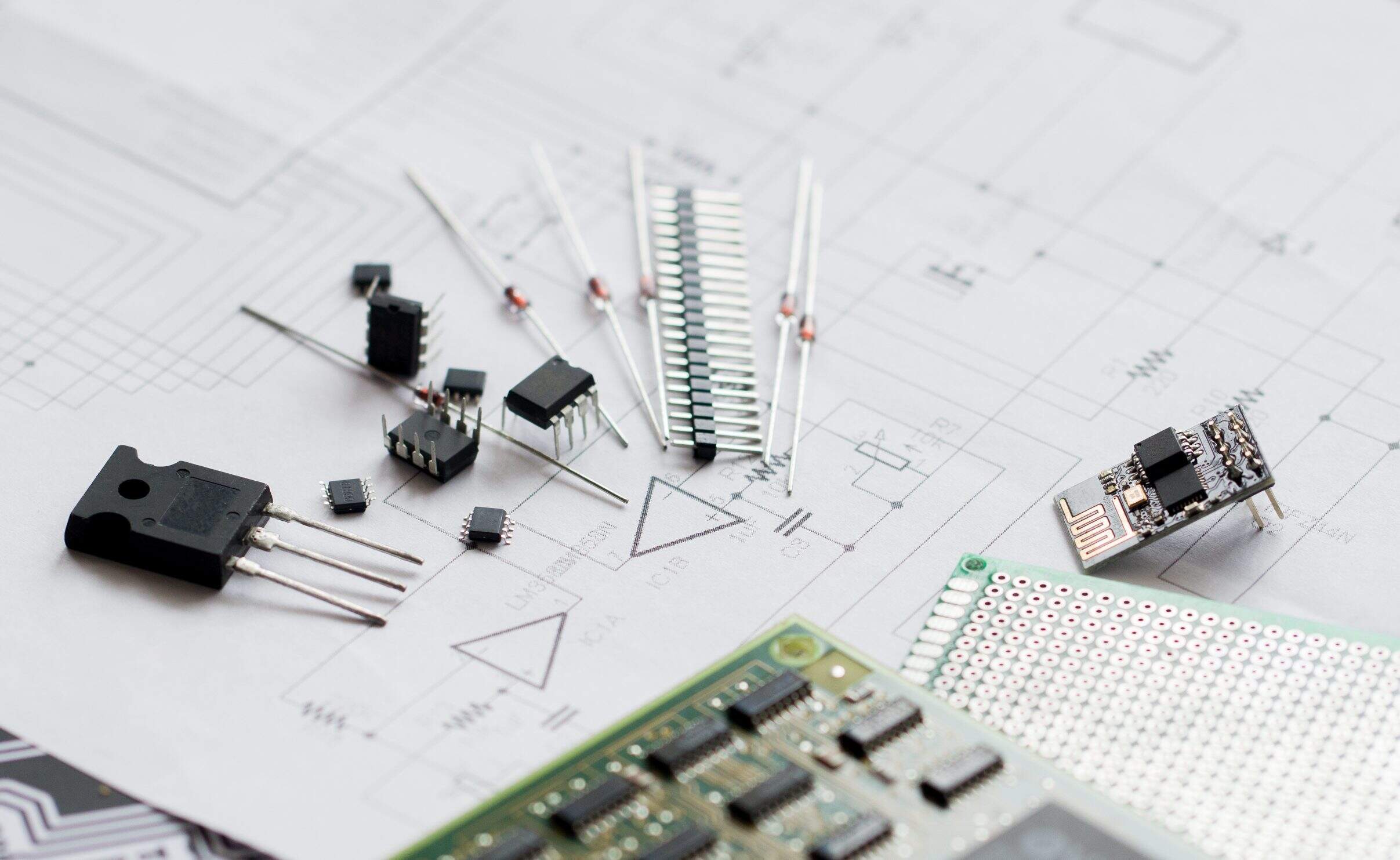

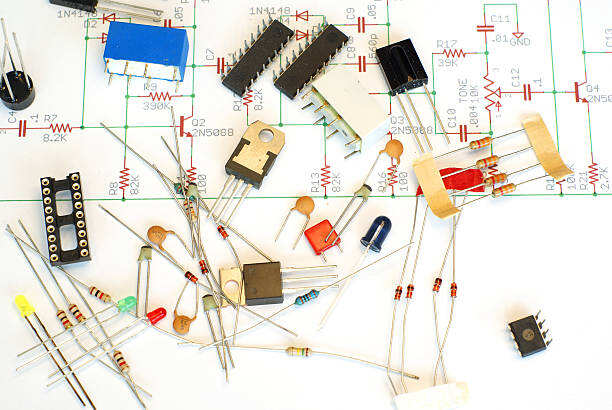

Active components are those that generate gain in a circuit's input signal. These components require an external power source to amplify or modulate the input signal. Integrated circuits (ICs) are a common active component found in PCBs. They are tiny packages that integrate multiple components, such as resistors, capacitors, and transistors, onto a single chip.

Passive components do not contribute to circuit gain and do not require an external power source to perform their functions, such as energy storage, current limiting, or voltage regulation. Passive components are often categorized by their size; for example, ""0603"" refers to a component measuring 0.06"" x 0.03"". Common passive components include inductors, resistors, and capacitors.

Common components on PCBs include integrated circuits (ICs), resistors, capacitors, oscillators, relays, transistors, connectors, and transformers. The following is an introduction to some basic components and their functions.

The purchase of PCB components should be carefully considered. The following factors need to be considered when purchasing electronic components:

When building a component list, consider alternative parts in case the primary part is in short supply or discontinued. This is an effective procurement strategy, especially critical for active components. However, be aware that alternative parts may have subtle differences in size or performance, so careful evaluation is required.

Component availability and pricing can fluctuate. Monitor the BOM status to identify any components facing discontinuation or price increases, allowing for re-evaluation and updating of the BOM.

Maintaining good relationships with reliable suppliers is crucial to the success of PCB projects. It's recommended to establish a set of supplier evaluation criteria, such as quality control systems, years of experience, company size, technical capabilities, and continuous improvement programs. You can also arrange on-site visits to gain a deeper understanding of the supplier's performance.

Establishing long-term partnerships with suppliers who can help ensure supply chain continuity and optimize procurement processes is also crucial. When selecting partners, consider factors such as location, responsiveness, and risk tolerance. The criteria for selecting qualified suppliers will be further explained later in this article.

Component procurement is crucial in the PCB manufacturing and assembly process. Even with advanced production equipment and perfect manufacturing processes, if there are problems with component procurement, it will affect the delivery and performance of the entire product. The following are common procurement challenges:

Electronic technology is constantly evolving. Component procurement teams must keep pace with technological trends and stay abreast of new materials, products, and manufacturing techniques to address the challenges posed by price fluctuations in electronic components.

PCB components are also affected by supply and demand factors such as geopolitical factors, fluctuating market demand, and price increases. Procurement teams must closely monitor market trends and proactively mitigate risks.

PCB components must comply with environmental regulations, such as RoHS and other Restriction of Hazardous Substances certifications. Additional testing and material restrictions can increase procurement complexity and costs. Therefore, it is recommended to consider environmental compliance issues early in the PCB design process.

The components required for a PCB board often depend on its design complexity. Some components are not readily available and must be customized to fit the board's size and structure. This can increase procurement challenges. Procurement teams must work closely with PCB designers to ensure that the selected components have a stable supply chain and meet technical specifications, and to provide customers with reasonable electronic component quotes.

Choosing a reliable PCB component supplier is one of the key decisions for the success of your PCB project. The following are our core advantages in component supply:

We manufacture to international standards, ensuring that components comply with environmental regulations and product standards such as RoHS. We consistently prioritize product reliability testing to ensure that PCBs are fault-free in real-world applications.

We offer attractive pricing for PCB components, ensuring satisfactory quotes without sacrificing quality. We will not compromise quality or simplify critical processes to lower prices.

With over 20 years of experience in PCB component supply, we possess extensive expertise and technical capabilities, particularly in active components and integrated circuits, enabling us to consistently meet our customers' stringent requirements for size and functionality.

Delivery time is crucial for electronic components. Our sophisticated delivery management system ensures timely delivery of components to meet the rapidly evolving demands of the electronics industry.