Do you know "Teflon"? It is actually the brand name of polytetrafluoroethylene (PTFE). The Teflon PCB we are talking about is a circuit board made of this material. This kind of board has outstanding performance, especially in high-frequency scenarios, such as radar and radio frequency systems, which have high requirements for signal transmission. It is particularly suitable for use. This is mainly due to the characteristics of PTFE material: on the one hand, its biggest feature is the "inertness" of the surface - it does not stick to things, its chemical properties are particularly stable, and it does not react with other substances, so it has strong corrosion resistance; on the other hand, its excellent electrical performance can keep high-frequency signals stable during transmission, which is also the key reason why it is favored in high-end electronic equipment such as radar and radio frequency equipment, which have high requirements for signal quality.

For electronic devices, the "quality" and "speed" of signal transmission are lifelines, and Teflon PCB is top-notch in these two aspects:

Despite the excellent material properties of PTFE, converting it into a reliable circuit board requires a specialized manufacturing process that is significantly different from the process used for standard FR4 laminates:

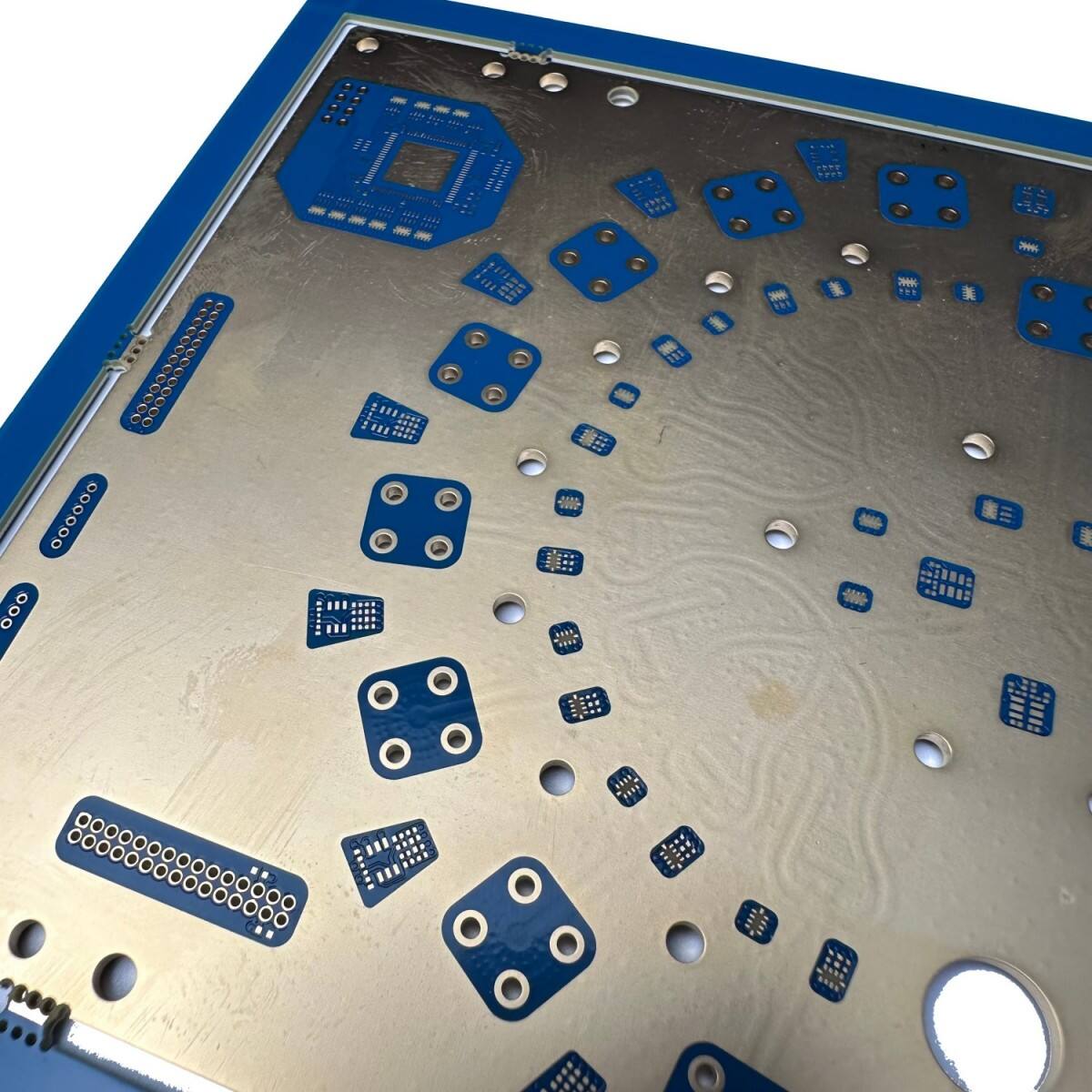

The Teflon substrate is particularly soft, and its surface is smooth and inert, which is not conducive to the adhesion of the copper layer. If you use a brush to clean the surface like ordinary circuit boards, it is easy to scratch. Instead, dedicated surface treatment processes such as sodium naphthalene etching or plasma surface activation are essential to activate the surface and create strong chemical bonding points for subsequent metallization.

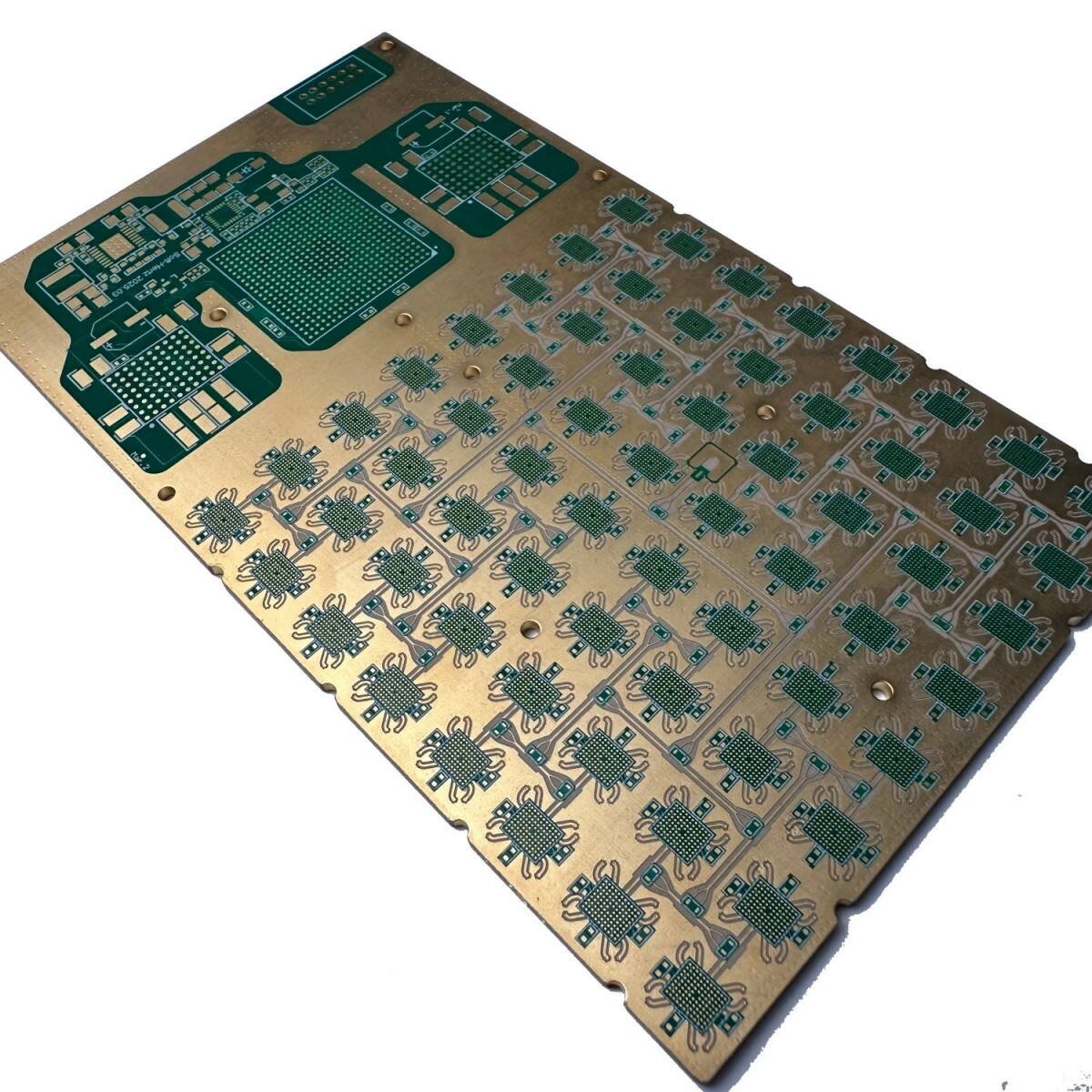

Ordinary drill bits are prone to material drawing and burrs when drilling Teflon. We have to use new drill bits with high cutting force and drill slowly. And ceramic fillers are often added to the material to enhance its drillability and laminate dimensional stability.

Pure Teflon material has a relatively high thermal expansion coefficient in the thickness direction (Z axis), and it is easy to "stretch and shrink" when the temperature changes. Therefore, the hole wall of the via must be plated with a copper layer with high tensile strength, just like adding a layer of "rebar" to the hole wall, otherwise the pad may fall off and the via is easy to crack.

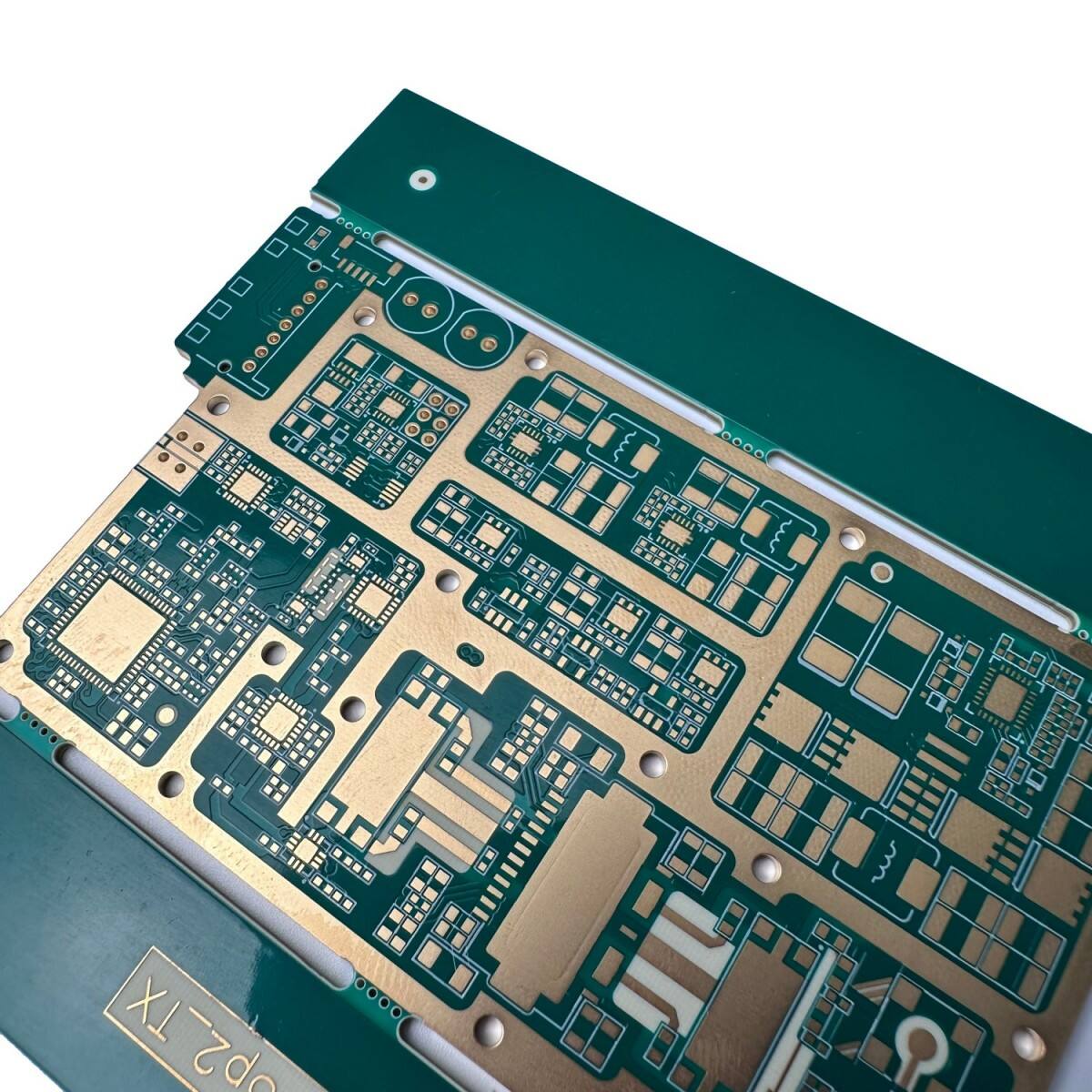

After etching, solder mask treatment must be done within 12 hours - this is because the Teflon surface is easily oxidized if exposed for too long. Before treatment, it must be thoroughly dried to remove moisture, otherwise the solder mask layer is easy to bubble, affecting subsequent use.

1. "Zero jamming" signal transmission: low dielectric constant + low loss, high-frequency signals run fast and stable, especially suitable for radar, RF system and other signal-sensitive equipment;

2. "No short board" environmental adaptability: from extreme cold to high temperature, from chemical corrosion to humidity, it can withstand all kinds of extreme environments, saving the trouble of frequent maintenance;

3. Lifespan far exceeds that of ordinary circuit boards: strong weather resistance, material is not easy to age, one-time investment can replace ordinary circuit boards for several years, which is more cost-effective in the long run.

1. It is difficult to process and requires special equipment and experience, so the cost is higher than that of ordinary FR-4 circuit boards;

2. The thermal expansion coefficient must be considered during design, otherwise problems such as via cracking are prone to occur;

The process requirements for manufacturers are high, and not just any manufacturer can do it well.

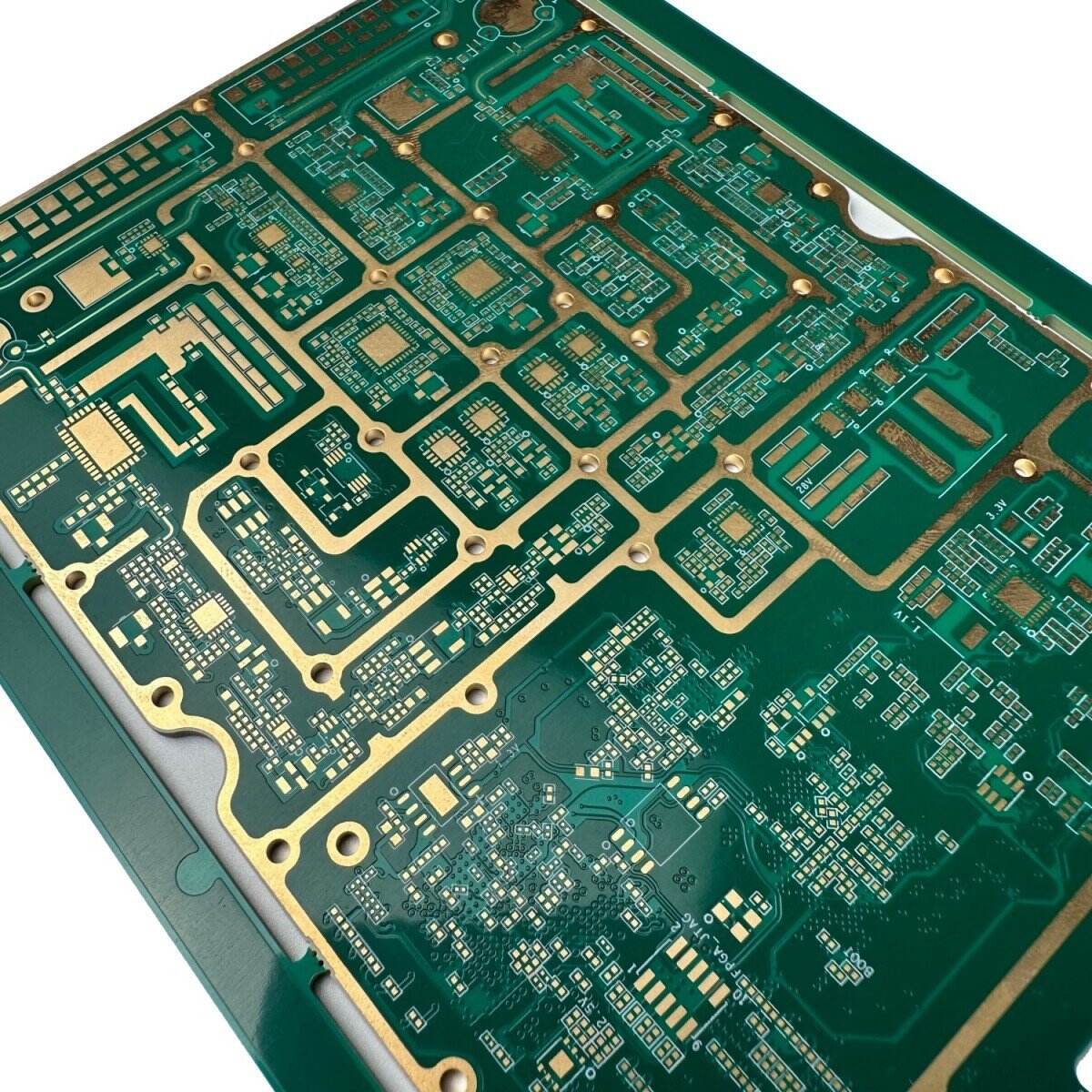

We have been making PCB for more than 20 years, and we have accumulated hundreds of project experience in Teflon PCB alone. Whether it is sample proofing or mass production, we can handle it very well:

1. Strict quality control: From DFM manufacturability assessment in the design stage to electrical testing (E-test), automatic optical inspection (AOI), BGA X-ray inspection in production, every step is indispensable to ensure zero defects in the boards shipped out of the factory;

2. No minimum order quantity: Even if you only need a few samples for testing, we will accept it and give you a free quotation;

3. Complete qualifications: Passed ISO9001 quality management system certification and UL safety certification, the whole process from materials to production is guaranteed.

If your device is in need of a high-frequency stable and extreme environment resistant circuit board, why not talk about your needs - we can recommend the most suitable Teflon PCB solution according to your specific scenario to help you maximize the performance of your equipment.