In the fields of electronic manufacturing and repair, the quality of circuit board soldering directly determines product performance and lifespan. At pcbally, we’ve witnessed firsthand how subpar solder choices lead to costly rework in PCB manufacturing—reinforcing just how critical this decision is. Whether you’re a DIY electronics enthusiast or a professional in PCB manufacturing, choosing the most suitable solder is the first line of defense against cold joints and false soldering, ensuring reliable electrical connections, which can mean the difference between a flawless, reliable electronic device and one plagued by weak solder joints and costly failures.

Based on these understanding, and to address the commonly faced complexity of selection in practical work, pcbally has transformed the experience accumulated in this field into this detailed selection guide. This article will systematically cover all aspects of circuit board solder. Here you’ll find everything you need to know about soldering circuit boards, from the basics of what solder is, to the 8 best solders for circuit projects, to choosing the ideal solder for your next assembly, providing you with a practical reference manual. We’ll explore every relevant solder type—lead-based, lead-free, silver, rosin core, no-clean, and more—while equipping you with practical tips and expert advice. If you’re looking for the ultimate guide to choosing the right solder for your next circuit board project, look no further!

Solder is far more than just "glue" in Printed Circuit Board Assembly (PCBA). It bears the dual mission of creating electrical interconnections and mechanical bonds. pcbally's quality control processes reveal that improper solder choice—whether in alloy composition, flux type, or application amount—easily leads to issues like cold solder joints, solder bridges, or unreliable connections, potentially causing complete product failure. Beyond immediate failure, suboptimal solder can lead to latent defects—joints that pass initial testing but fail prematurely in the field due to increased electrical resistance or susceptibility to thermal fatigue and vibration. Therefore, understanding and correctly selecting solder is not only a fundamental skill in electronic engineering but also an investment in the long-term reliability and reputation of your product.

Solder is a low-melting-point metal alloy used to join electronic components to board pads by melting, forming a solid solder joint upon cooling. Its key characteristic is a melting point lower than the metals being joined (like copper), enabling low-temperature connection.

Solder alloys for electronics are typically a mix of tin and lead or tin with silver and copper (lead-free solder). Different element ratios give the solder unique flow properties, strength, and conductivity. For instance, the eutectic 63/37 tin-lead ratio has a distinct melting point, solidifying instantly, which simplifies process control. In contrast, non-eutectic alloys like 60/40 have a plastic range, making them more susceptible to disturbances during cooling.

During soldering, molten solder, aided by flux, fills the microscopic gaps between component leads and copper pads. Upon cooling and solidification, it achieves both electrical conduction and mechanical anchoring. The flux here also plays a critical role by chemically cleaning the surfaces. This allows the molten solder to 'wet' them effectively, meaning it spreads evenly and forms a continuous interface rather than beading up

Choosing the best solder for circuit boards starts by understanding solder types. While there are many specialty options, the most important distinction is between lead-based and lead-free solder. You'll often see references to the two types of solder:

Based on cleaning requirements and process, solder can be further categorized:

· Rosin Core Solder: It offers high versatility and activity. Although the residue is typically insulating, it is sticky and hygroscopic, often requiring cleaning with isopropyl alcohol for long-term reliability or aesthetic reasons.

· No-Clean Solder: Minimal, low-corrosivity residue, suitable for mass Surface Mount Technology (SMT) production.

·Water-Soluble Flux Solder: Residue can be removed with water, meeting extremely high cleanliness requirements like in medical or military applications. This flux is very active but also highly corrosive if not removed completely and promptly after soldering.

Solder Type |

Main Alloy |

Typical Application |

Key Benefits |

Tin-Lead (SnPb) |

60/40, 63/37 |

Repair, legacy, audiophile |

Easy to use, shiny&reliable joints |

Lead-Free (SAC305) |

SnAgCu |

All modern PCBs, RoHS |

Eco-friendly, compliant, good strength |

Silver Solder |

SnAg, SnAgCu |

High-end, vibration/thermal cycling |

High conductivity, thermal fatigue resistance, mechanical strength |

Rosin Core |

Varies |

General electronics, repair |

Self-fluxing, cleaner joints |

No-Clean Solder |

Varies |

Production, where cleaning is impractical |

Minimal residue, good for SMT |

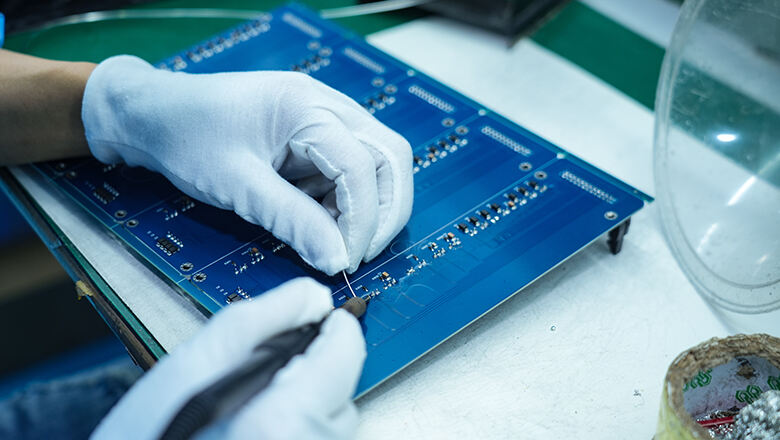

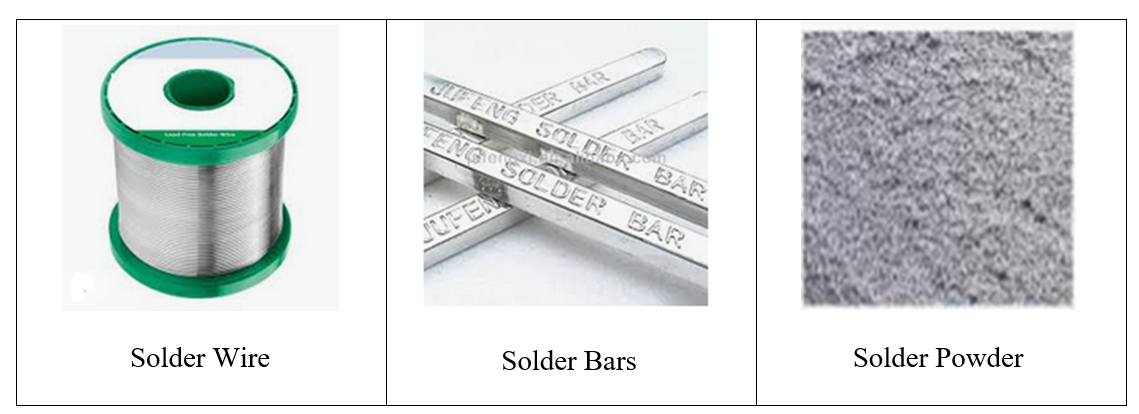

The physical form of solder directly affects the operation process and efficiency. Selecting the wrong form can lead to defects, inefficiency, and increased cost, regardless of the alloy's quality.

Your technique, project scope, and circuit complexity dictate the right solder form. Solder wire allows precise, manual control—ideal for R&D, prototyping, repair, or low-volume production. Solder paste is applied for anything involving reflow soldering or precise SMD work. Solder bars are for industrial-scale assembly lines. At pcbally, we help clients select the optimal form based on their production volume, component mix, and quality requirements, ensuring efficiency and cost-effectiveness.

No comprehensive guide to the best solder for circuit boards would be complete without discussing flux—a crucial ingredient in strong, clean solder joints.

Flux removes oxides from metal surfaces before and during soldering. Without flux, solder won’t adhere properly, resulting in weak solder joints or open circuits.

· Rosin Core Solder:

Contains natural resin from pine trees; highly effective at removing oxidation.

Leaves a residue that can be cleaned off with isopropyl alcohol for long-term reliability or aesthetic reasons.

Traditional and popular for repair, audio, and hobby projects.

· No-Clean Solder:

Leaves little to no residue—any remaining can typically be left on the board. It's critical to verify that the residue is truly non-corrosive and non-conductive under your product's specific operating conditions (e.g., high humidity).

Ideal for mass production, SMT and consumer electronics, simplifying post-process steps.

· Water-Soluble Flux:

Thoroughly cleaned with water, meets the highest cleanliness standards, but requires prompt aqueous cleaning. This flux is very active but also highly corrosive if not removed completely and promptly after soldering.

It often used for medical, military, or aerospace electronics where any residue is unacceptable.

Selecting between lead-based and lead-free solder is perhaps the most critical and confusing decision for anyone aiming to select the best solder for their next circuit board project. The choice is often dictated by regulation, but understanding the technical implications is vital for success.

Feature |

Lead-Based (Tin-Lead) |

Lead-Free (SAC, SnAgCu, etc.) |

Melting Point |

183–190°C |

217–221°C |

RoHS Compliant |

No |

Yes |

Electrical Conductivity |

Excellent |

Very Good |

User-Friendliness |

Very Easy |

Moderate |

Health/Environment |

Hazardous |

Safer |

Joint Appearance |

Shiny |

Slightly Dull |

Typical Use |

Repairs, legacy, audio |

New projects, mass production |

No ultimate guide is complete without brand-specific advice! Here are our top 8 best solders for circuit boards, used by professionals worldwide:

Brand |

Solder Type/Form |

Best For |

Kester 44 Rosin Core Solder |

Tin-Lead, Rosin Core, Wire |

Legacy, repair, audio, easy shiny joints |

Alpha Fry AT-31604 |

Tin-Lead, Rosin Core, Wire |

Beginner DIY, low-cost, general purpose |

MG Chemicals 63/37 |

Tin-Lead, No-Clean, Wire |

Repair, no residue, reliable results |

WYCTIN 60/40 Solder Wire |

Tin-Lead, Rosin Core, Wire |

Everyday prototyping, education |

SRA Soldering Products Rosin Core Solder |

Tin-Lead, Rosin Core, Wire |

General PCB work, consistent results |

Cardas Soldering Wire |

Silver Solder, Rosin Core, Wire |

Audiophile, high-frequency, precision audio |

Harris Stay-Brite Silver Solder |

Silver Alloy, Wire/Bar |

Automotive, vibration, high-end circuits |

Worthington Solder Wire |

Tin-Lead, Rosin Core, Wire |

Budget, prototyping, schools |

Make an informed choice by comprehensively evaluating the following points. This checklist serves as a systematic approach to solder selection:

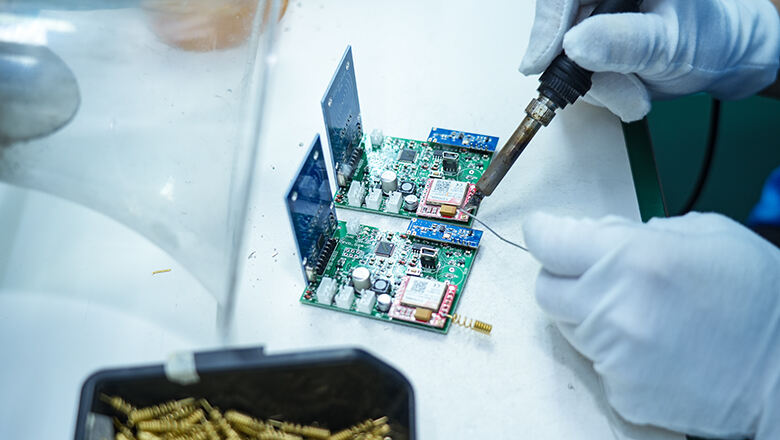

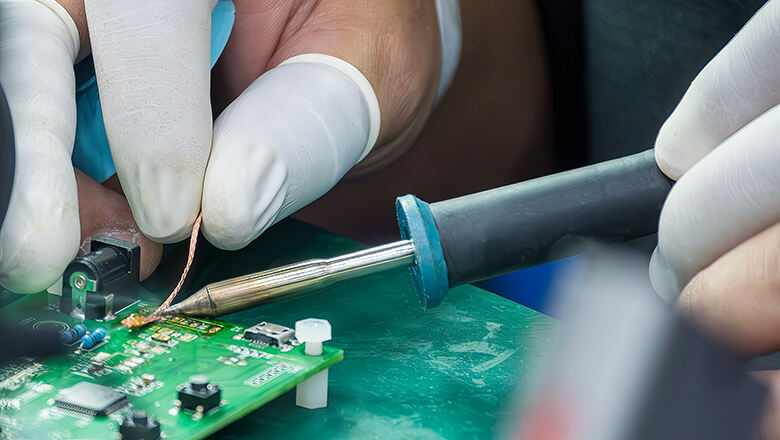

Workspace Preparation:

Use an anti-static mat and good lighting.

Power up a temperature-controlled soldering iron.

Component and Pad Cleaning:

Remove oxidation and excess solder using isopropyl alcohol and, if needed, solder wick or a solder sucker.

Component Placement:

Angle to fit the circuit; ensure leads fit the circuit board holes properly.

Applying Solder:

Heat pad and component with the iron, then feed solder wire or apply solder paste.

Solder should flow smoothly and wick across both surfaces.

Use the proper amount of solder applied—too little results in weak solder joints, too much creates excess solder or bridges.

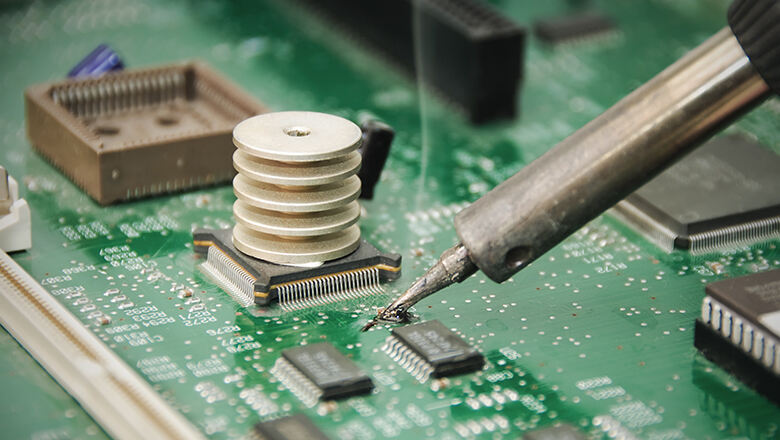

Solder Inspection:

A good solder joint should appear shiny and concave, without icicles or solder balls.

Inspect with a magnifying glass or microscope for reliable solder joints.

Post-Solder Cleaning:

Clean solder residue with isopropyl alcohol if needed, especially for rosin or water-soluble flux.

Problem |

Likely Cause |

Solution |

Cold solder joint |

Low temp, dirty pad, rushed soldering |

Clean pad, raise temp, re-solder |

Solder bridge |

Excess solder applied, too thick solder |

Use solder wick/sucker, apply less |

Weak joint |

Moving part, not enough solder |

Secure component, reheat/rewet joint |

Excess flux residue |

High-activity or uncleaned flux |

Clean with isopropyl alcohol |

Dull joint |

Cheap solder, wrong temperature |

Use high-quality solder, control iron |

Recycle old solder, circuit boards, and manufacturing waste responsibly. Even lead-free solders have environmental impacts, so always minimize waste and store chemicals safely.

In electronics manufacturing, solder selection and application is a discipline combining materials science, process technology, practical experience, and respect for environment. The correct choice not only enables reliable electrical connections but is also foundational to the long-term stable operation of the product—whether it’s an innovative IoT board, a vintage amplifier, or a next-generation automotive controller.

As your trusted manufacturing partner, pcbally understands this deeply. And this comprehensive guide is your ultimate guide to choosing and using the right solder for your circuit:

With this knowledge, you’re ready to undertake your next circuit board project—confident that your electrical connections will be strong and your assemblies will stand the test of time. If you require professional support in solder selection or any PCB manufacturing, pcbally's technical team is always ready to assist you. With this knowledge, you can confidently tackle your next circuit board project.

Q: How do I select the best solder for my next circuit board project?

A: Start by determining if you need RoHS (lead-free solder), the type of components (SMD vs through-hole), and expected loads (audio, automotive, high-frequency). Then, choose the solder type, form (wire, paste, bar), flux, and diameter that best fit your circuit.

Q: Is silver solder always the best solder for circuit boards?

A: Silver solder offers strength and superior conductivity, useful for high-reliability, high-frequency, or audiophile circuits, but may be overkill for basic projects.

Q: Can I mix solder types (lead-based and lead-free solder) on the same board?

A: It’s best not to—mixing alloys can result in unpredictable melting points and joint qualities. Use one consistent solder type per board.

Q: Does solder wire diameter matter?

A: Yes! Thicker solder wire is for big components, power connections, or grounds; thin solder wire allows for precision in SMD and small-joint work.

Q: Do I always need to clean flux residue?

A: If you use rosin core solder, yes—clean with isopropyl alcohol. With no-clean solder, only clean in high-reliability or visual-critical areas.

Q: What about cleaning or reworking a soldered circuit?

A: Always use a specialized tool like a solder sucker or good-quality solder wick to remove unwanted or excess solder before reapplying solder.

Q: How long does quality solder last in storage?

A: Solder wire (stored dry and sealed) lasts for years; solder paste should be used within manufacturer’s date (usually 6–12 months refrigerated).