What is a high Tg PCB?

In the world of printed circuit boards (PCBs), the glass transition temperature (Tg) is a key measure of the heat resistance of substrate materials. It marks the critical temperature point where the material changes from a hard, glassy physical state to a softer, rubbery state. In simple terms, when the ambient temperature is below Tg, the material remains rigid; once the temperature exceeds Tg, the material begins to soften and the mechanical strength and dimensional stability will drop significantly.

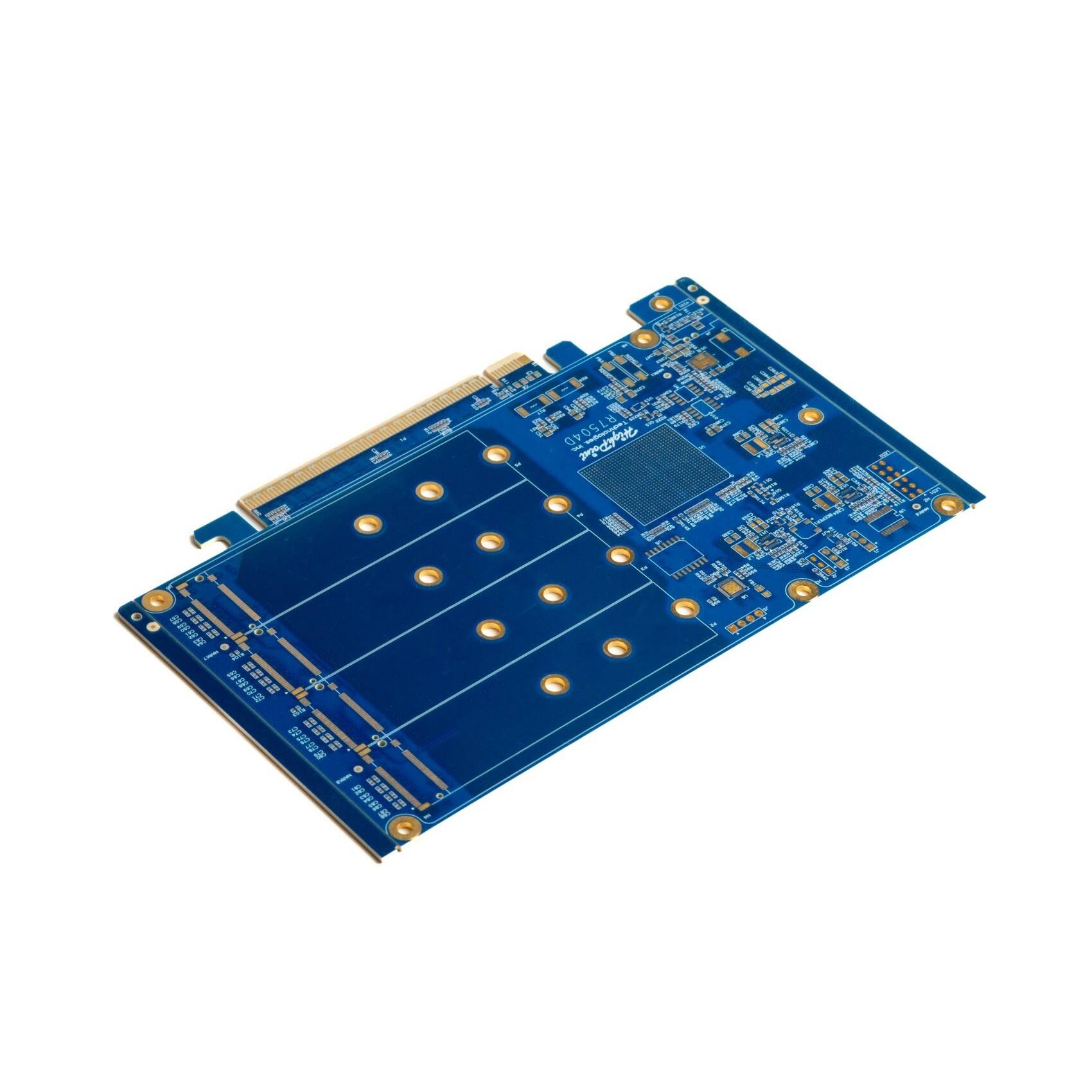

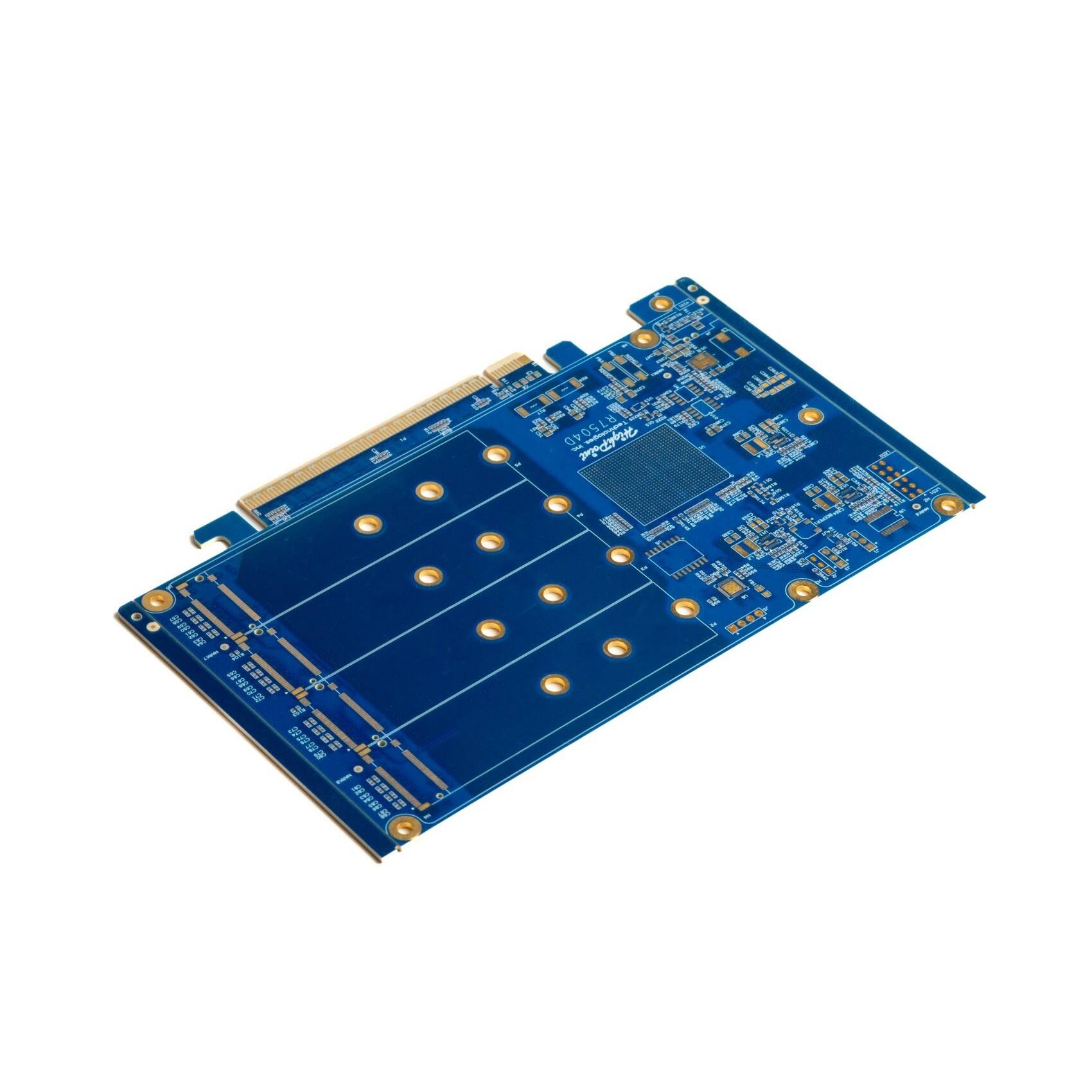

High Tg PCBs are printed circuit boards made of materials with high glass transition temperatures (Tg). These materials are designed to cope with high temperature working environments that ordinary PCB materials (such as standard FR-4, which usually has a Tg of around 130-140°C) cannot withstand. Even under severe thermal loads, high Tg PCBs can maintain their structural integrity, dimensional accuracy, and stable electrical performance, ensuring that electronic devices can operate reliably at high temperatures.

Core performance advantages of high Tg PCB

The reason why high Tg materials can cope with high temperature challenges is due to their series of excellent performance characteristics:

1. Excellent thermal stability:

- "Steel bones" at high temperatures: High Tg PCBs can still maintain good mechanical strength and hardness at temperatures much higher than ordinary materials. This means that the circuit board is not prone to warping, deformation or delamination, effectively preventing components from falling off and solder joints from failing.

- Performance does not "drop out": Its electrical performance can remain stable even in high temperature environments and will not deteriorate significantly due to temperature increases.

2. Low coefficient of thermal expansion (CTE):

- "Synchronous breathing" reduces stress: All materials expand when heated and contract when cooled. The copper wires and soldered components on the PCB also have their own expansion coefficients. If the expansion coefficient of the PCB substrate is too different from that of copper and components, huge thermal stress will be generated when the temperature changes drastically during the device startup and shutdown and welding process.

- High Tg solution: High Tg materials usually have a lower CTE that better matches copper and components. This is like letting the PCB substrate and copper wire/components "breathe synchronously" when the temperature changes, greatly reducing the risk of solder joint fatigue cracking, copper foil breakage or through-hole damage caused by inconsistent thermal expansion and contraction, and significantly improving the long-term reliability of the product.

3. Excellent dimensional stability:

- The low CTE and its own high rigidity work together to make the warping and shrinkage of high-Tg PCBs much lower than ordinary PCBs in the manufacturing process and use environment of multiple high-temperature pressing and welding. This is crucial for maintaining accuracy for multi-layer boards with many layers and complex structures, which directly affects the assembly yield and the performance of the final product.

4. Better high-frequency electrical performance:

- Many high-Tg materials (such as some modified epoxy resins, PPE, PTFE, etc.) have lower dielectric constants and loss tangents.

- "Highway" for signal transmission: Low Dk means faster signal propagation; low Df means less energy loss during signal transmission. The combination of these two enables high Tg PCB to better ensure signal integrity and quality in high-frequency and high-speed applications, reduce signal distortion and attenuation, and is particularly suitable for cutting-edge fields such as 5G, high-speed networks, and radio frequency.

5. Enhanced moisture and chemical resistance:

- High Tg materials generally have lower moisture absorption, which means less moisture is absorbed in a humid environment.

- Prevent problems before they happen: This not only reduces the risk of delamination caused by moisture absorption and expansion, but also reduces the possibility of electrical insulation degradation and ion migration in a humid environment, and improves the durability of the product in harsh environments.

Core Value Brought by High Tg PCB

The above performance advantages are directly converted into significant value in practical applications:

1. Reliability Leap:

Stable operation under high temperature conditions (such as automobile engine compartment, inside high-power power supply, and core area of industrial equipment), greatly reducing heat-related failures, significantly extending equipment life and overall system reliability.

2. Signal fidelity improvement:

Excellent high-frequency electrical performance is the cornerstone of high-speed digital circuits and RF applications, ensuring clear and accurate transmission of key signals.

3. Application boundary expansion:

Breaking through the temperature limit of traditional PCBs, enabling electronic devices to operate reliably in more stringent high-temperature environments, opening up new application areas.

4. Manufacturing yield and precision guarantee:

Excellent dimensional stability is the prerequisite for manufacturing high-density interconnects (HDI) and complex multi-layer boards, improving production efficiency and product consistency.

5. Long-term durability:

Combined with high temperature resistance, moisture resistance, and chemical resistance, it provides longer-term protection for electronic devices and reduces maintenance costs.

Guide to Tg temperature grade classification of PCB materials

Based on heat resistance, PCB substrates are usually divided into different grades according to Tg values to meet diverse needs:

1. Ordinary Tg: Tg ≥ 135°C

- Representative materials: Standard FR-4 epoxy resin.

- Applicable scenarios: Most consumer electronics, office equipment and other conventional temperature environments.

2. Medium Tg: Tg ≥ 150°C

- Performance characteristics: Better heat resistance than standard FR-4.

- Applicable scenarios: Applications with slightly higher requirements for thermal performance, such as some industrial control equipment, mid-range communication equipment, etc.

3. High Tg:

- Tg 170°C: Suitable for continuous medium and high temperature environments, such as automotive electronics and industrial controllers.

- Tg 180°C: Better thermal stability, commonly used in communication base station equipment, servers, and high-reliability consumer electronics.

- Tg 200°C: High heat resistance, usually with better thermal conductivity, suitable for aerospace electronics, high-end industrial equipment, and high-power LED lighting substrates.

- Tg 260°C+: Designed for extreme high temperature environments and high power density electronic devices.

- Tg 300°C+: The top heat resistance level of commercial materials currently available, used in the most demanding aerospace, military or special industrial high temperature scenarios.

Analysis of Common Key Materials for High Tg PCB

The realization of high Tg performance depends on a specific resin system. Here are several mainstream material types and their characteristics:

1. Polyimide (PI):

- Tg value: ≥ 250°C (very high)

- Characteristics: Excellent temperature resistance, excellent chemical corrosion resistance, good mechanical properties, low release of volatiles at high temperatures, and optional flexibility.

- Typical applications: aerospace, military electronics, high-temperature industrial sensors/controllers, flexible circuits.

2. BT epoxy resin:

- Tg value: 180°C – 220°C

- Characteristics: Excellent heat resistance, relatively low dielectric constant and loss, low moisture absorption, good processability. Balanced performance and cost in the FR-4 upgrade path.

- Typical applications: communication equipment, server motherboards, high-speed digital circuit boards, high-end consumer electronics.

3. Polyphenylene oxide (PPO):

- Tg value: 175°C – 220°C

- Features: Very low moisture absorption, very low dielectric constant and loss, excellent dimensional stability, good hydrolysis resistance.

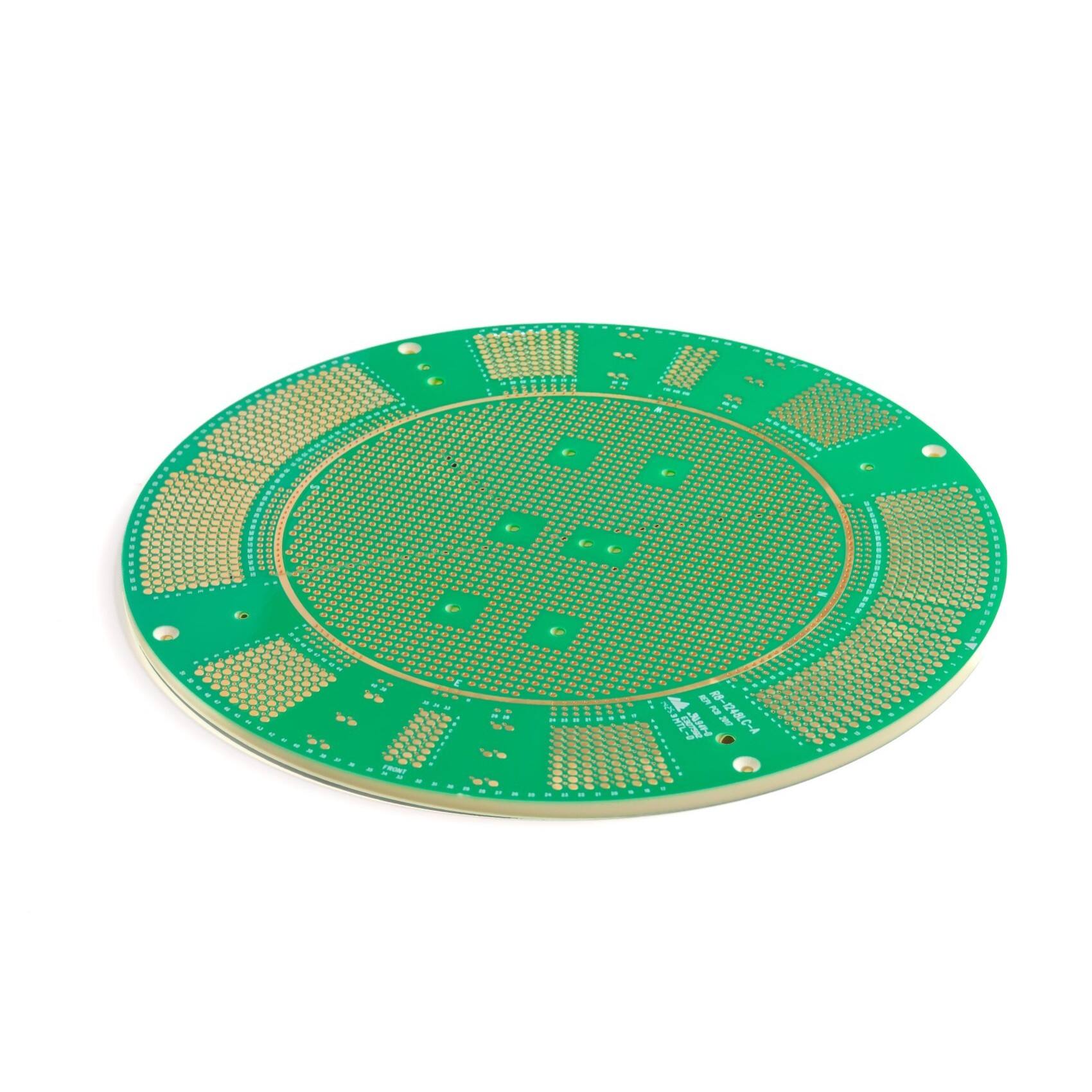

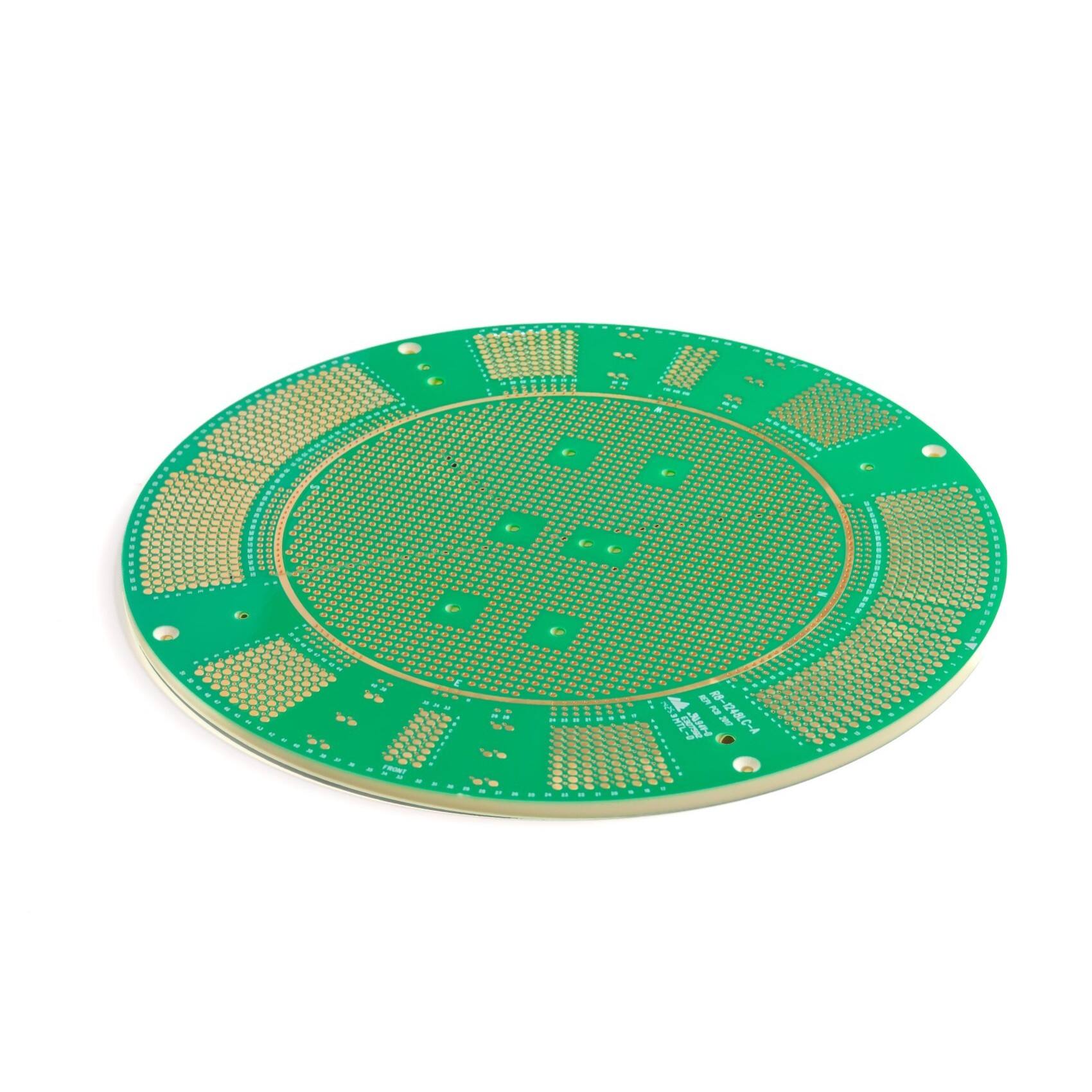

- Typical applications: High-frequency RF circuit boards (such as 5G antennas, radars), aerospace electronics, high-speed communication backplanes.

4. Liquid crystal polymer (LCP):

- Tg value: ≥ 280°C (very high)

- Features: Almost no water absorption, ultra-low and stable dielectric constant and loss, excellent chemical resistance, stable mechanical properties at high temperatures, can be made into ultra-thin flexible boards.

- Typical applications: High-frequency/high-speed connectors, 5G/6G, automotive radars, harsh environment sensors.

5. Polytetrafluoroethylene (PTFE) - often called "Teflon":

- Tg value: ≥ 250°C

- Characteristics: Ultra-low dielectric constant and loss, excellent chemical inertness, excellent high-frequency performance. However, pure PTFE has poor processability, high cost, relatively high CTE and anisotropy, and difficult drilling.

- Typical applications: High-end microwave circuits, radar systems, satellite communications, high-frequency test equipment.

6. Ceramic-filled PTFE:

- Tg value: ≥ 250°C

- Characteristics: Ceramic fillers are added to pure PTFE. Significantly improved stability, enhanced thermal conductivity, improved mechanical strength and hardness, and easier processing. The electrical performance is slightly inferior to pure PTFE but still very good.

- Typical applications: High-frequency RF/microwave power amplifiers, base station antennas, high-temperature and high-frequency equipment that requires good heat dissipation.

7. Hydrocarbon-based ceramic resin:

- Tg value: ≥ 200°C

- Features: Compounded by hydrocarbon resin and ceramic filler. Provides low dielectric constant, low loss, good thermal stability, excellent dimensional stability and processability, and the cost is usually lower than PTFE-based materials.

- Typical applications: High-speed digital circuit boards, high-frequency RF circuit boards, microwave equipment, automotive radar.

Why choose PCBally as your strategic partner for high Tg PCBs?

The manufacturing of high Tg PCBs is not a simple extension of ordinary FR-4 production. From material selection, lamination process control, drilling accuracy to final surface treatment and electrical testing, every link has put forward almost demanding requirements for temperature management and process accuracy. Slight deviations may lead to delamination, board explosion or substandard performance. PCBally is well aware of this. With 16 years of deep accumulation in the field of special PCBs, we are committed to becoming a solid and reliable "thermal management partner" behind your high-temperature applications.

PCBally provides you with not only circuit boards, but also a full range of protection solutions under high temperature challenges:

1. Accurate selection service:

Our team of senior engineers will recommend you the most cost-effective material solutions with the highest performance matching degree according to your specific application scenarios to avoid over-design or insufficient performance.

2. Precision process control:

Equipped with a fully automatic multi-stage temperature control press and an online monitoring system, relying on an exclusive process database, it ensures that each layer of lamination reaches the best cross-linking state and achieves zero-defect production.

3. Full-process thermal management:

From raw material storage to temperature traceability of key processes, to extreme environment simulation tests (TMA, T288, etc.), a complete thermal reliability guarantee system is built.

4. Flexible production services

Support 1 piece of sample to million-level mass production, provide full technical escort from DFM optimization to mass production, and achieve seamless connection.

5. Joint innovation support

Open material and reliability laboratories, share test resources, and jointly overcome extreme thermal management problems such as 800V electric vehicles and satellite electronics.

6. Transparent value delivery

Through large-scale procurement and yield control, long-term product value that exceeds price expectations is provided on the basis of cost transparency.

Choosing PCBally means choosing a PCB partner who has a deep understanding and extreme control of "heat". We promise to use cutting-edge technology, strict standards and sincere cooperation to ensure that your high-temperature electronic system remains as robust as before in harsh environments.

Start your "high-temperature worry-free" design now!

Welcome to contact the PCBally professional team to obtain high Tg PCB technical consultation and solutions for your application.