Halogen-free PCB is a circuit board that does not use halogen elements in the manufacturing process.

Ordinary PCBs often use halogen-containing materials, such as brominated flame retardants (BFRs) to prevent fire. However, halogens produce toxic gases (such as hydrogen chloride and dioxins) at high temperatures or when burned, which are harmful to health and the environment. Therefore, many industries have begun to use halogen-free materials to make PCBs.

• Reduced toxicity: Reduced toxic gas emissions, halogen-free PCBs reduce the harm of electronic waste

• Easier to recycle: Halogen-free materials are easier to recycle.

• Compliance with regulations: Comply with environmental regulations such as RoHS

• Stronger thermal stability: Halogen-free PCBs generally have better thermal stability and are suitable for high-temperature environments.

• Better electrical performance: With lower dielectric constant and loss factor, they are suitable for high-frequency signal transmission.

• Excellent mechanical properties: The halogen-free materials used generally provide stronger mechanical strength and reliability.

Based on materials, structures and uses, common types are:

The most common type, using glass fiber reinforced epoxy resin substrate, but does not contain halogen flame retardants.

• Material composition: glass fiber epoxy resin substrate, does not contain halogen flame retardants, flame retardant with phosphorus or nitrogen.

• Thermal properties: glass transition temperature (Tg) is about 150°C ~180°C.

• Electrical properties: good electrical properties and wide range of uses.

Suitable for high temperature environment, Tg is higher than ordinary FR4.

• Material composition: high Tg halogen-free epoxy resin.

• Thermal properties: Tg ranges from 170°C ~ 260°C.

• Electrical properties: low dielectric constant and low dissipation factor, suitable for high-frequency applications.

Excellent thermal stability and mechanical strength, suitable for harsh environments.

• Material composition: halogen-free polyimide resin.

• Thermal performance: Tg exceeds 200°C, and continuous operating temperature can reach 260°C.

• Mechanical properties: High mechanical strength, very stable.

Suitable for installations that require bending.

• Material composition: halogen-free polyimide or polyester film.

• Thermal performance: Good thermal performance, resistant to dynamic bending.

• Mechanical properties: Flexible and durable.

Designed for high-frequency circuits.

• Material composition: Use PTFE or ceramic filled substrate.

• Thermal performance: Excellent thermal stability (slightly lower than PI material).

• Electrical performance: Very low dielectric constant and dissipation factor, excellent signal integrity.

Used to enhance heat dissipation, halogen-free materials are used in the dielectric layer.

• Material composition: Aluminum/Copper core + halogen-free insulation layer.

• Thermal performance: Good thermal conductivity, suitable for applications with high heat dissipation requirements.

• Mechanical properties: Strong and reliable structure.

High line density, using advanced processes such as microvias and buried vias.

• Material composition: High-performance halogen-free materials (good electrical and thermal performance).

• Thermal performance: Suitable for high-density and high-heat applications.

• Electrical performance: Low dielectric constant and loss, good signal integrity.

Although halogen-free PCBs are increasingly used in medical, wearable devices and other products that are close to people, they still face challenges

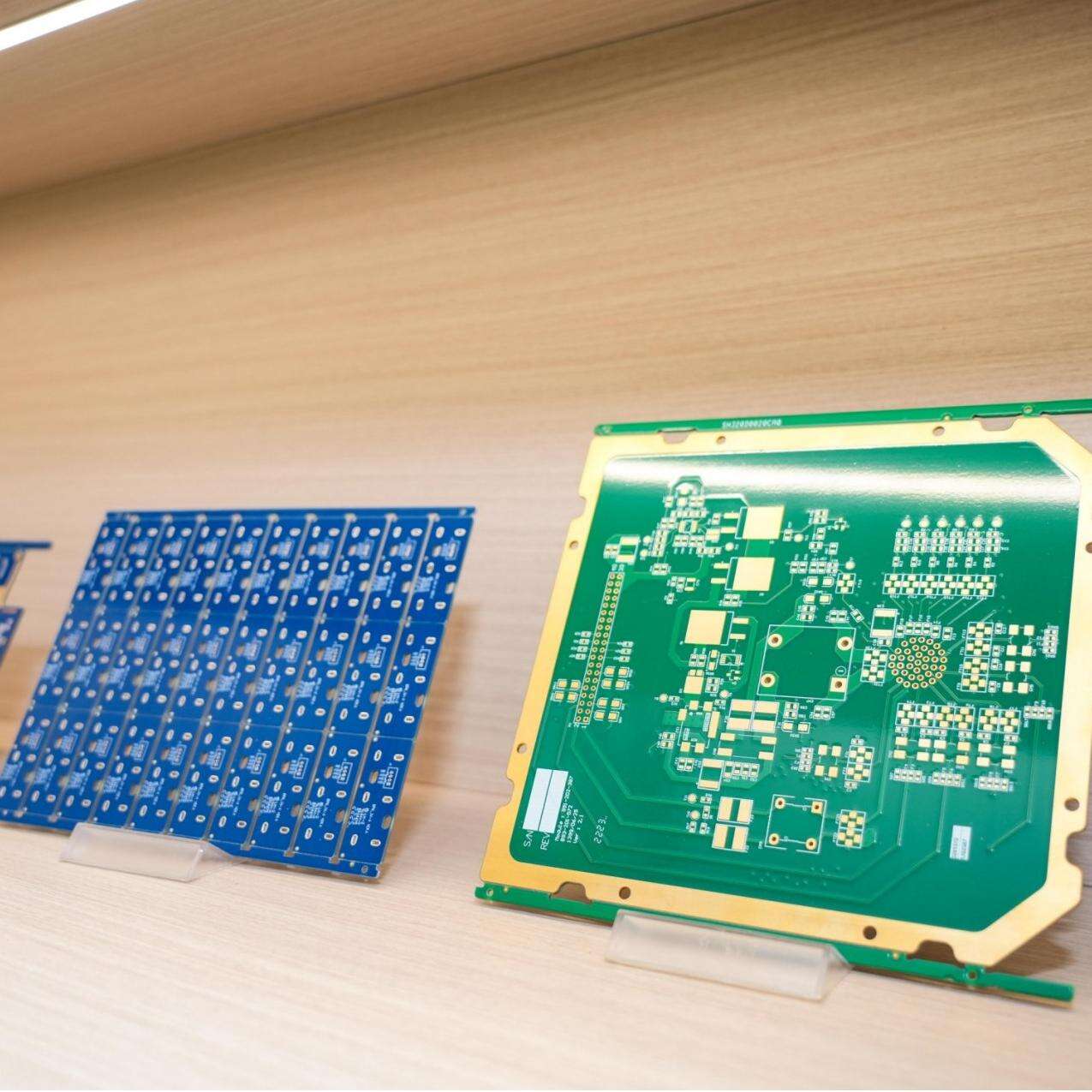

PCBally is one of the leading halogen-free PCB manufacturers in China, providing high-quality services with high cost performance: