"A cable assembly is a connected unit composed of multiple wires or cables integrated with specific functions and structures. It can be considered the ""neural network"" of electronic devices. It not only transmits electrical signals and power, but also protects the internal wiring. From the complex wiring harnesses connecting computer peripherals to cars to the signal pathways in aerospace equipment, it's found in a wide range of electronic systems.

These assemblies are often covered with a specialized sheath, acting like a protective shield for the wires. This shield protects against dust and moisture, and absorbs the stresses of mechanical vibration and strain, ensuring stable connections in both everyday and extreme environments. The reliability of a cable assembly is directly linked to the operational efficiency of the entire electronic system.

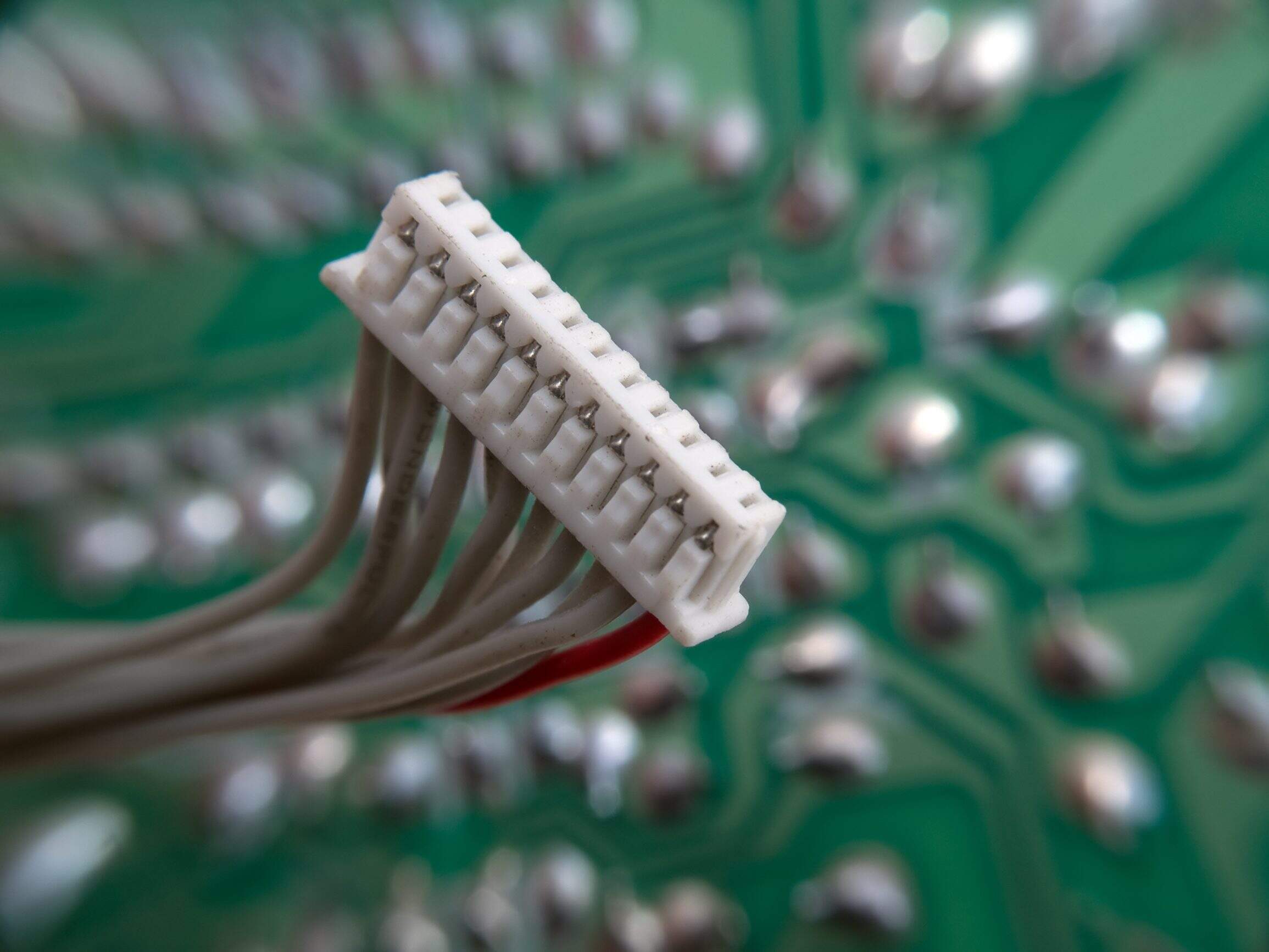

· Ribbon Cables: These consist of multiple parallel conductors, resembling a neatly arranged bundle of wires. Their advantages include space savings and simplified wiring. They are often used in applications where space is limited, such as inside computers, and where multiple lines need to be transmitted in parallel.

· Coaxial Cables: These cables have a central conductor as their core, surrounded by an insulation layer, a shielding layer, and a jacket, forming a structure similar to "concentric circles." This design provides excellent high-frequency signal transmission and interference resistance, making them widely used in communication networks, radio frequency equipment, and other fields.

· Multi-Conductor Cables: These cables contain multiple sets of independently insulated conductors, capable of transmitting multiple signals simultaneously. They are used in applications ranging from audio transmission in sound systems to multi-channel signal exchange in industrial control systems.

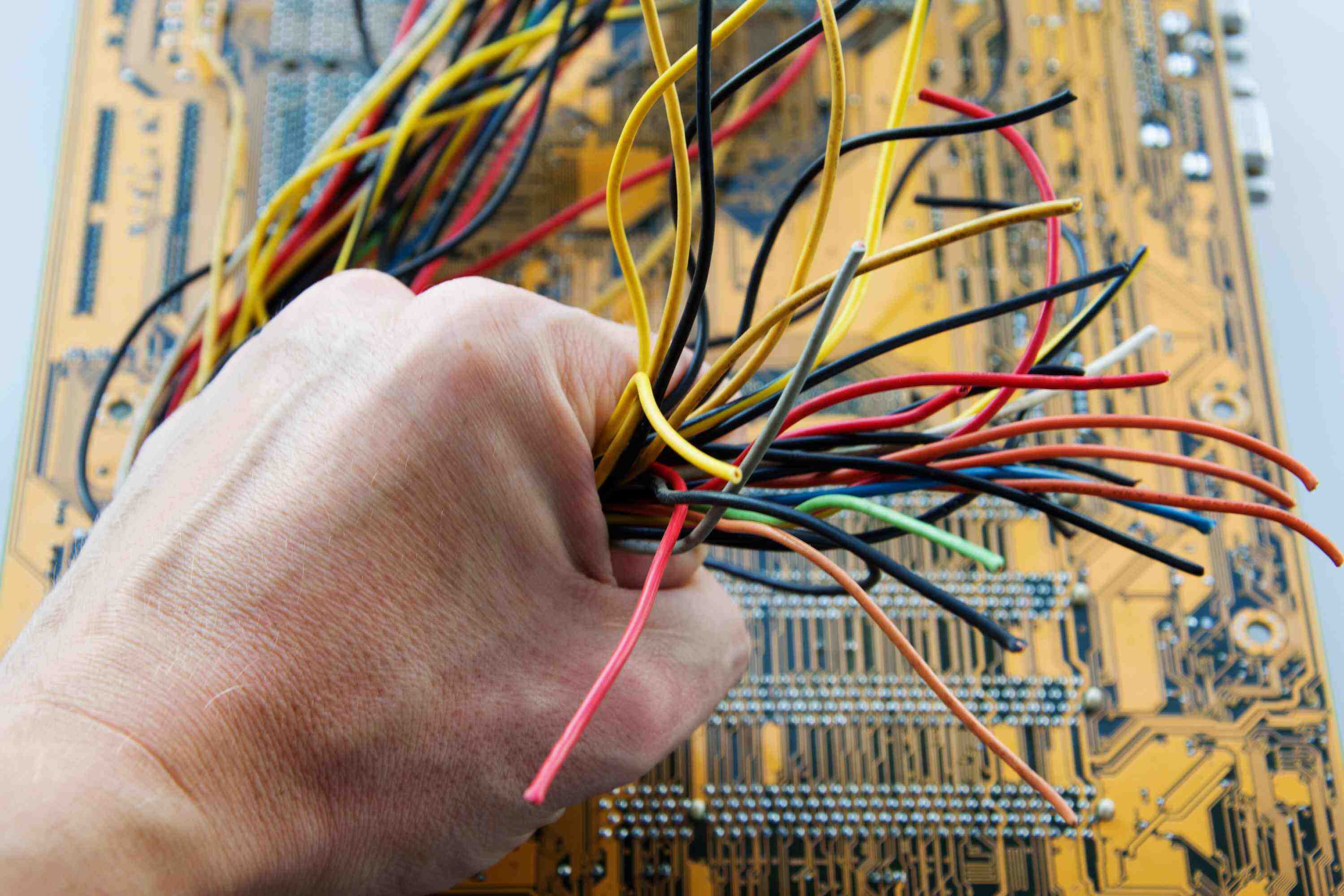

· Complex Wire Harnesses: These cables are composed of a combination of various cables, connectors, and fasteners, resulting in a sophisticated structure. They are suitable for applications such as automotive and aerospace that require a large number of circuit connections and can maintain high reliability in harsh environments.

· Length Accuracy: The cable length must match the device layout—excessive length can lead to signal attenuation, while too short can cause breakage. Design requires precise calculations based on the actual path.

· Connector Compatibility: The connector must match the device interface, meeting not only mechanical dimensional requirements but also electrical performance. For example, high-current applications require thick-contact connectors, while high-frequency applications require shielding to reduce interference.

· Jacket Material Selection: The jacket material should be determined based on the operating environment: PVC is suitable for standard applications; heat-resistant rubber is suitable for high-temperature environments; and special corrosion-resistant materials are required for chemically corrosive environments.

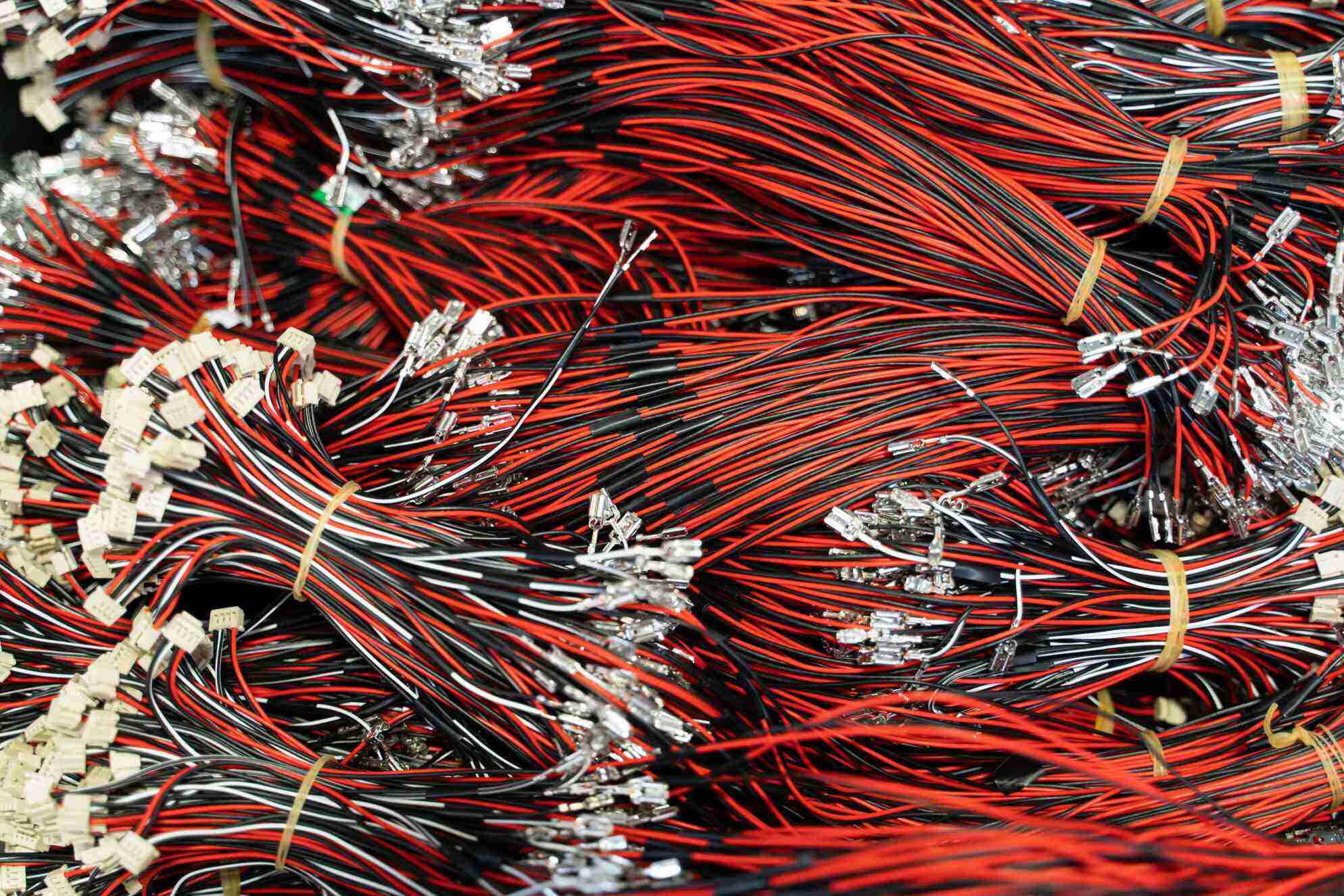

1. Wire cutting: Cutting the wire to the designed length with millimeter-level accuracy lays the foundation for subsequent processes;

2. Wire stripping: Precisely removing the insulation from both ends of the wire, with the exposed conductor length strictly controlled;

3. Assembly and arrangement: Sorting and bundling the wires according to the circuit diagram to ensure orderly wiring and prevent signal interference;

4. Connector installation: Securing the connectors to the wire ends through soldering or crimping to ensure secure contact and stable conductivity;

5. Jacketing: Adding an outer protective layer through extrusion or heat shrinking to enhance assembly durability;

6. Comprehensive testing, including conductivity, insulation, and functionality testing, ensures product compliance with design standards.

1. 20+ Years of Technical Accumulation: With 20+ years of experience in the industry, we have accumulated extensive design and manufacturing experience, efficiently handling everything from simple cable routing to complex harnesses, and have established a mature, full-process service system.

2. Outstanding Customization Capabilities: We specialize in small and medium-volume production and can tailor-make products to customer needs, eliminating the need to worry about "standardized products not being suitable."

3. Stringent Quality Control: From raw material selection to finished product testing, quality control is incorporated into every step to ensure the stability and reliability of delivered components.

4. Efficient Delivery Guarantee: We optimize production schedules, shorten delivery cycles while ensuring quality, and help customers' projects progress smoothly.

5. Significant Cost-Effectiveness: Through optimized material selection and process improvements, we control costs without compromising quality, offering more competitive pricing.

Cable assemblies, while seemingly simple, carry the "connectivity mission" of electronic systems. Choosing PCBally will give you a customized solution featuring "suitable design, reliable quality, and timely delivery," making every connection a solid foundation for the stable operation of the system.