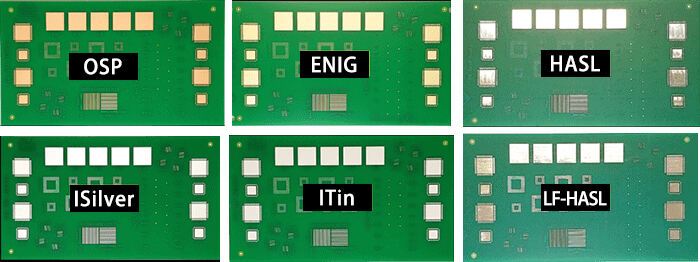

In PCB manufacturing, the commonly used surface treatment technologies are as follows:

Halting is to immerse the PCB in molten tin-lead solder, and then blow it flat with hot air to make the tin evenly adhere to the copper surface to form a layer of anti-oxidation and easy-to-weld coating. Blowing is to make the tin flat and prevent solder accumulation and short circuit.

There are two types of HASL: vertical and horizontal. The horizontal type is better and the coating is more uniform.

Process flow: first micro-etch (to make the copper surface rough for easy adhesion), then preheat, apply flux, tin spray, and finally clean.

Advantages: low cost, can be used everywhere, and can be repaired if broken.

Disadvantages: uneven surface, not suitable for small parts, thermal shock, bad for through-holes (PTH), poor wettability during welding.

OSP is an organic film grown on the surface of copper to prevent copper from being oxidized. This film is resistant to oxidation, heat and moisture, and can be removed by flux during welding to ensure the welding effect.

In the early days, imidazole and benzotriazole were used, and now benzimidazole molecules are mostly used. In order to be able to weld multiple times, copper ions will be added to make the film stronger.

Process flow: first degreasing, micro-etching, pickling, cleaning, applying organic film, and then cleaning.

Advantages: environmentally friendly and lead-free, smooth surface, simple process, low cost, and can be repaired.

Disadvantages: not suitable for through-hole (PTH), sensitive to the environment, and short shelf life.

ENIG is a thick layer of nickel-gold alloy plated on the copper surface. It has very stable performance, can prevent rust for a long time, and is suitable for complex environments.

The nickel layer can prevent the diffusion of gold and copper, otherwise the gold will quickly penetrate into the copper. The nickel layer is 5 microns thick, which can prevent high-temperature expansion and prevent copper from dissolving during lead-free soldering, making soldering more reliable.

Process flow: pickling, micro-etching, pre-dip, activation, nickel plating, and immersion gold. The whole process requires 6 chemical tanks and many chemicals, which is relatively complicated.

Advantages: smooth surface, strong structure, environmentally friendly lead-free, suitable for through-hole (PTH).

Disadvantages: Black pad problem may occur, high cost, and difficult to repair.

The difficulty of immersion silver is between OSP and ENIG. It will not "wear heavy armor" like ENIG, but the electrical properties are very good. It can be welded even in high temperature, humid and polluted environments, but the surface may become darker.

Immersion silver has no nickel layer support and is not as strong as ENIG. It is a replacement reaction, forming a thin layer of pure silver on the copper surface. Sometimes a small amount of organic matter is added to prevent corrosion and silver migration. These organic matters are very small, less than 1%.

Immersion Tin coating is very compatible with modern solder because solder is mainly tin. Early immersion tin was prone to tin whiskers, which caused problems during soldering. Later, organic additives were added to make the tin layer granular, which solved the tin whisker problem and improved thermal stability and solderability.

Immersion Tin can form a flat copper-tin compound layer on the copper surface. The welding performance is similar to that of tin spraying, but it does not have the problem of uneven surface like tin spraying, nor does it have the problem of intermetallic diffusion like ENIG.

Note: Immersion Tin boards cannot be stored for too long.