The printed circuit board (PCB) is like a "thousand-layer cake", with multiple layers of copper foil circuits stacked together. To transmit electronic signals between different layers, you have to rely on "vias" - you can think of it as the green water pipe in "Super Mario", except that electricity flows in the water pipe, not water.

However, the wall of the newly drilled hole is resin and is not conductive, so a layer of copper must be plated on the hole wall so that electrons can pass through the layers of copper foil.

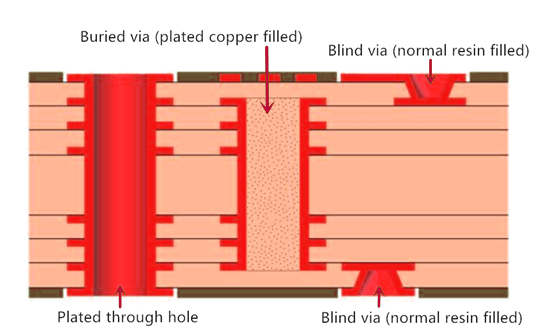

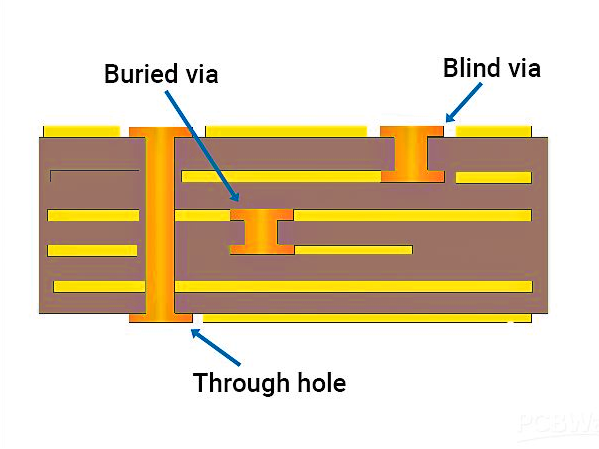

There are three common types of vias: through hole (PTH), blind via (BVH), and buried via (BVH). The following focuses on the latter two.

Look at the PCB against the light, the hole that can let light through is a through hole. It goes all the way from the top layer to the bottom layer, and is simple to manufacture and low in cost.The disadvantages are also obvious: if you only want to connect the 3rd and 4th layers, you have to drill through the entire board, just like installing an elevator from the 1st to the 6th floor in a six-story building, which only serves the 3rd and 4th floors, wasting space.

The blind hole starts from the surface of the PCB and only connects to the adjacent inner layer. The other end is hidden in the board and cannot be seen by the naked eye, so it is called "blind".During manufacturing, the drilling depth (Z axis) must be accurately controlled. Too deep or too shallow will affect the subsequent copper plating.

Common practice: first laminate, punch, and electroplate the local layers, and then press them together with other layers to form a whole board. For example, in a 2+4+2 structure, you can make the outermost two layers first, or you can make the 2+4 layers first, but both require extremely high-precision alignment equipment.

Burried vias only connect two or more inner layers, do not extend to the surface of the PCB, and are completely invisible from the outside.

Method: First punch and electroplate the inner core board, and then press it as a whole. There are more processes than through holes and blind holes, and the cost is also higher, but it can save space for more lines, and is often used in high-density interconnect (HDI) boards.

IPC standard recommends: The aperture of blind and buried vias should not exceed 6 mil (150 μm).

Advantages: More circuits can be packed into a limited number of layers or board thickness, making mobile phones and computers smaller and smaller.

Disadvantages: Many processes, many tests, high precision requirements, and rising costs.