As people's requirements for electronic technology are getting higher and higher, electronic technology is constantly updated and iterated. People also have higher and higher requirements for materials used in the manufacture of electronic products, such as high-frequency materials.

Rogers PCB material is a high-frequency board produced by Rogers Corporation. Compared with the traditional PCB epoxy resin board, it does not have glass fiber in the middle, but is a high-frequency material based on ceramic. When the operating frequency of the circuit board exceeds 500MHz, the range of materials available for design engineers to choose is greatly reduced.

Rogers PCB material offers excellent dielectric constant and temperature stability. Its dielectric constant and coefficient of thermal expansion closely match those of copper foil, improving upon the shortcomings of PTFE-based PCBs. It is ideal for high-speed designs, as well as commercial microwave and RF applications.

Because of its low water absorption, it can be used in high humidity environments. It is an ideal choice for the high-frequency board industry and can improve product quality from the source.

Generally speaking, Rogers high-frequency PCB can be defined as a printed circuit board with a frequency higher than 1GHz. It has extremely high requirements for precision, physical properties and technical parameters. It is commonly used in satellite systems, radio systems, communication systems, automotive anti-collision systems and other fields.

Ceramic-filled PTFE circuit materials. Models include: RO3003G2™, RO3003™, RO3203™, RO3035™, RO3006™, RO3010™, RO3210™, etc.

Composite materials based on ceramic, hydrocarbon, and thermoset polymers. Models include: TMM3, TMM4, TMM6, TMM10, TMM10i, and TMM13i.

RT/duroid® high-frequency circuit materials are composite laminates containing PTFE fillers (glass fiber or ceramic) for high-reliability, aerospace, and defense applications. Models include: RT/duroid® 5880, 5880LZ, 5870, 6002, 6202, etc.

RO4000 is an industry-leading family of ceramic-filled hydrocarbon laminates and prepregs. Models include: RO4003C, RO4350b, RO4533, RO4534, RO4535, RO4360G2, RO4830, RO4835T, RO4725JXR, and RO4730G3.

1. Low water absorption

Rogers PCB substrate has low water absorption, which can effectively avoid changes in dielectric constant and dielectric loss in a humid environment.

2. Thermal expansion coefficient matching

The thermal expansion coefficients of Rogers PCB substrate and copper foil should be consistent to avoid thermal expansion causing copper foil to fall off.

3. Stable and low dielectric constant

The smaller the dielectric constant Dk, the better, and the transmission speed is inversely proportional to its square root. A larger Dk will cause signal transmission delay.

4. Low dielectric loss

The smaller the dielectric loss Df, the better the signal transmission quality and the smaller the signal loss.

At present, the international 5G deployment is accelerating. Traditional 3G/4G base stations use BBU, RRU and antenna feeder system architecture. With high-frequency signal transmission, the loss will naturally increase. The integrated RRU+antenna architecture can reduce feeder loss and improve efficiency. Therefore, the high integration allows more scattered components to be replaced by PCB boards, thereby improving PCB utilization.

1. High-frequency bandwidth is large and has stronger information carrying capacity.

2. Low-frequency resources have been occupied by previous generations of communication technologies;

Electromagnetic waves are more susceptible to attenuation in high-frequency bands, and the losses of the transmitter and transmission components must be controlled. Therefore, the carrier material needs to be upgraded from ordinary boards to high-frequency boards (such as Rogers PCB RO4350). For example, the FPC flexible circuit board originally made of PI material has gradually been replaced by LCP material with lower Dk and Df. For example, Apple has applied LCP to the iPhone X antenna.

The base station part also needs to use PCBs made of high-frequency materials such as Rogers RO4350. The mainstream solutions include hydrocarbon PCB or PTFE, which cost 1.5 to 3 times more than ordinary boards. The use of high-frequency materials in 5G medium-frequency and high-frequency AAU boards has increased significantly, and the value of each board has also increased accordingly.

Usually, we can only manufacture single-layer aluminum substrates and double-layer aluminum substrates. Due to the limitations of the manufacturing process, multi-layer aluminum substrates are difficult to manufacture, so they cannot meet the needs of complex multi-layer designs.

Metal aluminum materials have high rigidity and low softness, and are not as flexible as polyimide or polyester substrates. Therefore, they are not suitable for applications that require repeated bending.

The thermal expansion coefficient of aluminum substrates is relatively high, which is different from some components and solder materials. The mismatch of the thermal expansion coefficients of the two can easily lead to solder joint damage or delamination, affecting overall reliability.

Compared with ordinary substrates, the metal properties of aluminum substrates require more time to consider during manufacturing and assembly, which will increase process complexity and cost.

Although aluminum substrates have significant advantages in thermal management, compared with traditional FR4 materials, aluminum-based PCBs have higher material costs, special manufacturing processes and surface treatment requirements, so the overall manufacturing cost increases.

Rogers PCB is a special board with high technical threshold, difficult operation and high cost in rapid prototyping. Therefore, many PCB small batch prototyping factories are unwilling to produce due to small orders or complex processes.

Rogers RO4350B material is convenient for RF engineers to design network matching, transmission line impedance control, etc. It has low dielectric loss and obvious advantages in high-frequency applications. The dielectric constant is extremely stable in a wide frequency range, with a design value of 3.66, which is suitable for broadband applications.

Rogers RO4003 material can be processed with conventional nylon brushes and does not require special treatment before electroless copper plating. Its high TG resin system (280°C+) is not prone to discoloration during drilling. If stains are present, they can be cleaned with CF4/O2 plasma or dual potassium permanganate process.

RO3003 is a ceramic-filled PTFE composite material suitable for microwave and RF applications, with a very stable dielectric constant over the entire temperature range and a loss factor of only 0.0013 at 10GHz.

The baking requirements of RO4000 are comparable to epoxy glass, and no special treatment is required under normal conditions, but attention should be paid to the risk of fire when using high-temperature equipment such as infrared reflow soldering.

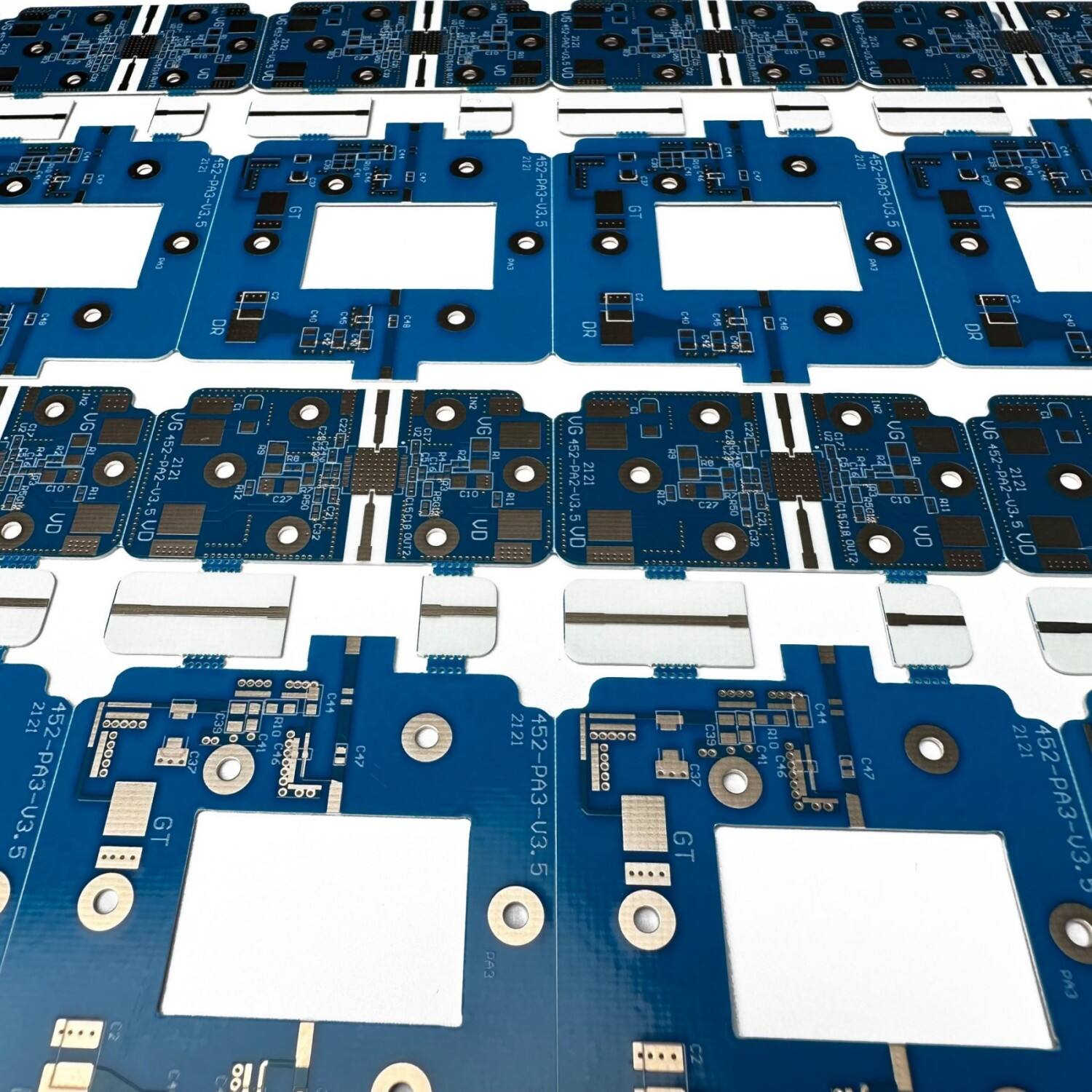

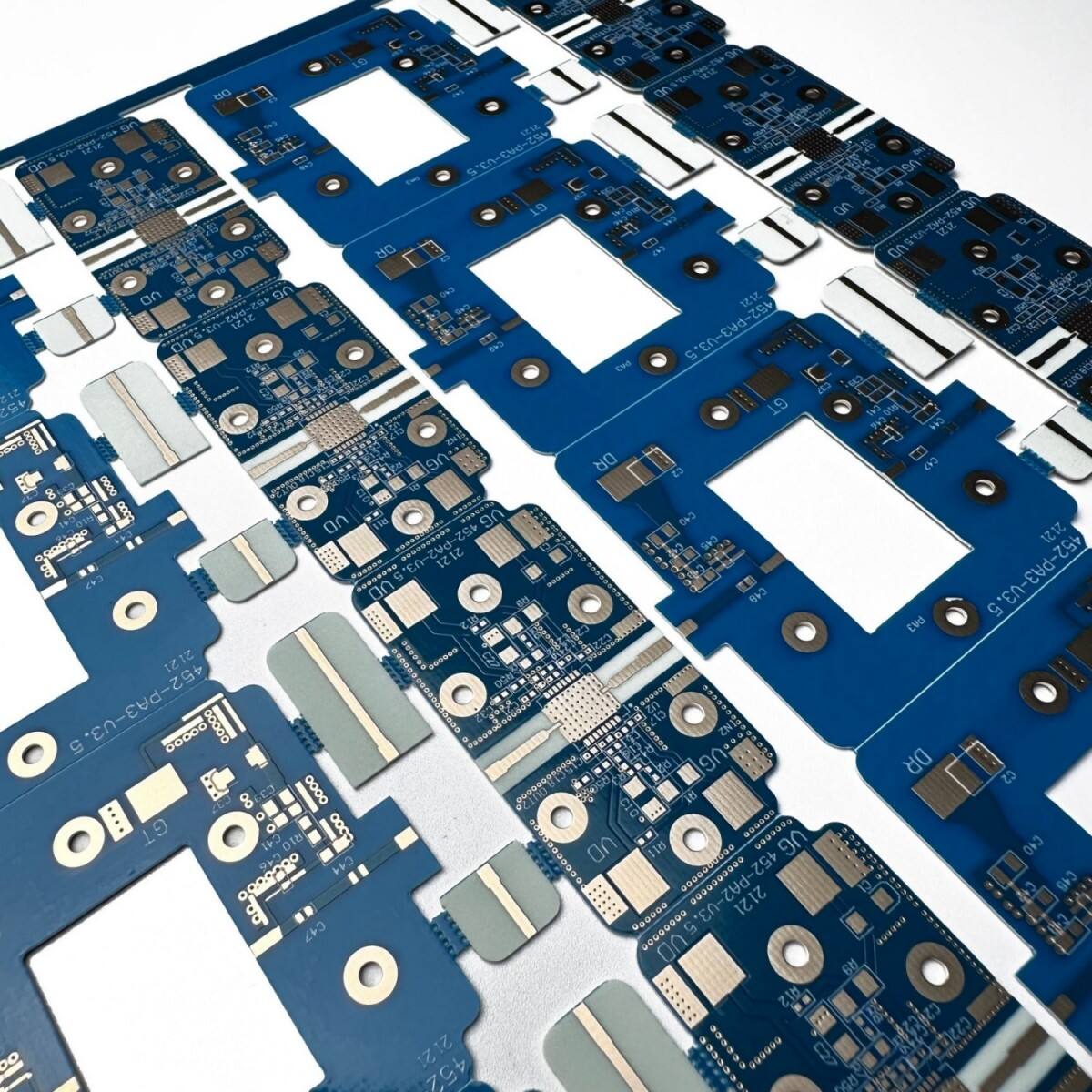

With our professional PCB manufacturing capabilities and high-quality services, PCBally has won high trust and praise from customers with excellent one-stop service.

1.PCBally is one of the best Rogers PCB manufacturers in China. We have professional production facilities and fully automated equipment, and can independently complete all processing procedures.

2.At PCBally, we can provide a variety of Rogers PCB materials, such as: Rogers 4003 PCB, Rogers 4350 PCB, Rogers 5880 PCB, RO3003 PCB, RO6002 PCB, Rogers FR4 PCB, TTM10 PCB, Rogers Ceramic PCB, Rogers PTFE PCB, etc.

3.PCBally has accumulated rich management and production experience in the past 20 years of development, and has always adhered to the honest and responsible work attitude, as well as the pursuit of quality and sustainable management management philosophy.

4. As a trusted partner, we offer excellent service and are able to resolve any issues during the Rogers PCB fabrication process. Finally, we provide ongoing after-sales service.

5. We are committed to working with our customers with high-quality products, strong technical capabilities, reasonable prices, and efficient service. If you have any Rogers PCB needs, please feel free to contact us.