Printed circuit boards (PCBs) are widely used in consumer electronics, communications, and automotive applications. With the rise of information technology, automotive electronics, and the Internet of Things, China boasts thousands of PCB manufacturers.

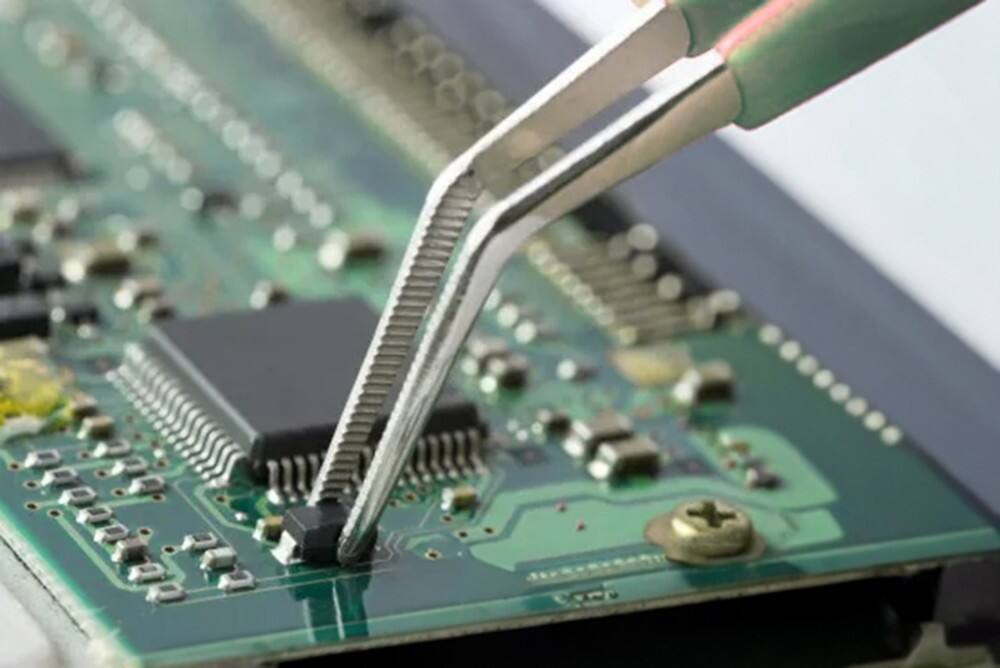

PCB assembly is the process of mounting electronic components onto printed circuit boards (PCBs). As demand for PCBs continues to grow, more and more customers are seeking manufacturers that offer fast turnaround times. This accelerated turnaround process, known as "Quick Turn PCB Assembly," can reduce lead times from several weeks to as fast as 24 hours, depending on design requirements.

Quick Turn PCB Assembly involves completing PCBs in a relatively short period of time. Conventional PCB turnaround times can take a week or longer, depending on design complexity. Quick Turn Assembly services, particularly in China, are leading the way not only in volume but also in quality.

The following factors significantly impact production cycle time: PCB layer count, thickness, design complexity, component count, and order quantity. Quick Turn PCB Assembly is typically used for prototypes or medium-volume production with tight deadlines.

Fast delivery means PCB manufacturers must provide PCBA services to their customers in the shortest possible time.

As a fast-delivery PCB manufacturer specializing in small- to medium-volume PCB manufacturing and assembly, PCBally not only delivers circuit boards within 24 hours but also completes PCB assembly within 4 hours.

PCBally is equipped with advanced production equipment and has established a comprehensive and scientific quality management system. For 16 years, we have earned widespread customer recognition for "best product quality," "most competitive pricing," and "most satisfactory service."

PCBally boasts experienced engineers and skilled production staff. We are confident in providing customers with reliable, high-quality, and fast-delivery PCB products at reasonable costs. Our five experienced teams, Sales, Engineering, Procurement, Production, and Quality, collaborate closely to ensure efficient delivery.

PCBally has established a comprehensive, user-friendly service process that allows us to quickly respond to individual customer needs and provide technical support, order tracking, and production progress inquiries. Our sales staff provides comprehensive support from order placement, production, and delivery to ensure customers receive high-quality products. We consider an order fulfilled only when it is 100% complete.

We understand that customers value a reliable and competitively priced partner. Therefore, our fast-delivery PCB assembly services feature customized pricing strategies tailored to your project, ensuring on-time completion and competitive pricing.

Why are more and more customers choosing fast-delivery PCB assembly? The key advantages are as follows:

Many manufacturers on the market claim to offer fast delivery capabilities through automated processes and engineering support. However, whether their actual delivery meets expectations depends on the following factors:

True fast delivery requires more than just fast product completion; it also requires ensuring a smooth production process and efficient delivery. Many companies publish PCB delivery schedules based on the number of layers on their official websites, allowing for a reasonable production schedule.

Even when pursuing fast delivery, quality should remain paramount. Whether the manufacturer has ISO quality system certification and complies with electronics manufacturing standards such as IPC and UL is crucial for evaluating the qualifications of a fast-delivery PCB manufacturer in China.

True fast delivery is difficult to achieve if the equipment is outdated and manual labor is predominant. A qualified manufacturer should have advanced, highly automated SMT production lines capable of handling complex PCB structures and component types, as well as the technical capabilities for prototyping and high-volume production.

Good customer service can effectively reduce misunderstandings and delayed decisions, thus preventing project delays. Collaboration is crucial for everyone, from the customer, design team, manufacturing engineers, to procurement personnel. Quick response, transparency, and proactive early warning are the core of effective communication.

Price is always a key factor in project selection. A quality manufacturer should be able to propose alternative materials or optimize processes to reduce costs while meeting delivery deadlines. Customers are advised to request detailed quotes from manufacturers to facilitate item-by-item evaluation and cost control.

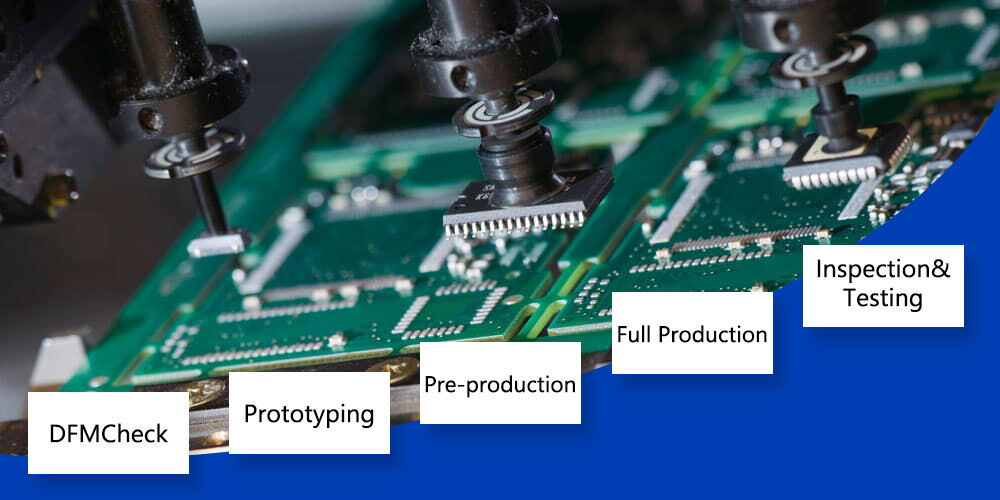

Customers submit Gerber files for a DFM review by the manufacturer to confirm design compliance with IPC standards and manufacturing capabilities, assess potential risks, and ensure fast delivery requirements are met.

Small-batch trial production verifies functionality and design quality. The design team and manufacturer collaborate to analyze issues and refine the design, a critical step in ensuring reliability for mass production.

After prototype verification, small-batch production begins to test the stability of the assembly line and manufacturing process and ensure mass production capability.

After the design and process are finalized, full-scale production begins.

Fast-batch PCB assembly delivery also requires comprehensive quality inspection, including automated optical inspection (AOI) and electrical testing, such as flying probe testing and in-circuit testing, to ensure that every delivered PCB meets functional and quality requirements.

With the growing demand for electronic products, high-speed, fast-delivery PCB assembly has become an industry trend. Finding a trustworthy PCB assembly supplier is crucial for transforming your designs into high-quality products. Choosing the right partner will help you meet project delivery deadlines and receive consistent, efficient, and high-quality circuit boards.