Aluminum PCB is a PCB made of aluminum, known as Metal Core Printed Circuit Board (MCPCB), which plays an important role in the circuit board family.

A thin layer of thermally conductive and electrically insulating material is usually bonded to the surface of the aluminum PCB, so it has significant thermal and electrical conductivity.

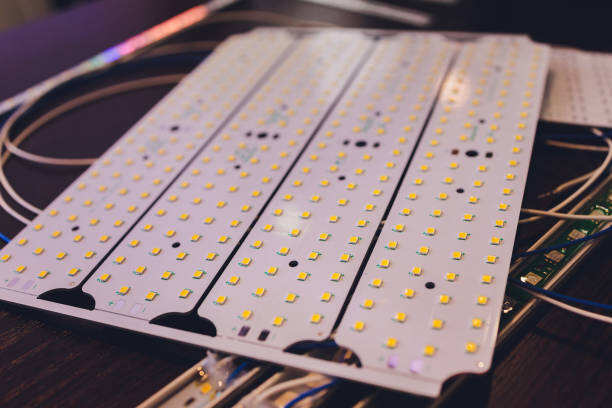

For this reason, aluminum PCBs are widely used in areas that require heat generation, such as automotive electronic equipment, high-power LED lighting, and other high-heat devices.

Aluminum-based circuit boards are mainly used in industries that require thermal conductivity. According to different expectations, the following three types of aluminum substrates can generally be selected:

A single-sided aluminum substrate is composed of a layer of metal aluminum plate as the substrate, and a layer of conductive copper is bonded on one side of the board. Although the single-sided aluminum substrate is simple in design, it is widely used in markets with high requirements for heat dissipation, such as LED lighting, automotive electronics, power supplies, etc.

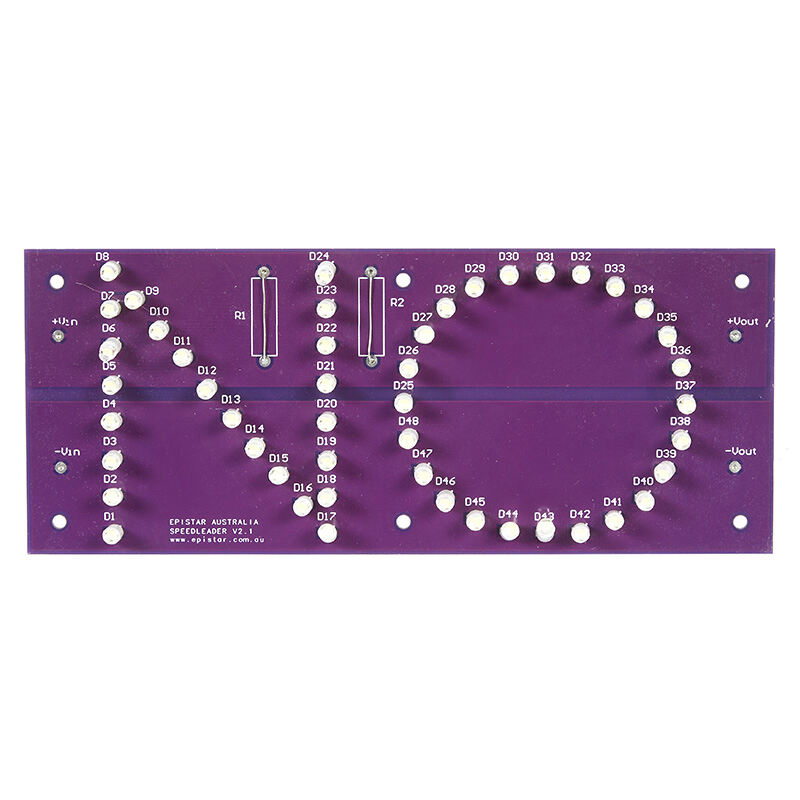

A double-sided aluminum substrate contains two layers of aluminum-based substrates, and both sides are covered with a copper layer. Compared with a single-sided aluminum substrate, it has higher design flexibility and functionality. Components can be installed on both sides of the board to meet the needs of higher component density and complex circuit design. It is suitable for applications that require stronger thermal performance and electrical isolation, such as power converters, motor drives, etc.

The base of metal core PCB is usually made of aluminum or copper alloy, sandwiched between an insulating layer and copper foil. Compared with traditional PCBs such as FR-4, metal core PCB has excellent thermal conductivity and heat dissipation capabilities. MCPCB is also called aluminum-clad PCB (Aluminum-clad PCB), which has three types: single-layer, double-layer and multi-layer.

In order to obtain the best thermal conductivity, the manufacturing of aluminum-based PCBs should focus on the following key steps:

First, choosing a suitable material is the first step to success. We often use 6061 and 5052 aluminum alloys because they have excellent thermal conductivity.

We need to find a material with strong thermal conductivity and good electrical insulation performance, such as polyimide or epoxy resin. Then use these materials to bond with the aluminum core.

During the manufacturing process, the thickness of the copper layer should be kept within a reasonable range, so that the finished board will have good heat dissipation and performance and electrical performance.

The conductive line is made by standard PCB etching process.

The high thermal conductivity of aluminum can quickly take away the heat of heat-generating components, thereby reducing the risk of overheating and extending the service life of the equipment.

The combination of aluminum substrate and copper circuit has the advantages of low thermal resistance and high thermal conductivity, which is suitable for high-power application scenarios.

In devices with strict requirements on light weight and small space, aluminum substrates are often the best choice because they are light and compact.

In harsh environments, aluminum substrates are also the best choice. Because aluminum-based PCBs have good mechanical strength and durability, they can continue to work in harsh environments.

Compared with liquid cooling and heat sinks, aluminum-based PCBs are more cost-effective in solving thermal needs, have higher thermal management solutions, and PCB design is simpler and easier to manufacture.

Usually, we can only manufacture single-layer aluminum substrates and double-layer aluminum substrates. Due to the limitations of the manufacturing process, multi-layer aluminum substrates are difficult to manufacture, so they cannot meet the needs of complex multi-layer designs.

Metal aluminum materials have high rigidity and low softness, and are not as flexible as polyimide or polyester substrates. Therefore, they are not suitable for applications that require repeated bending.

The thermal expansion coefficient of aluminum substrates is relatively high, which is different from some components and solder materials. The mismatch of the thermal expansion coefficients of the two can easily lead to solder joint damage or delamination, affecting overall reliability.

Compared with ordinary substrates, the metal properties of aluminum substrates require more time to consider during manufacturing and assembly, which will increase process complexity and cost.

Although aluminum substrates have significant advantages in thermal management, compared with traditional FR4 materials, aluminum-based PCBs have higher material costs, special manufacturing processes and surface treatment requirements, so the overall manufacturing cost increases.

Feature |

Capability |

| Substrate Material(16px) | 5052, 6061, 7075, thickness 1.6mm~9mm |

| Copper Thickness | 1oz~12oz (35μm~420μm) |

| Insulation Layer Thickness | 0.1mm~0.2mm (Bergquist Thermal-Clad, Larid Tlam) |

| Number of Layers | 1-8 layers |

| Minimum Line Width | 4mil~5mil(0.1mm~0.127mm) |

| Minimum Line Distance | 4mil~5mil(0.1mm~0.127mm) |

| Minimum Aperture | 0.3mm~1.0mm |

| Maximum Panel Size | 600mm×1170mm |

| Thermal Conductivity | 1.0~12.0 W/m·K |

| Surface Treatment | HASL, OSP, ENIG |

| Solder Mask Spacing | ≥ 3mil (0.075mm) |

| Solder Mask Color | White, Green, Black |

| Silkscreen Sides | As per the file |

| Screen Printing Layer Spacing | ≥0.15mm |

| Finished Product Packaging | Foam/Bubble Pad |

With the continuous development of electronic systems, aluminum-based PCBs have broad prospects. The current main research and development direction is to improve the thermal conductivity of insulating materials, thereby improving manufacturing efficiency and reducing costs. Aluminum substrates will also be used in emerging fields such as 5G, communications, the Internet of Things, and renewable energy.

PCBally is a company that has been focusing on aluminum-based PCB manufacturing since 2003, and has always insisted on providing services that meet high international standards.

Choose LHD as your aluminum-based PCB partner for the following reasons:

We implement a strict quality management system in all production processes. We have passed UL and ISO9001:2015 certification. We pay attention to details to ensure the stability of production quality and product safety, so that every customer can get a perfect product.

Aluminum substrates made in China have price advantages. We provide customers with cost-effective product solutions while ensuring quality.

PCBally systematically manages the production process. From raw material procurement to customer delivery, there are emergency plans to deal with emergencies such as material shortages, equipment failures, and transportation delays, and regular audits are conducted to ensure inventory and delivery reliability.

With more than 20 years of experience in aluminum-based PCB manufacturing, we have won the trust of more than 1,000 customers around the world, and our product quality and service standards are well-known in the industry.