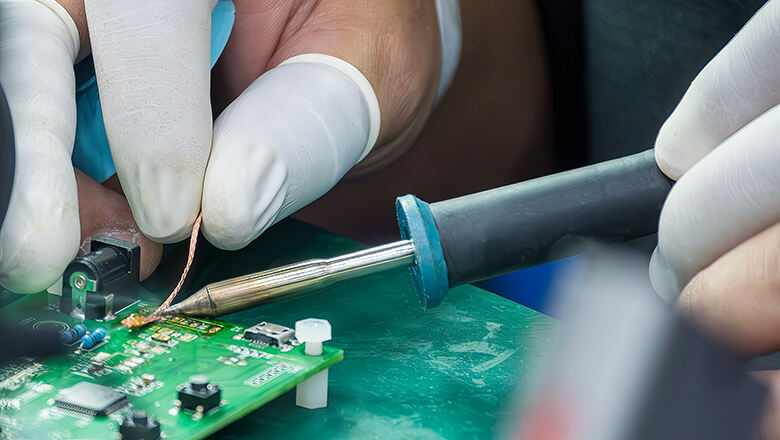

בתחומי הייצור והתיקון האלקטרוניים, איכות הלחמת לוחות המעגלים קובעת ישירות את הביצועים ואת אורך החיים של המוצר. ב-pcbally, חווינו על בשרנו כיצד בחירות לא טובות של לחם מובילות להוצאות כבדות של עבודה חוזרת בייצור PCB – מה שמדגיש עד כמה חשוב ההחלטה הזו. בין אם אתם חובבי אלקטרוניקה שעוסקים בעבודה עצמית או אנשי מקצוע בתחום ייצור לוחות מעגלים, בחירת הלحام המתאים ביותר היא הקו הראשון של ההגנה מפני חיבורים קרים וחיבורים כוזבים, ומבטיחה חיבורים חשמליים אמינים, מה שיכול להפוך ניסור בין מכשיר אלקטרוני מושלם ואמין לבין מכשיר הסובל מחיבורי לحام חלשים וכשלים יקרים.

בהתבסס על הבנות אלו, וכדי להתמודד עם המורכבות הנפוצה של בחירה בעבודה מעשית, pcbally הפכה את הניסיון שנצבר בתחום זה למדריך בחירה מפורט זה. מאמר זה יכסה באופן שיטתי את כל ההיבטים של הלחמת מעגלים. כאן תמצאו את כל מה שאתם צריכים לדעת על הלחמת מעגלים, החל מהיסודות של מהי הלחמה, דרך 8 חומרי ההלחמה הטובים ביותר לפרויקטים של מעגלים, ועד לבחירת הלחמה האידיאלית להרכבה הבאה שלכם, ויספק לכם מדריך עיון מעשי. נחקור כל סוג הלחמה רלוונטי - מבוסס עופרת, ללא עופרת, כסף, ליבת רוזין, ללא ניקוי ועוד - תוך כדי ציידתכם בטיפים מעשיים ועצות מומחים. אם אתם מחפשים את המדריך האולטימטיבי לבחירת הלחמה המתאימה לפרויקט המעגלים הבא שלכם, אל תחפשו רחוק יותר!

לחם חימר הוא הרבה יותר מאשר רק 'דבוק' בהרכבת לוחות מעגלים מודפסים (PCBA). עליו מוטלת המשימה הכפולה של יצירת חיבורים חשמליים וקשרים מכניים. תהליכי בקרת איכות של pcbally מראים שבחר לא נכון בלחם חימר – בין אם בהרכב הסגסוגת, סוג הזרס או כמות היישום – עלול בקלות להוביל לבעיות כמו חיבורי לחם קרים, גשרי לחם או חיבורים לא אמינים, שעשויים לגרום לכשל מלא של המוצר. מעבר לכשל מיידי, לחם חימר לא אופטימלי עלול להוביל למפגעים חבויים – חיבורים שעוברים את הבדיקה הראשונית אך נכשלים מראש בשדה עקב עלייה בהתנגדות חשמלית או רגישות לריסוק תרמי ורטט. לכן, ההבנה והבחירה הנכונה של לחם חימר היא לא רק כישרון בסיסי בהנדסת אלקטרוניקה, אלא גם השקעה בנوثנות ארוכת טווח ובמוניטין של המוצר שלך.

סOLDER הוא סגסוגת מתכת עם נקודת התכה נמוכה, המשמש לחיבור רכיבים אלקטרוניים ללוחות באמצעות התכה, ויצירת חיבור מגבש לאחר הקירור. מאפיינו המרכזי הוא נקודת ההיתוך הנמוכה יותר מהמתכות שמחוברים (כגון נחושת), מה שמאפשר חיבור בטמפרטורות נמוכות.

סגסוגות סOLDER לאלקטרוניקה הן בדרך כלל ערבוב של станן ועופרת או stanן עם כסף ונחושת (סOLDER ללא עופרת). יחסי יסודות שונים מעניקים לסOLDER תכונות זרימה, חוזק ו מוליכות ייחודיות. למשל, יחס eutectic של 63\37 stanן-עופרת יש לו נקודת התכה מוגדרת, והוא מתגבש מיידית, מה שמקל על בקרת התהליך. לעומת זאת, סגסוגות לא eutectic כמו 60\40 יש טווח פלסטי, מה שעושה אותן רגישות יותר להפרעות במהלך הקירור.

במהלך הלحام, מלט נוזלי, בעזרת פלックス, ממלא את הפערים המיקרוסקופיים בין הרגליים של הרכיבים לבין הדסקות הנחושתיות. לאחר קירור וصلידה, הוא משיג הן מוליכות חשמלית והן עגינה מכנית. הפלקס ממלא כאן תפקיד חשוב גם כן, על ידי ניקוי כימי של המשטחים. זה מאפשר למלט הנוזלי להרטיב אותם בצורה יעילה, כלומר להתפשט באופן אחיד וליצור ממשק רציף במקום לצרור.

בחירת המלט הטוב ביותר ללוחות מעגלים מתחילה בהבנת סוגי המלט. למרות שישנן מגוון אפשרויות מיוחדות, ההבחנה החשובה ביותר היא בין מלט מבוסס עופרת למלט ללא עופרת. לעתים קרובות תראו התייחסויות לשני סוגי המלט:

בהתבסס על דרישות ניקוי ותהליך הייצור, ניתן לסווג לחיים באופן נוסף:

· לحام ליבת רוזין: מציע גמישות והפעלה גבוהים. אף על פי שהשאריות הן בד"כ מבודדות, הן דביקות וסופגות לחות, וчастית יש צורך בנקיה בעזרת אלכוהול איזופרופיל לצורך אמינות ארוכת טווח או מסיבות אסתטיות.

· לحام No-Clean: שאריות מינימליות עם ניידות קורוזיה נמוכה, מתאים לייצור המוני של טכנולוגיית ריסוק (SMT).

· לحام פלקס מסיס במים: ניתן להסיר את השאריות באמצעות מים, כדי לעמוד בדרישות ניקיון גבוהות במיוחד, כמו ביישומים רפואיים או צבאיים. הפלקס הזה מאוד פעיל, אך גם קורוזיבי מאוד אם לא מוסר לחלוטין ובצורה מיידית לאחר הלحام.

סוג לحام |

Сплав 메인 |

יישום טיפוסי |

היתרונות העיקריים |

Tin-Lead (SnPb) |

60/40, 63/37 |

תיקון, ירושה, חובבי שמע |

קל לשימוש, חיבורים מבריקים ואמינים |

ללא עופרת (SAC305) |

SnAgCu |

כל לוחות PCB מודרניים, RoHS |

ידידותי לסביבה, תואם, חוזק טוב |

סלבר לחם |

SnAg, SnAgCu |

איכות גבוהה, רטט/מחזורי חום |

מוליכות גבוהה, עמידות בפני עייפות תרמית ובעלות מכאנית |

ליבת רוזין |

משתנה |

אלקטרוניקה כללית, תיקון |

עצמי זריה, מחברים נקיים יותר |

לחoutu בלי שטיפה |

משתנה |

ייצור, שבו שטיפה אינה מעשית |

שארית מינימלית, מתאים ל-SMT |

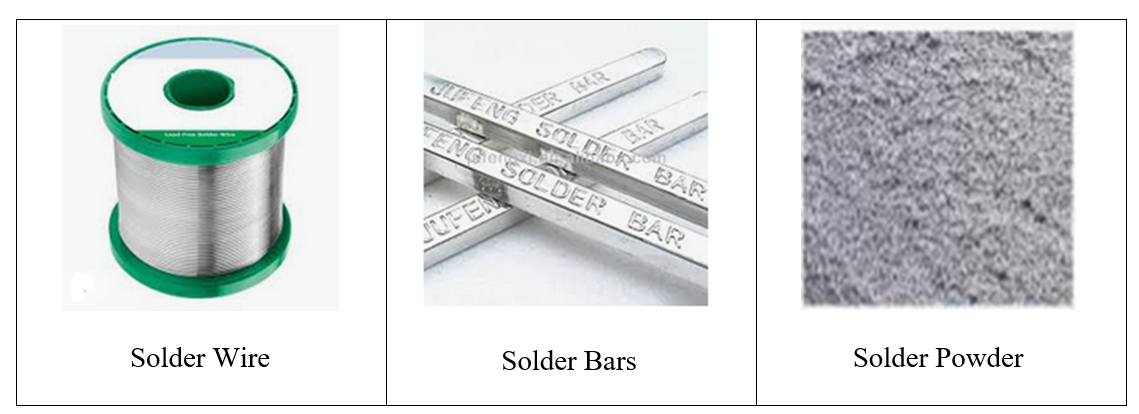

הצורה הפיזית של הלחoutu משפיעה ישירות על תהליך ההפעלה והיעילות. בחירה בצורת לא מתאימה עלולה להוביל לפגמים, יעילות נמוכה ו העלויות גבוהות יותר, ללא תלות באיכות הסגסוגת.

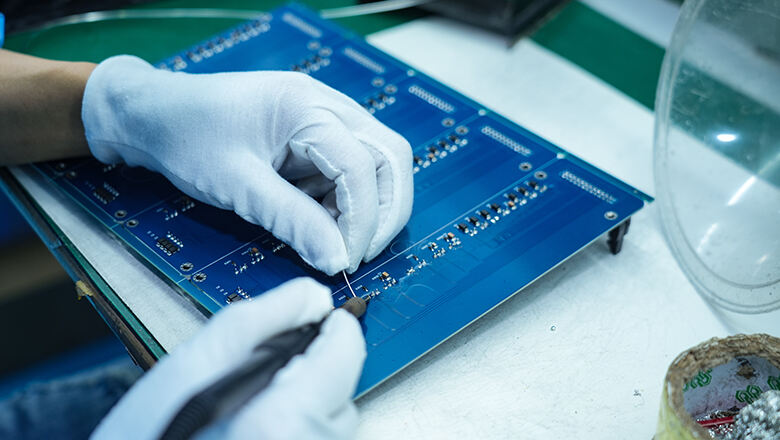

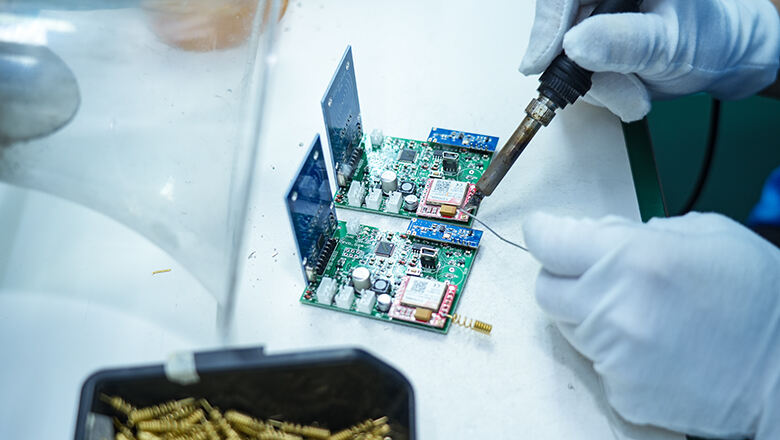

הטכניקה, היקף הפרויקט והסיבוכיות של המעגל קובעים את צורת הלחימן הנכונה. חוט לحام מאפשר שליטה מדויקת וידנית - אידיאלי ל-R&D, פיתוח פרוטו, תיקון או ייצור בכמות נמוכה. פסט הלחימן משמש בכל מה שכולל לحام ריפלו או עבודה מדויקת עם SMD. מוטות לحام מיועדים לخطوط ייצור תעשייתיים. ב-pcbally, אנו עוזרים ללקוחות לבחור את הצורה האופטימלית בהתאם לנפח הייצור, תעריב הרכיבים ודרישות איכות, ומבטיחים יעילות ויעילות עלות.

אין דרך מקיפה לבחירת הלחמה הטובה ביותר למעגלי חשמל שמושלמת ללא דיון בפלקס – מרכיב חיוני לחיבורים חזקים ונקיים.

פלקס מסיר חומרים חלויים מפני שטח המתכת לפני ובמהלך הלحام. ללא פלקס, הלחם לא ידבוק כראוי, מה שיגרום לחיבורים חלשים או לפסי conductors פתוחים.

· לحام ליבת רוזין:

מכיל רזינה טבעית מעצי אורן; יעיל במיוחד ב הסרת חימצון.

משאיר שאריות שניתן לנקות בעזרת אלכוהול איזופרופיל לצורך אמינות ארוכת טווח או סיבות אסתטיות.

שיטה קלאסית ופופולרית לתיקון, ציוד שמע והרכבת פרוייקטים חובבים.

· לحام No-Clean:

משאיר מעט מאוד שאריות – שאריות שנותרו ניתן בדרך כלל להשאיר על הלוח. חשוב לוודא שהשאריות אינן קורוזיביות ולא מוליכות בתנאי הפעלה ספציפיים של המוצר שלך (למשל, רמת לחות גבוהה).

אידיאלי לייצור המוני, SMT ואלקטרוניקה לצרכן, מפשט את שלבי העיבוד שלאחר הלحام.

· פלקס מסיס במים:

מנוקה היטב במים, עומד בדרישות הניקיון הגבוהות ביותר, אך דורש ניקוי מיידי במים. פלקס זה פעיל מאוד, אך גם קורוזיבי מאוד אם לא מוסר לחלוטין ובאופן מידי לאחר הלحام.

לרוב נעשה שימוש בו באלקטרוניקה רפואית, צבאית או תעופת-חלל, שם כל שארית אינה מתקבלת על הדעת.

בחירת בין לحام עם עופרת ללא עופרת היא אולי ההחלטה החשובה והמבולבלת ביותר לכל מי שמבקש לבחור את הלحام הטוב ביותר לפרויקט לוח המעגלים הבא שלו. הבחירה נקבעת לעיתים קרובות על ידי תקנות, אך ההבנה של ההשלכות הטכניות היא חיונית להצלחה.

תכונה |

מבוסס עופרת (בדיל-עופרת) |

ללא עופרת (SAC, SnAgCu, וכו') |

נקודת התהודה |

183–190°C |

217–221°C |

תואם RoHS |

לא |

כן |

תדמית חשמלית |

מְעוּלֶה |

מאוד טוב |

ידידותיות למשתמש |

מאוד קלה |

לְמַתֵן |

בריאות/סביבה |

סוכן מסוכן |

בטוח יותר. |

מראה החיבור |

נוצץ |

עדין מעט |

שימוש טיפוסי |

ripairs, ירושה, אודיו |

פרויקטים חדשים, ייצור המוני |

אין מדריך מקיף בלי עצות שמבוססות על מותג! להלן שמונת הלחטמים הטובים ביותר שלנו ללוחות מעגלים, שנמצאים בשימוש עולמי של אנשי מקצוע:

מותג |

סוג/צורה של לחטם |

הכי מתאים עבור |

Kester 44 Rosin Core Solder |

עופרת-בדיל, ליבת רוזין, חוט |

שימוש בתקופות קודמות, תיקון, אודיו, חיבורים קלים ובריקים |

Alpha Fry AT-31604 |

עופרת-בדיל, ליבת רוזין, חוט |

חובב מתחיל, עלות נמוכה, מטרה כללית |

MG Chemicals 63/37 |

עופרת טינט-ליד, ללא ניקוי, תיל |

תיקון, ללא שאריות, תוצאות אמינות |

תיל לחימצון WYCTIN 60/40 |

עופרת-בדיל, ליבת רוזין, חוט |

אבטיפוסים יומיומיים, חינוך |

מוצרי להטשה SRA - תיל להטשה עם ליבה רוזינית |

עופרת-בדיל, ליבת רוזין, חוט |

עבודות PCB כלליות, תוצאות עקביות |

תיל להטשה Cardas |

להטשה אג'דית, ליבה רוזינית, תיל |

מאויבי מוזיקה, תדר גבוה, אודיו מדויק |

להטשה אג'דית Harris Stay-Brite |

ספוג ארגמן, חוט/מוט |

רכב, רטט, מעגלים מתקדמים |

חוט הלחמה של וורת'ינגטון |

עופרת-בדיל, ליבת רוזין, חוט |

תקציב, פיתוח פרוטואוטייפ, בתי ספר |

примו החלטה מושכלת על ידי הערכת נקודות אלו באופן מקיף. רשימת בדיקה זו מהווה גישה שיטתית לבחירת חומר הלحام:

הכנת מקום העבודה:

השתמשו בשטיח נוגד סטטי ואור טוב.

הדליקו מתקן הלחמה עם בקרת טמפרטורה.

ניקוי רכיבים ופדים:

הסרת חימצון וצמד מיותר באמצעות אלכוהול איזופרופיל, ובמידת הצורך - פיתיית צמד או משאבת צמד.

הצבת רכיבים:

היווכחו שהתאמת הזווית מתאימה למעגל; ודאו שהרגליים מתאימות לתוך החורים בלוח המעגלים.

החלת צמד:

חמם את הלוח והרכיב בעזרת הפטיש, ואז הזן תיל להלחמה או חומר להטחה.

החומר должен לזרום בצורה חלקה ולפזר את עצמו על שני המשטחים.

השתמש בכמות המתאימה של חומר להטחה – כמות קטנה מדי תוביל לחיבורים חלשים, וכמות גדולה מדי תיצור עודף חומר או גשרים.

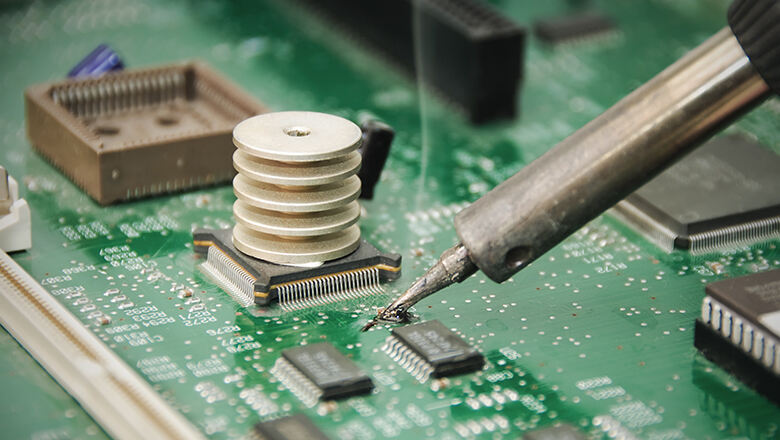

בדיקת הלحמה:

חיבור להטחה טוב צריך להראות מבריק וקעור, ללא קיסנונים או כדורי להטחה.

בדוק באמצעות זכוכית מגדלת או מיקרוסקופ כדי לוודא חיבורי להטחה אמינים.

ניקוי לאחר להטחה:

נקה שאריות להטחה בעזרת אלכוהול איזופרופילי אם יש צורך, במיוחד במקרה של רוזין או פלקס מסיס במים.

בעיה |

סיבת התקלה |

פִּתָרוֹן |

חיבור לحام קר |

טמפרטורה נמוכה, פד מלוכלך, לحام מהיר מדי |

נקה את הפד, הגב את הטמפרטורה, חזר על הלحام |

גשר לحام |

שימוש במיותר בלحام, לحام עבה מדי |

השתמש בפיתיון לحام/מוצץ, הכן פחות |

חיבור חלש |

חלק נע, לא מספיק סOLDER |

רכיב מאובטח, חימום מחדש/הרטיה מחדש של החיבור |

שאריות זרחן מופרזות |

זרחן בפעילות גבוהה או לא נקי |

ניקוי בעזרת אלכוהול איזופרופיל |

חיבור עמום |

סOLDER זול, טמפרטורה לא נכונה |

שימוש בסOLDER איכותי, שיקוע טמפרטורת הצלחת |

recycling של טיטanium ישן, שלטי מעגלים ופסולת ייצור באופן אחראי. גם טיטanium ללא עופרת משפיעים על הסביבה, ולכן יש לצמצם תמיד את הפסולת ולשמור חומרים כימיים בצורה בטוחה.

ביצור אלקטרוני, בחירת הלحام ויישומו הם תחום שמשלב מדע חומרים, טכנולוגיית תהליך, ניסיון מעשי וכבוד לסביבה. הבחירה הנכונה לא רק מאפשרת חיבורים חשמליים אמינים, אלא גם מהווית יסוד להפעלה יציבה לאורך זמן של המוצר – בין אם מדובר בלוח IoT חדשני, מגבר וינטג' או בקר לדור הבא בתחום הרכב.

כשותף המאובטח שלכם בייצור, pcbally מבינה זאת לעומק. והמדריך המקיף הזה הוא המדריך האולטימטיבי לבחירת ולשימושבלحام המתאים למעגל שלך:

עם ידע זה, אתם מוכנים לקחת על עצמכם את פרויקט לוח המעגלים הבא — בטוחים ש החיבורים החשמליים שלכם יהיו חזקים וההרכבות יחזיקו מעמד לאורך זמן. אם נדרשת תמיכה מקצועית בבחירת לחם או בכל ייצור של PCB, צוות הטכנאי של pcbally תמיד מוכן לסייע לכם. עם ידע זה, תוכלו להתמודד בביטחון עם הפרויקט הבא שלכם של לוח מעגלים.

שאלה: איך בוחרים את הלحام הטוב ביותר לפרויקט לוח המעגלים הבא?

תשובה: התחלו בקביעת האם אתם צריכים RoHS (להט חסר עופרת), סוג הרכיבים (SMD לעומת Through-hole), והעומסים הצפויים (שמע, רכב, תדר גבוה). לאחר מכן, בחרו את סוג הלحام, הצורה (חוט, משחה, מסילה), זורם והקוטר המתאימים ביותר למעגל שלכם.

שאלה: האם להט אבץ הוא תמיד הבחירה הטובה ביותר עבור לוחות מעגלים?

ת: גזירת הכסף מציעה חוזק ותDUCTיביות מעולה, מה שמועיל במעגלים בעלי אמינות גבוהה, תדר גבוה או למעגלי אודיו-פיל, אך עלולה להיות מוגזמת עבור פרוייקטים בסיסיים.

ש: האם ניתן לערבב סוגי גזירה (עם עופרת ובלי עופרת) על אותו לוח?

ת: עדיף שלא – ערבוב של יסודות יכול להוביל לנקודות התכה לא צפויות ואיכות חיבורים לא אחידה. יש להשתמש בסוג גזירה אחיד לכל לוח.

ש: האם קוטר חוט הגזירה חשוב?

ת: כן! חוט גזירה עבה מיועד לרכיבים גדולים, חיבורי כוח או קרקע; חוט גזירה דק מאפשר דיוק בעבודות SMD וחיבורים קטנים.

ש: האם תמיד צריך לנקות שאריות זרחן?

ת: אם משתמשים בגזירה עם ליבה רוזינית, כן – נקה בעזרת אלכוהול איזופרופילי. עם גזירה ללא ניקוי, נקה רק באזורים של אמינות גבוהה או חשיבות חזותית.

ש: מה לגבי ניקוי או תיקון מעגל מגוזר?

ת: השתמש תמיד בכלי מיוחד כמו משאבת גזירה או פתיל גזירה איכותי כדי להסיר גזירה לא רצויה או מיותרת לפני החזרת הגזירה.

שאלה: כמה זמן נשמר לحام איכותי באחסון?

תשובה: חוט לحام (שמור יבש וארוז) יכול להחזיק שנים; משחת לحام צריכה לשמש בתוך תקופת התפוגה של היצרן (לרוב 6–12 חודשים, בהקפאה).