Any electronics project places stringent demands on PCB quality. Our PCB First Article Inspection (FAI) is a critical step before mass production. Through comprehensive inspection and testing of the first finished PCB off the production line, we verify that it fully complies with design specifications. This helps prevent potential errors during mass production and lays a solid foundation for product excellence.

First Article Inspection (FAI) is a crucial quality control step in electronics manufacturing. Simply put, it involves comprehensively inspecting and testing the first PCB off the production line before mass production begins. This meticulous verification ensures that the manufacturing setup is accurate, from conformance to design dimensions and the quality of raw materials to the integrity of component assembly. This ensures that every indicator meets expectations, providing a qualified sample for subsequent mass production.

Our inspection process covers comprehensive verification, from physical properties to electrical performance:

1. Dimensional Accuracy Verification: We precisely measure critical PCB dimensions, such as thickness, hole diameter, and pad placement, in strict accordance with industry standards to ensure accuracy to the design drawing.

2. Electrical Performance Testing: We use specialized equipment to test the circuit's conductivity and insulation, troubleshooting hidden issues like shorts and opens, and ensuring the fundamental reliability of circuit functionality.

3. Component Matching Verification: We verify the correct component model, specifications, and mounting position against the bill of materials to prevent errors like incorrect or missing components.

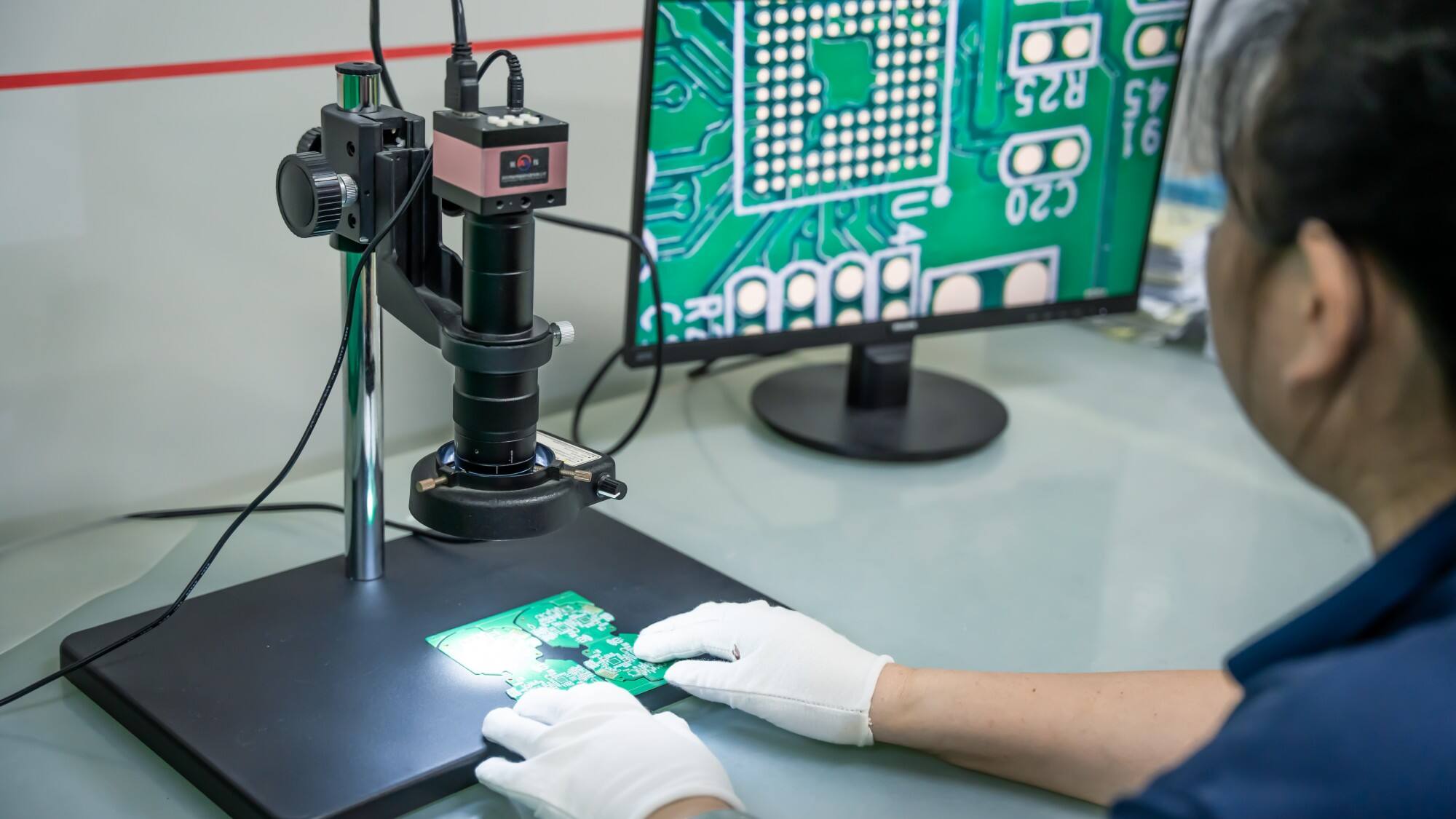

4. Soldering and Assembly Quality Assessment: We combine manual inspection with automated optical inspection (AOI) to meticulously check solder joints for fullness, the presence of cold solder joints and bridges, and the alignment of components to ensure that assembly processes meet standards.

5. Detailed Report Output: Upon completion of the inspection, we provide a clear and easy-to-understand report, clearly identifying deviations and providing improvement suggestions. This allows you to clearly understand the product status and facilitate rapid adjustments to the production process.

First-article inspection can be said to be the "bridge" between prototype and mass production. Doing this step well can effectively reduce risks and bring products to market faster and more reliably.

Our experienced inspection team and sophisticated equipment are familiar with industry quality standards and can provide customized inspection solutions for different PCB types. Whether it's small-batch prototype verification or first-article verification before large-scale mass production, we rigorously ensure every inspection is accurate and thorough.

If you're looking to control PCB quality from the source, learn about our first-article inspection services—ensuring that every PCB production starts with a "qualified first article."