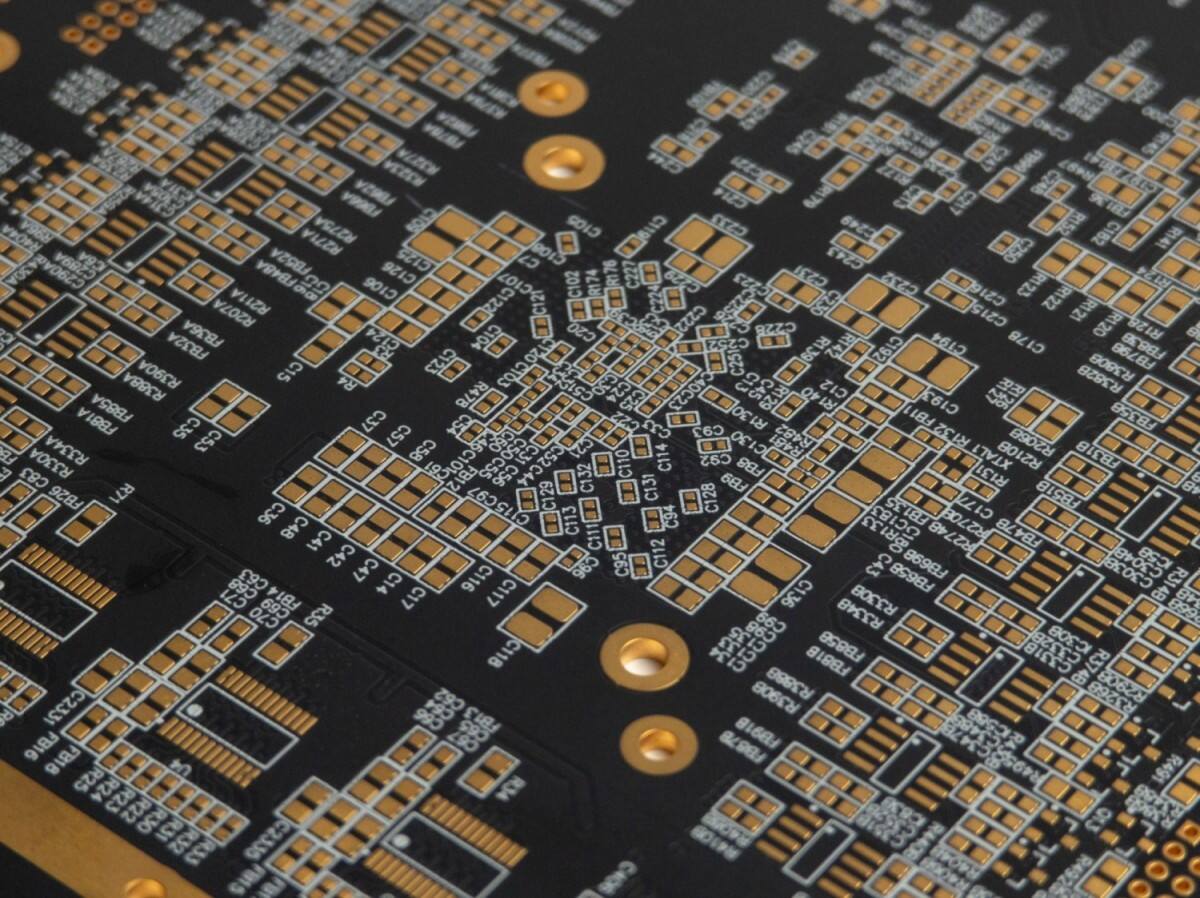

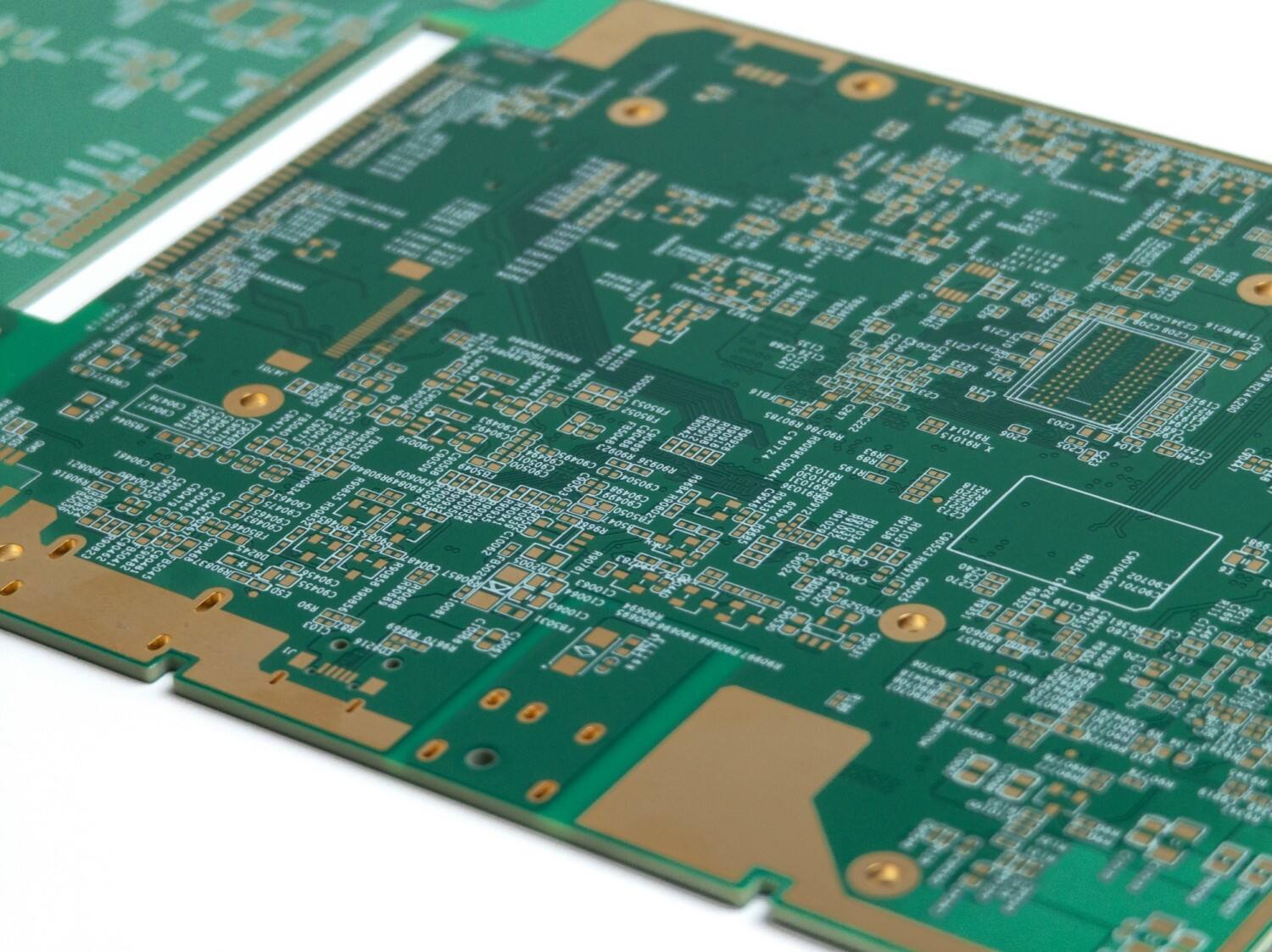

Silkscreen refers to the white text and numbers printed on the printed circuit board (PCB). White is the most common color because it is easier to identify on the green solder mask. But other colors can also be selected, such as blue, yellow, red and black.

Usually, the silkscreen contains valuable information, such as component number, device location, test point, company logo, PCB and PCBA part number and other manufacturer markings. A clear and effective silkscreen is like a detailed map, providing clear guidance for workers to assemble PCBs.

With this information, silk screen printing helps PCB assemblers quickly identify during assembly, testing and repair; it also provides necessary information identification for certification agencies.

Applicable to situations where the line width is greater than 7mil and the alignment accuracy is 5mil. This method is relatively simple and quick to apply and set up, but the accuracy is the lowest, and the printing effect is easily affected by factors such as ambient temperature, scraping pressure, ink viscosity, humidity, etc., so it is not recommended for high-precision PCB manufacturing.

Applicable to situations where the line width is greater than 4mil, and its process is similar to solder mask printing. Although it requires more time and ink, its accuracy and readability are significantly better than manual screen printing.

DLP is currently the most accurate, fastest, and most expensive screen printing method. It is printed using acrylic ink using an inkjet printer and cured with ultraviolet light after printing. But note that acrylic ink cannot be cured on silver-treated boards.

Of the three processes, LPI and DLP are currently the most widely used screen printing methods because they improve character clarity and support smaller text height and line width.

In short, silk screen plays a very important role in PCB design, proofing, assembly and testing. Before making PCB proofing or assembling, customers should fully communicate with PCB manufacturers about the details and requirements of silk screen to minimize printing errors.