Rigid printed circuit boards (PCBs) are manufactured from a sturdy, unbending substrate. They maintain a permanent, fixed form, providing a stable foundation for device assembly, electrical interconnects, and physical support. Compared to foldable and deformable flexible PCBs, rigid PCBs offer mechanical strength and structural integrity, making them suitable for devices requiring stable structural support.

Most rigid PCBs are made of fiberglass (FR4) or other rigid laminate materials and reinforced with epoxy resin. Through chemical and thermal treatment, these materials will have stronger resistance to heat, chemical corrosion and stress. Fiberglass is the core of most rigid PCBs. In addition, electronic components such as capacitors, chips, resistors, etc. are also added and soldered to achieve the proper flow of current.

Feature |

Capability |

| Substrate Materials |

FR4 Polyimide (PI) film (12.7~127μm) |

| Adhesives | Thermosetting adhesive |

| Layer Stackup |

1 rigid + 2 flex + 1 rigid Flex copper layers ≤ 2 |

| Flex Layer Thickness | 12.7~127μm |

| Rigid Layer Thickness | 0.4~1.6mm |

| Copper Thickness | 12~70μm(0.5~2 oz) |

| Minimum Line Width/Line Spacing | 3/3 mil(76μm/76μm) |

| Minimum Drilling |

Flex laser drill ~0.075~0.1 mm Rigid mechanical drill ≥0.2 mm |

| Lamination |

Pre-alignment ±10μm Vacuum lamination 180℃ 3~5 Mpa |

| Drilling & Metallization |

CO2 laser for IVH Mechanical drill for through holes Electroless copper plating ≥1mil copper thickness |

| Etching | Line width/spacing ±10% |

| Coverlay | 25~50μm |

| Surface Finish |

Rigid area ENIG (0.05~0.1μm Au) Flex area OSP (≤0.5μm) |

| Minimum Bend Radius | ≥10× thickness |

| Finished Product Packaging | Foam/Bubble Pad/Anti-static Bag |

The reliability of rigid PCB depends on the synergy between each layer structure and the whole machine assembly. It mainly includes the following layers:

The most important part of the rigid pcb board structure is the substrate layer, which provides the basis for the PCB to provide strength and rigidity. The substrate is usually made of glass fiber reinforced epoxy resin (FR4) and is the "skeleton" of the entire circuit board.

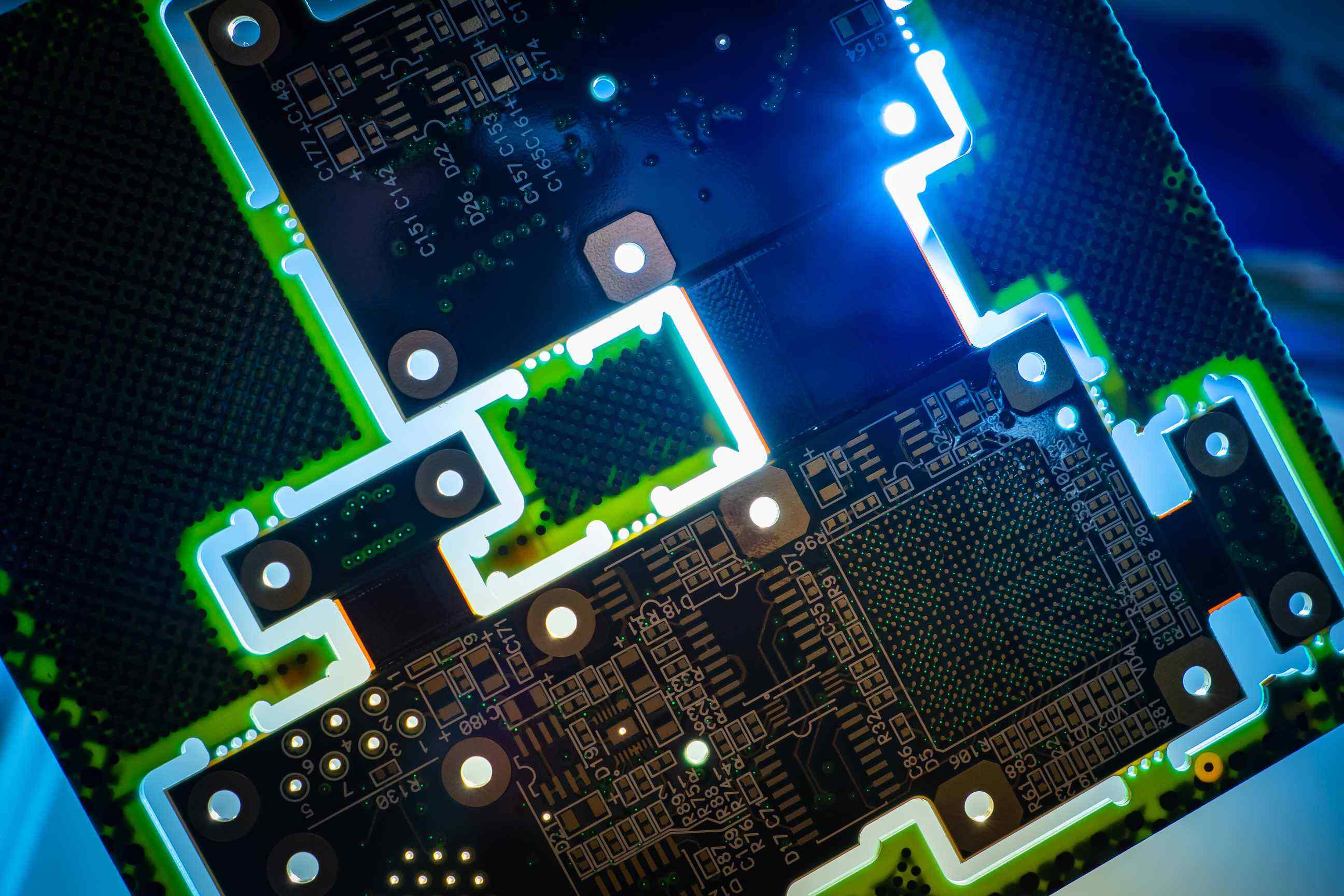

The copper layer connects each part and realizes the transmission of signals and power between the components in the board. The production method is to laminate a layer of copper foil on the rigid PCB after preparing the substrate such as FR4.

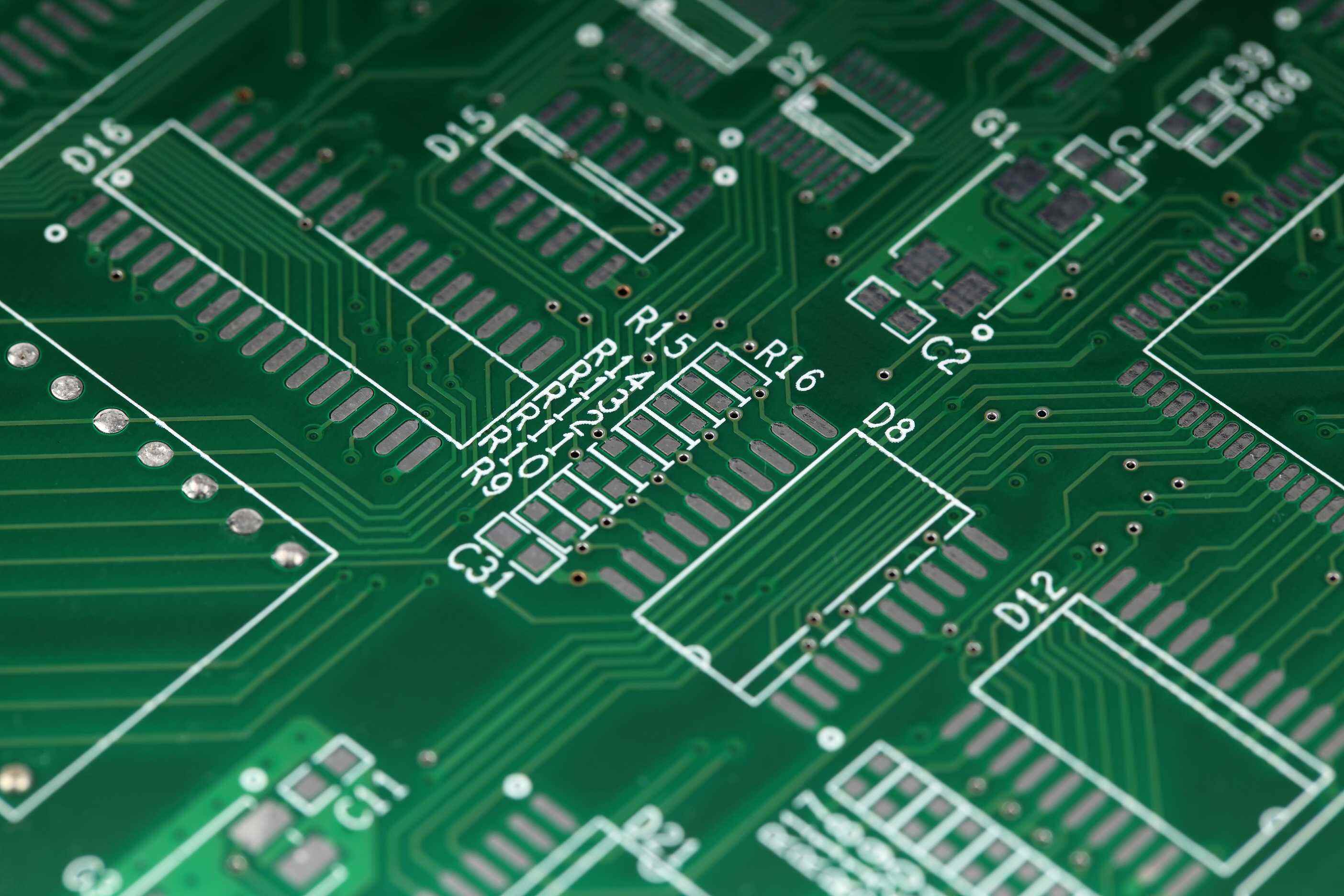

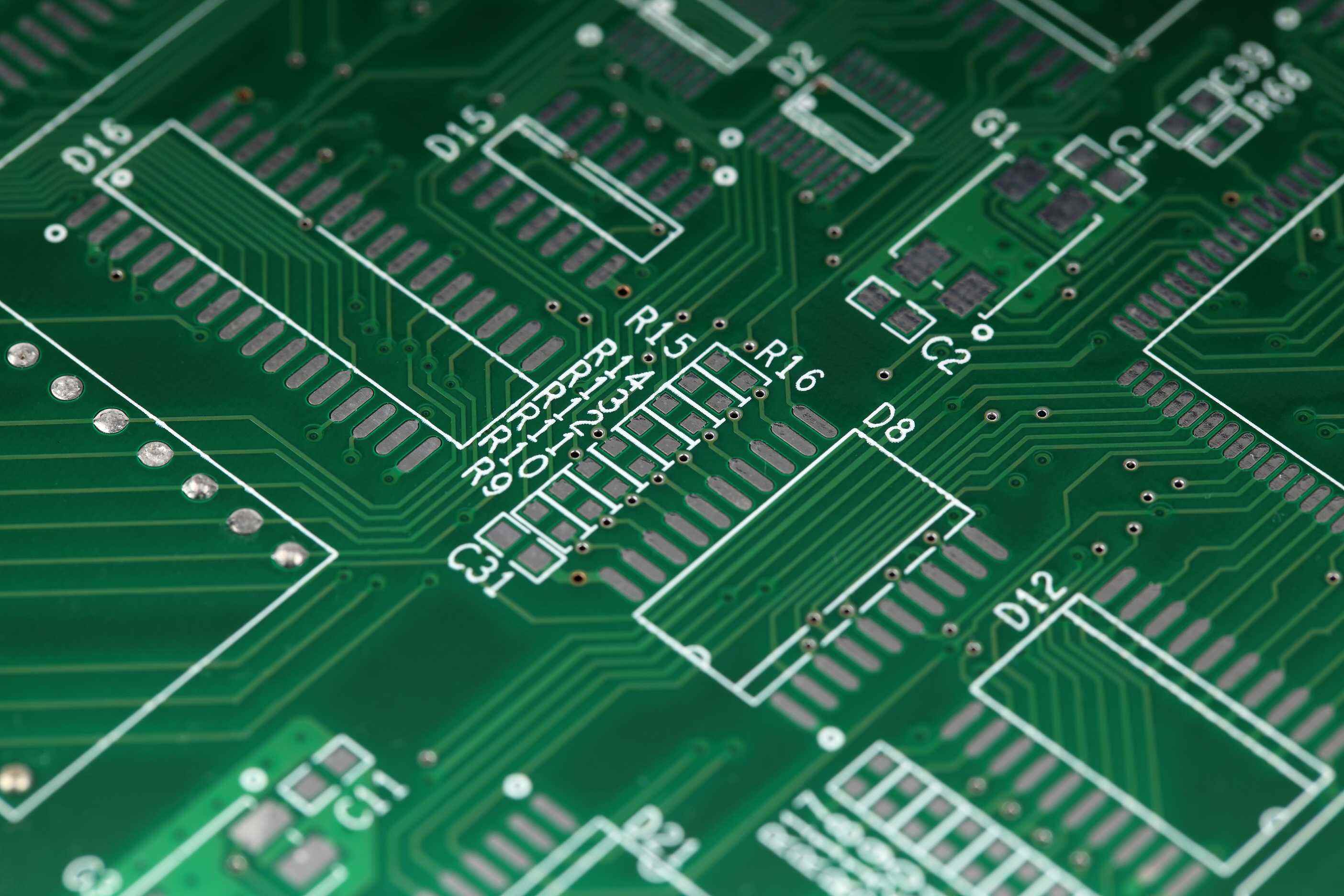

The commonly visible green surface is the solder mask, which not only provides an aesthetically pleasing appearance, but its main task is to protect the copper lines and prevent short circuits during the soldering process.

The silk screen layer is used to print information on the PCB board so that users can understand the board information. The content includes component labels, logos and reference symbols, etc., which is convenient for production, assembly and later maintenance.

There are many types of rigid PCBs, suitable for different application needs:

Single-sided rigid pcb board is the most basic type, it has a layer of copper on one side of the substrate. It is low cost, simple to produce, and suitable for low-density applications such as LED lights, calculators, etc.

Double-sided rigid PCB has copper layers on both sides, which can support more complex circuit designs and can be widely used in control systems, amplifiers and industrial equipment.

Multilayer rigid PCBs contain three or more copper layers separated by insulating materials. They are commonly used in high-density applications such as smartphones and medical devices.

Compared with ordinary PCBs, heavy copper PCBs can withstand higher current, mechanical stress and thermal load, and are suitable for power supply equipment and high-power applications.

Tg stands for glass transition temperature. High Tg PCBs can withstand high temperatures (>170°C) and are suitable for the automotive and aerospace industries.

High-Frequency rigid circuit board are primarily suitable for high-frequency signal transmission and are often made of low-loss materials such as PTFE (Teflon) to ensure signal integrity.

Based on aluminum or copper, it has better thermal management capabilities and is widely used in LED lighting, power systems and high-power automotive electronics.

Usually, we can only manufacture single-layer aluminum substrates and double-layer aluminum substrates. Due to the limitations of the manufacturing process, multi-layer aluminum substrates are difficult to manufacture, so they cannot meet the needs of complex multi-layer designs.

Metal aluminum materials have high rigidity and low softness, and are not as flexible as polyimide or polyester substrates. Therefore, they are not suitable for applications that require repeated bending.

The thermal expansion coefficient of aluminum substrates is relatively high, which is different from some components and solder materials. The mismatch of the thermal expansion coefficients of the two can easily lead to solder joint damage or delamination, affecting overall reliability.

Compared with ordinary substrates, the metal properties of aluminum substrates require more time to consider during manufacturing and assembly, which will increase process complexity and cost.

Although aluminum substrates have significant advantages in thermal management, compared with traditional FR4 materials, aluminum-based PCBs have higher material costs, special manufacturing processes and surface treatment requirements, so the overall manufacturing cost increases.

1. Rigid Structure: Primarily made of fiberglass, this ensures the board remains stable and prevents deformation, providing support for product stability.

2. High-Density Circuit Design: Supports multi-layer structures, enabling complex circuits and high-density component layouts.

3. High-Precision Dimensional Control: Suitable for products requiring high precision, such as smartphones and medical devices.

1. Durability and Long Life: Rigid materials and structure enable long-term use in harsh environments;

2. Low Production Cost: Suitable for mass production, standardized processes, and short cycle times;

3. Ease of Automated Integration: Supports automated welding and assembly, improving productivity and consistency.

1. Computer motherboard: Rigid PCB can be used as the core of the motherboard to carry key components such as CPU, memory, GPU, etc.;

2. Consumer electronics: Widely used in daily appliances such as smartphones, TVs, microwave ovens, etc.;

3. Automotive electronics: Indispensable in electric vehicles and advanced driver assistance systems (ADAS);

4. Communication equipment: Rigid PCB has high signal stability and can be used in radio, mobile phones, routers and satellite communication systems.

IPC-A-600 and IPC-6012 are two key standards:

Meeting IPC standards requires strict quality control measures such as micro-sectioning testing, AOI optical inspection, short circuit and open circuit electrical testing, etc. Only in this way can the long-term reliability of rigid PCBs be ensured.

PCBally uses advanced manufacturing and quality control technology to provide single-layer, double-layer and multi-layer rigid PCBs of FR4, high Tg and metal-based materials. Each PCB complies with IPC-A-600 and IPC-6012 standards and widely serves multiple industries such as consumer electronics, aerospace, industrial automation, etc. If you are looking for a reliable rigid PCB supplier, please contact us now!

Rigid circuit board have covered every aspect of people's lives, from household appliances to high-end industrial systems. They have won wide application with their advantages of high strength, precise size, good stability, etc. With the continuous development of the electronics industry, rigid PCBs will continue to play its role.