PCB stencils are an essential tool in surface mount technology (SMT), used to precisely print the right amount of solder paste onto the designated locations on printed circuit boards (PCBs). The stencil is made of a thick, flat metal plate with apertures that correspond exactly to the pads on the board. Fiducial marks are also included on the stencil to serve as alignment references during the printing process. Stencil printing is a fast and practical method for depositing solder paste, suitable for mass production.

Stencil printing is the first step in the SMT process and is commonly used for both single-sided and double-sided PCB assembly. A successful SMT process requires optimizing key variables such as solder paste conditions and metal powder particle size, stencil thickness and opening size, and squeegee speed, pressure, and angle. The following are the specific steps for solder paste printing using a PCB stencil:

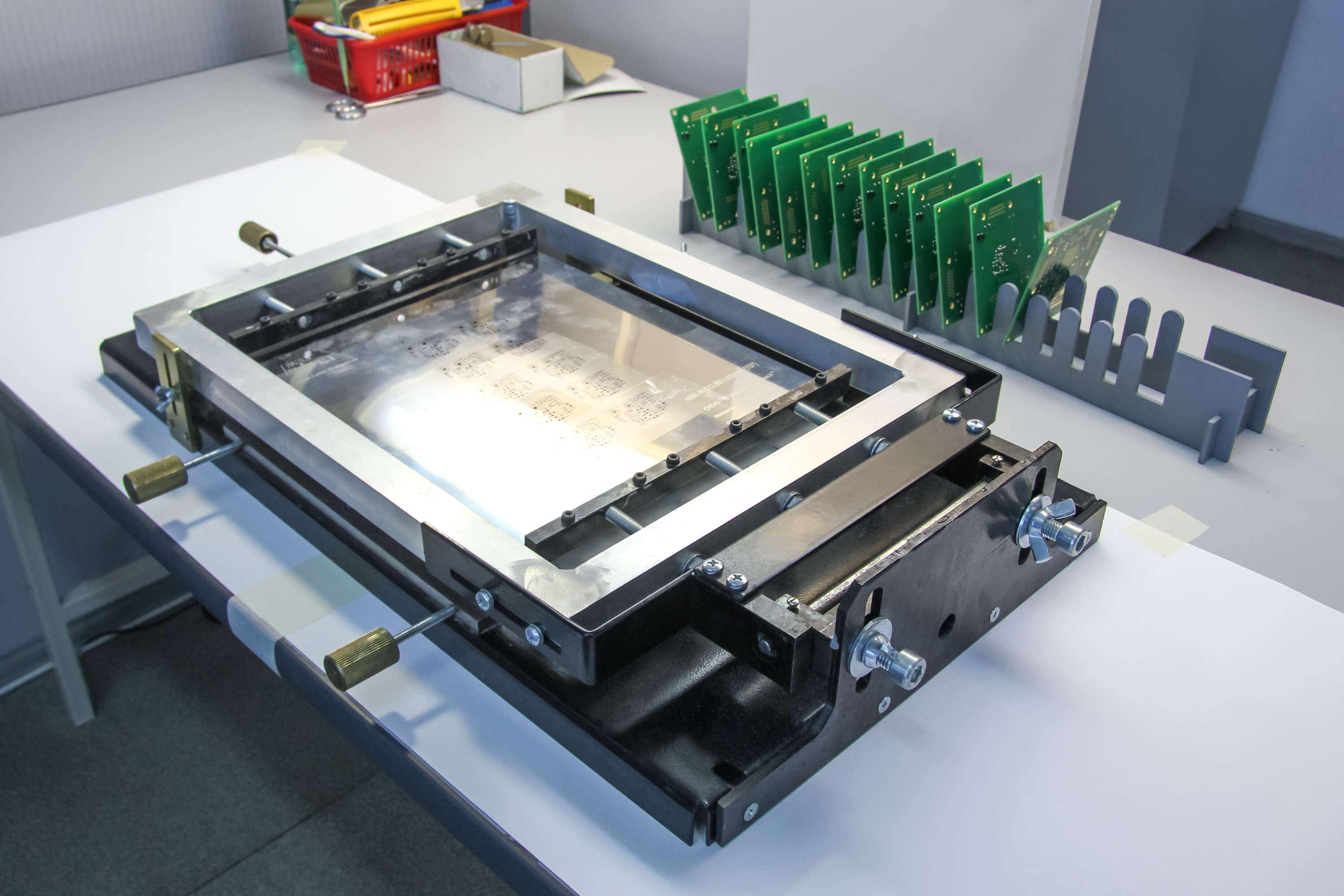

First, place the PCB on the solder paste printer and clamp the stencil used for PCB assembly to prevent movement. Then, use an automatic or manual printer.

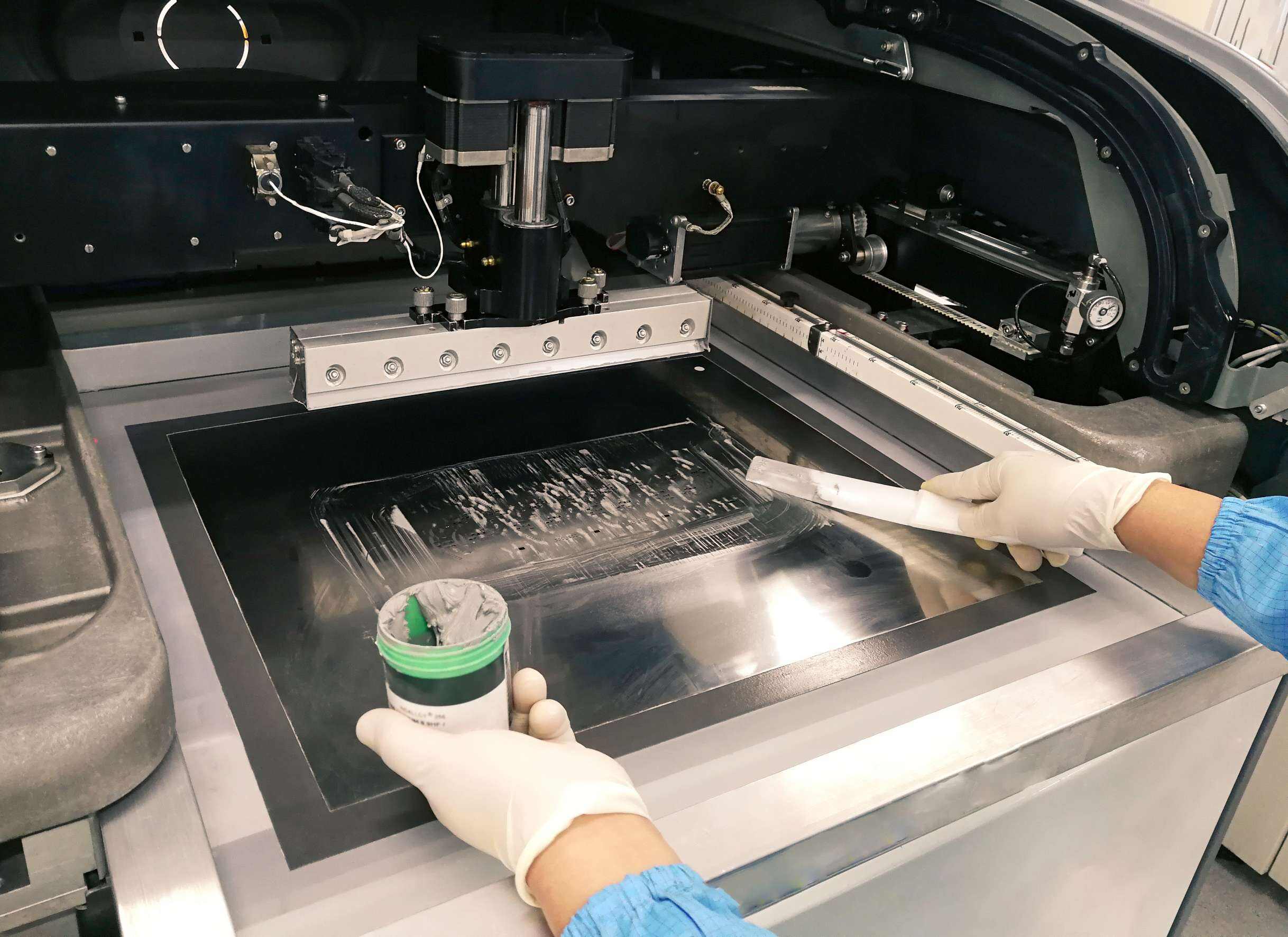

After the stencil is prepared, add an appropriate amount of solder paste to the PCB stencil. Be sure to thoroughly stir the solder paste beforehand, as it should be stored between 4°C and 10°C.(18px)

Clamp the PCB and align it with the stencil, aligning the openings in the stencil precisely with the pads on the board.

Move the squeegee along the stencil surface, evenly distributing the solder paste and pressing it into the openings, depositing it onto the PCB pads.

After solder paste printing is complete, separate the stencil vertically from the PCB, release the PCB clamps, and move the PCB to the next step. For fine-pitch pads, a linear separation is recommended to ensure printing accuracy.

After printing, optical inspection is required to confirm correct solder paste volume and alignment. This inspection is typically performed using the solder paste printer's built-in overhead camera, but standalone inspection equipment can also be used.

Stencil cleaning is essential for maintaining consistent solder paste printing quality. Cleaning removes solder paste residue adhering to the opening walls. Regular cleaning is essential to prevent solder paste from drying out and affecting the next print, especially for small components. Cleaning can be manual or automated; modern stencil printers are often equipped with a spray tank for automated cleaning.

Reasons to Choose PCBally as Your PCB Stencil Supplier:

• Familiar with stencils for all PCB types, especially those used for PCB assembly, we can provide you with satisfactory solutions.

• Supporting small and medium-volume PCB stencil manufacturing and assembly, with customized services.

• Providing efficient communication and technical support throughout the entire stencil PCB assembly manufacturing process.

• With a professional team and production workshop, we provide you with first-class custom PCB stencil services.

• Guaranteed high-quality stencil production throughout the entire process, ensuring superior stencil PCB assembly quality.

• Custom stencil production services can be provided based on your needs, with guaranteed on-time delivery.

To obtain your ideal stencil PCB, please contact us to place your order!