PCBA stands for Printed Circuit Board Assembly. During the mass production PCB assembly process, due to numerous variables in equipment and operators, it's impossible to guarantee that every circuit board will be fully qualified. Therefore, after assembly, various testing equipment and tools must be used to verify that the boards meet design specifications and technical parameters.

PCBA testing involves examining the electrical performance of assembled PCBs, verifying whether input and output values meet specified standards.

PCBA functional testing not only tests individual components but also evaluates the performance of the entire board in actual use. Functional testing ensures that virtually 100% of boards meet performance requirements before shipment, making it crucial for OEM/ODM customers.

PCBA in-line testing verifies that assembled boards meet design requirements. By using test points and host computer software or collecting test data from the boards, it determines whether the production process has been completed properly. It is a crucial inspection step after the SMT and DIP assembly processes.

To prevent defective products from being shipped, PCB functional testing is a crucial step that no reliable factory can skip. It can be said that the reputation of a company’s brand is closely related to the quality of its PCBA, so functional testing is often regarded as the ultimate link in the entire production process.

This is a preliminary inspection performed through manual visual inspection. While its advantages are simplicity and ease, its disadvantages are that it can easily miss minor defects and is difficult to classify and record data, making it increasingly unsuitable for modern high-density assembly.(18

AOI is suitable for detecting common surface defects such as polarity, missing parts, and misaligned parts. This method is intuitive and easy to diagnose, but it has limitations when it comes to detecting solder joint continuity.

This method has made significant advances in speed, accuracy, and reliability in recent years. It is particularly suitable for fixture-free testing of prototypes or small batches, and is currently the most efficient option.

Using specialized test equipment, a simulated operating environment is provided for the circuit board under test, testing its performance under various operating conditions to ensure proper function of the entire board.

This method offers low cost, high efficiency, and accurate testing, making it suitable for detecting open and short circuits. However, this method does not support functional testing and the cost of using fixtures is high, so you need to weigh the pros and cons before deciding whether to adopt it.(18

The following equipment is commonly used in PCB assembly testing:

ICT testing can detect opens, shorts, and component damage, offering a wide range of applications and simple operation. It can also accurately locate fault points, facilitating repairs.

This provides a simulated operating environment for the PCB under test, testing its operating parameters under various design conditions to verify the proper functioning of the entire board.

This simulates the actual product environment through high and low temperatures, hot and cold cycles, and power surges, thereby identifying potential soldering defects and component parameter mismatches. This testing helps eliminate defective products and verifies the long-term stability and reliability of the PCB.

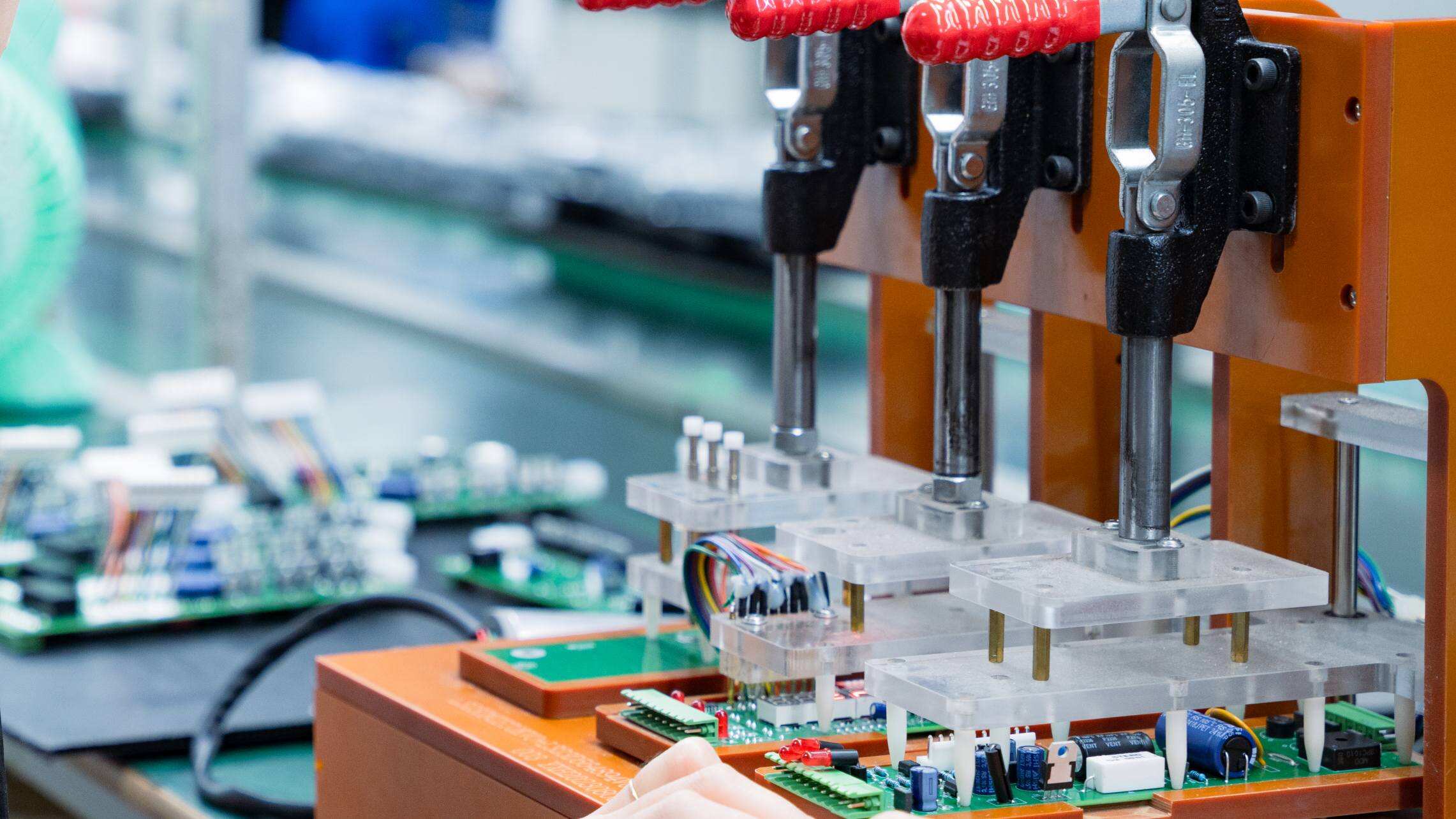

The principle of a PCBA test fixture is very simple: metal probes connect to pads or test points on the PCB. After powering the board, the test circuit is powered on and key parameters such as voltage and current are measured to determine whether the test circuit is functioning properly.

PCBA test fixtures are custom-made based on the PCB size, test point locations, and test parameter requirements. They are typically constructed from acrylic, plastic, metal probes, a display, wires, and a simple control circuit board.

PCBA test fixtures are widely used throughout the custom PCB assembly process, particularly for testing the functionality of the entire board after SMT and DIP placement.

• ICT Testing: The test fixture's probes contact test points to verify that the entire board is properly soldered.

• FCT Testing: Verifies that the entire board functions as expected.

• Production Efficiency and Qualification Rate: The quality of the test fixture directly impacts the efficiency and pass rate of ICT testing. Therefore, PCBA manufacturers place extremely high demands on the accuracy and stability of the test fixture. Choose PCBally for PCBA Testing

As a PCB fabrication and assembly manufacturer, PCBally firmly believes that PCA testing is crucial for ensuring product quality. It confirms product performance, controls quality, reduces after-sales service and repair costs, provides customers with peace of mind, and fosters win-win partnerships