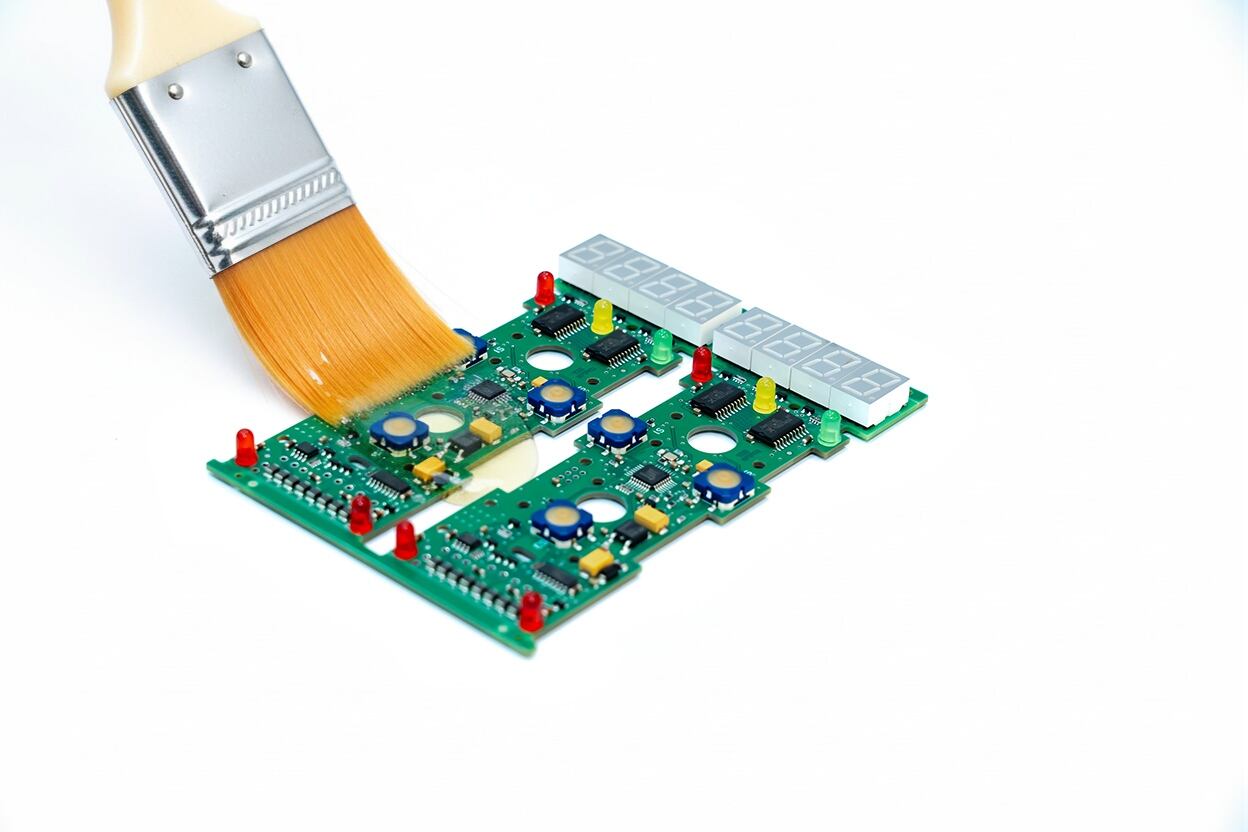

Conformal coating is a protective film applied to the surface of a printed circuit board (PCB). It acts like a protective layer around electronic components, tightly encasing the circuit board's components and circuitry, shielding them from moisture, dust, chemicals, temperature fluctuations, and vibrations.

Its core function is to enhance circuit insulation and slow down corrosion and aging, ensuring stable operation even in harsh environments. For this reason, conformal coating has become a key tool for ensuring the long-term operation of equipment in fields requiring extremely high reliability, such as aerospace, automotive electronics, and medical devices.

· Acrylic: Currently one of the most widely used conformal coatings, its greatest advantage is ease of application and removal for maintenance. It effectively blocks moisture and dust, making it suitable for consumer electronics with moderate protection requirements.

· Silicone: Flexible and resilient, it can withstand significant temperature fluctuations and mechanical stress. Even in high- and low-temperature environments like automotive engine compartments and aircraft interiors, it maintains coating integrity, making it an ideal choice for thermal expansion and contraction.

· Polyurethane: Offers outstanding chemical resistance and mechanical strength, providing long-lasting protection for PCBs in complex environments like industrial workshops, often prone to oils and chemicals.

· Epoxy: Its coating is hard, abrasion-resistant, and solvent-resistant, making it suitable for equipment that may frequently come into contact with hard objects or require solvent cleaning, such as industrial control panels and circuits within heavy machinery.

·Parylene: This vapor deposition coating evenly covers every detail of the PCB, including the gaps between pins and the base of solder joints. It offers exceptional moisture and chemical resistance and is often used in medical devices and military electronic equipment requiring extremely precise protection.

It effectively blocks the intrusion of moisture, dust, and chemical contaminants, reducing problems such as short circuits and component oxidation. This ensures long-term stable operation in humid and dusty environments, extending the lifespan of devices.

Conformal coating improves the insulation strength between different conductors in a circuit, allowing for more compact circuit layouts, which facilitates the trend toward smaller and thinner electronic devices.

Not only does it prevent environmental corrosion from damaging circuit boards, it also protects fragile components and solder joints from physical damage during handling, installation, and vibration.

1. Material Compatibility: Confirm the conformal coating's compatibility with the components and pad coatings on the PCB to avoid material reactions that could degrade component performance or cause coating detachment. When selecting a conformal coating, carefully consider the chemicals the equipment might be exposed to.

2. Application Process Details: Avoid dehumidification and peeling during application. Excessive coating thickness or improper temperature control during curing can also cause cracking. Uneven surfaces can also create "orange peel" patterns, compromising the protective effect.

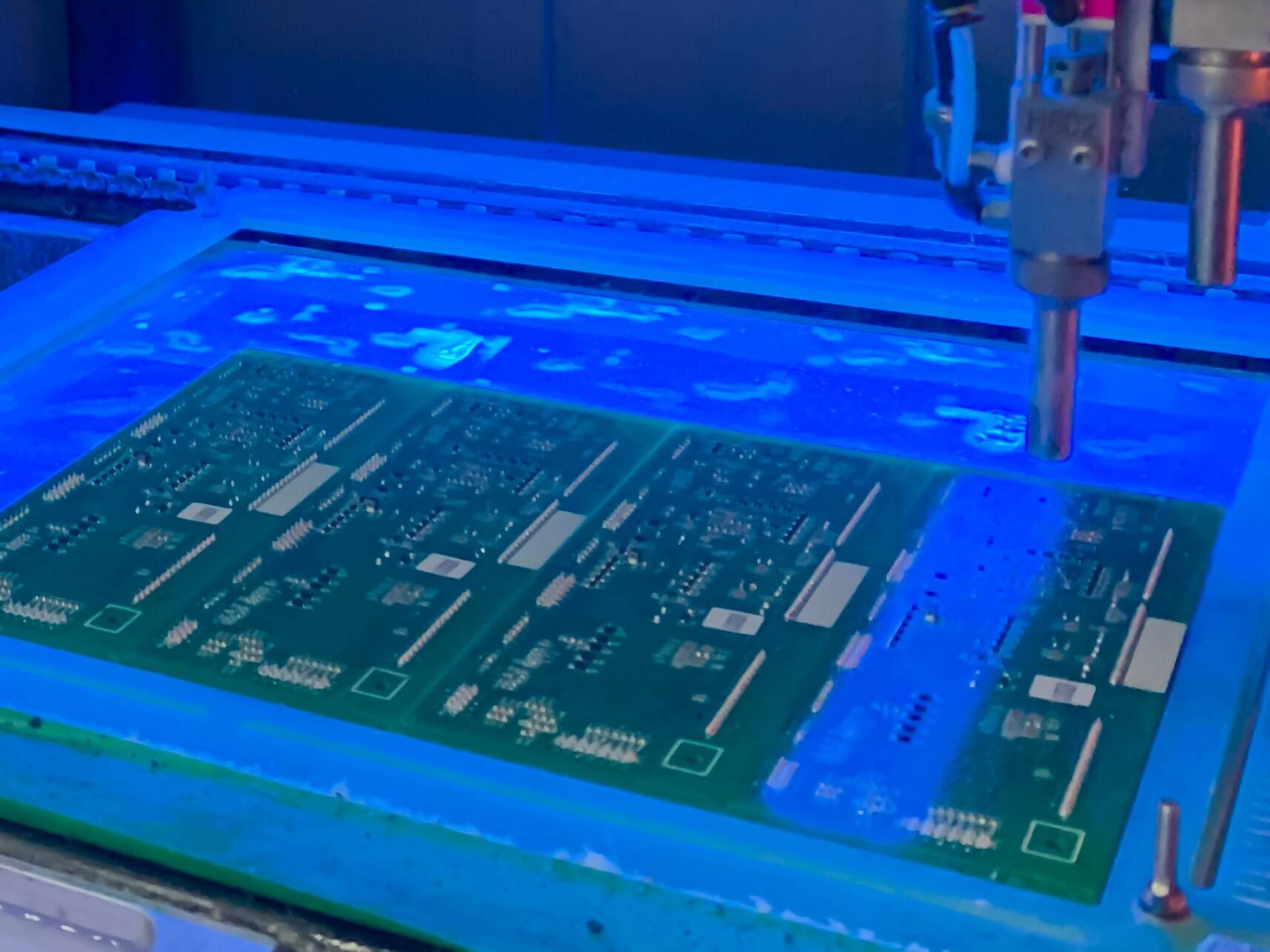

3. Controlling Coating Uniformity: Uneven coating thickness can result in localized weak protection. A professional team using precision equipment must control the coating process to ensure that every surface on the circuit board receives equal protection.

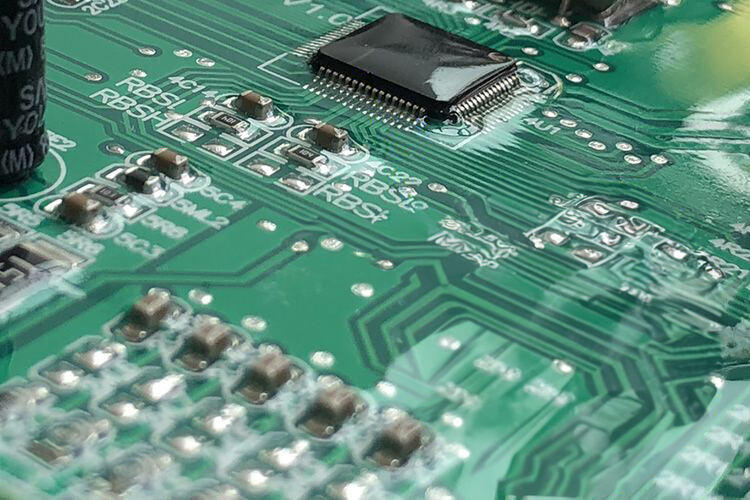

4. Inspection and Maintenance: Use UV light to inspect the coating for full coverage and any gaps. Use a microscope to inspect for potential hazards such as tiny bubbles. During subsequent maintenance, if the coating is damaged, carefully remove the damaged area, clean it, and then reapply to avoid damaging the original protective structure.

Professional conformal coating services go beyond simple coating. They encompass a comprehensive process from material selection and process adaptation to precise application and comprehensive testing, creating a solid and reliable protective barrier for PCBs:

· Compliance with Industry Standards: We strictly adhere to international standards such as IPC-CC-830, with clear specifications from material procurement to application processes, ensuring consistent and reliable coating quality for every batch.

· Extensive Cross-Industry Experience: We are familiar with the protective requirements of diverse industries, including automotive, aerospace, and consumer electronics. We can customize the most appropriate protective solutions based on the equipment's operating environment, ensuring compliance and safety.

· Flexible Support for Small-Batch Demands: We offer small-batch sample testing services with no minimum order quantity. Even for small-volume customizations, we ensure quality through meticulous craftsmanship, helping customers mitigate the risks of mass production.

When your product needs to maintain reliable operation in complex environments, conformal coating is that invisible line of defense. Choosing us will provide you with a professional, scenario-specific, and standard-compliant protection solution. From material selection to construction and testing, we provide comprehensive oversight, ensuring your PCB operates stably in a variety of harsh environments and guaranteeing long-term device reliability.