The evolution of electronic devices has fundamentally transformed how we design and manufacture modern technology. Surface Mount Technology represents a revolutionary approach to assembling electronic components that has become indispensable in today's manufacturing landscape. SMT Assembly enables manufacturers to create smaller, more efficient, and highly reliable electronic products that meet the demanding requirements of contemporary applications. This advanced assembly method has replaced traditional through-hole mounting in most applications, offering superior performance characteristics and manufacturing efficiency. The precision and reliability offered by SMT Assembly have made it the cornerstone of modern electronics production.

Understanding SMT Assembly Technology

Core Principles of Surface Mount Technology

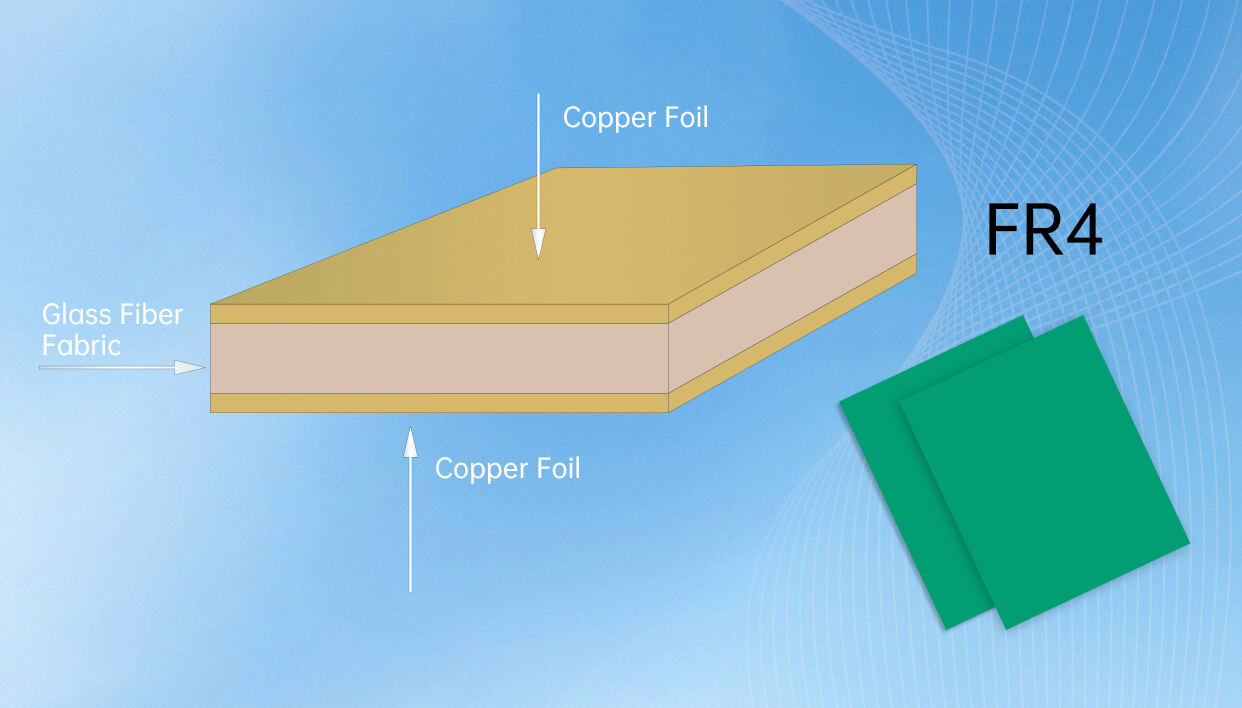

Surface Mount Technology operates on the fundamental principle of mounting electronic components directly onto the surface of printed circuit boards rather than inserting leads through holes. This approach allows for significantly higher component density and enables the creation of more compact electronic devices. The SMT Assembly process involves precise placement of components using automated equipment that can achieve positioning accuracies measured in micrometers. Components used in SMT Assembly are specifically designed with flat leads or terminations that create strong mechanical and electrical connections when properly soldered to the PCB surface.

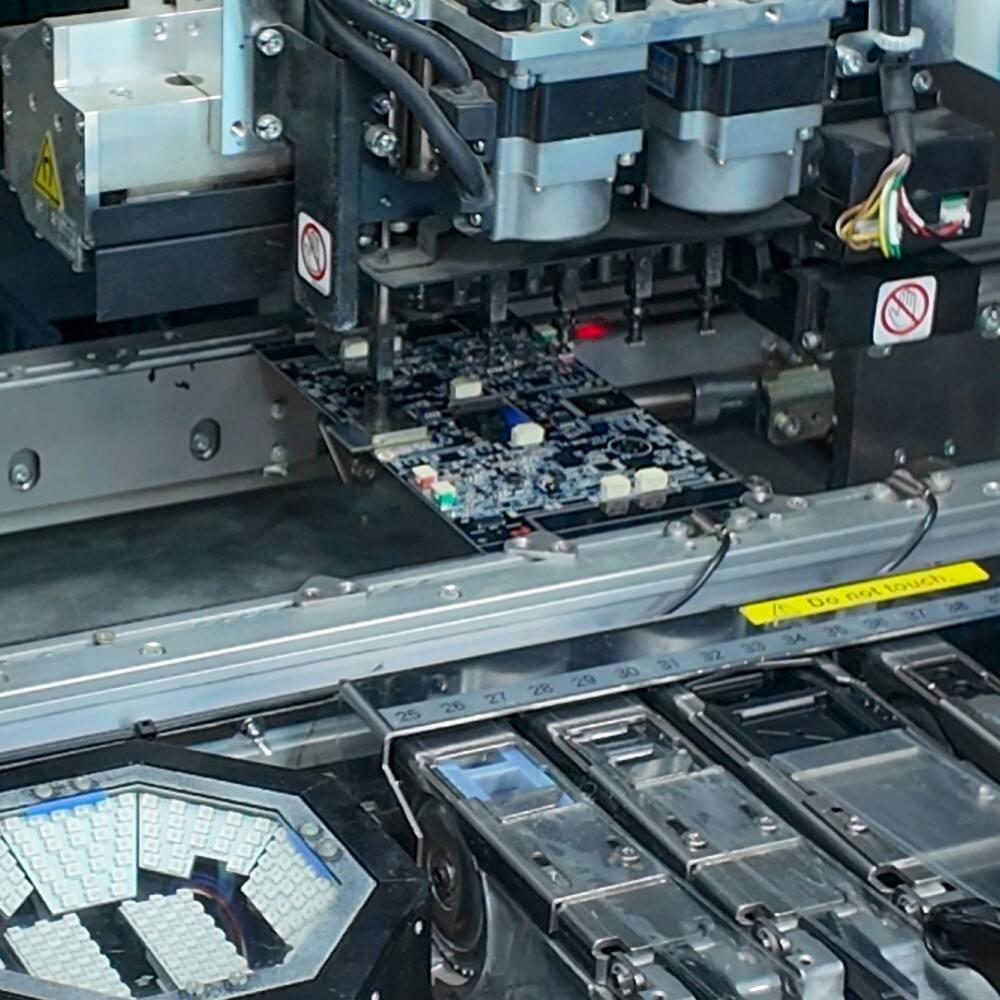

The technology relies on sophisticated pick-and-place machines that can handle thousands of components per hour with exceptional accuracy. These machines use vision systems and advanced algorithms to ensure proper component orientation and placement. SMT Assembly also incorporates reflow soldering processes that create reliable joints through controlled heating profiles. The entire process is highly automated, reducing human error and increasing production consistency while maintaining the high quality standards required for modern electronics.

Advantages Over Traditional Assembly Methods

SMT Assembly offers numerous advantages compared to traditional through-hole mounting techniques. The most significant benefit is the dramatic reduction in PCB size requirements, as surface mount components are typically much smaller than their through-hole counterparts. This size reduction directly translates to more compact final products, which is crucial in applications where space is at a premium. Additionally, SMT Assembly allows for components to be mounted on both sides of the PCB, further increasing circuit density and functionality.

The electrical performance characteristics of SMT Assembly are superior in many applications, particularly at high frequencies. The shorter lead lengths in surface mount components reduce parasitic inductance and capacitance, resulting in better signal integrity and reduced electromagnetic interference. Manufacturing efficiency is also significantly improved through SMT Assembly, as the automated nature of the process enables higher production volumes with consistent quality. The reduced material usage and simplified inventory management associated with SMT Assembly contribute to lower overall manufacturing costs.

SMT Assembly Process and Implementation

Solder Paste Application and Stenciling

The SMT Assembly process begins with the precise application of solder paste onto the PCB pads using stenciling techniques. This critical first step determines the quality and reliability of the final solder joints. Modern SMT Assembly lines utilize laser-cut stencils that provide exceptional accuracy in solder paste deposition. The paste composition includes flux materials that facilitate proper wetting and prevent oxidation during the reflow process. Quality control at this stage involves automated optical inspection systems that verify paste volume and placement accuracy.

Stencil design is crucial for successful SMT Assembly, requiring careful consideration of aperture size, shape, and wall thickness. The relationship between these parameters directly affects paste release characteristics and final joint quality. Advanced SMT Assembly facilities often employ multiple stencil configurations to accommodate components with varying pitch requirements on the same PCB. Environmental controls during paste application ensure consistent viscosity and prevent contamination that could compromise assembly reliability.

Component Placement and Alignment

Component placement represents the heart of the SMT Assembly process, where precision and speed converge to create reliable electronic assemblies. Modern pick-and-place equipment used in SMT Assembly can achieve placement accuracies of ±25 micrometers or better, ensuring proper component alignment even with fine-pitch components. The machines utilize advanced vision systems that can identify component orientation and make real-time corrections during placement. Feeder systems supply components in tape-and-reel format, enabling continuous operation and reducing changeover times.

The sophistication of modern SMT Assembly equipment allows for handling of components ranging from large connectors to tiny 01005 passive components. Programming flexibility enables quick setup changes for different product variants, making SMT Assembly suitable for both high-volume production and prototype development. Machine optimization algorithms continuously monitor and adjust placement parameters to maintain optimal throughput while ensuring quality standards. The integration of artificial intelligence in newer SMT Assembly systems enables predictive maintenance and process optimization.

Quality Control in SMT Assembly

Inspection Technologies and Methods

Quality control in SMT Assembly relies heavily on automated inspection technologies that can detect defects at various stages of the assembly process. Automated Optical Inspection systems examine component placement accuracy, solder joint quality, and overall assembly integrity. These systems use high-resolution cameras and sophisticated image processing algorithms to identify defects that might be missed by human operators. In-Circuit Testing and Functional Testing verify electrical performance and ensure that the assembled product meets specification requirements.

X-ray inspection has become increasingly important in SMT Assembly quality control, particularly for components with hidden solder joints such as Ball Grid Arrays. This non-destructive testing method can reveal internal defects like voids, bridges, or insufficient solder that cannot be detected through optical inspection alone. Statistical Process Control methods help maintain consistent quality in SMT Assembly by monitoring key process parameters and identifying trends that might indicate developing problems. Real-time feedback systems enable immediate corrective action when deviations are detected.

Defect Prevention and Correction

Preventing defects in SMT Assembly requires a comprehensive approach that addresses potential issues at every stage of the process. Design for Manufacturing principles ensure that PCB layouts and component selections are optimized for reliable assembly. Material management systems maintain proper storage conditions for components and solder paste to prevent moisture absorption and degradation. Process documentation and operator training ensure consistent execution of SMT Assembly procedures across different shifts and production lines.

When defects are detected in SMT Assembly, systematic root cause analysis helps identify the underlying issues and implement effective corrective measures. Rework procedures for SMT Assembly require specialized equipment and techniques due to the small size and close proximity of components. Hot air rework stations and infrared heating systems enable selective component removal and replacement without damaging adjacent parts. Continuous improvement methodologies help refine SMT Assembly processes over time, reducing defect rates and improving overall efficiency.

Applications and Industry Impact

Consumer Electronics and Mobile Devices

The consumer electronics industry has been fundamentally transformed by SMT Assembly technology, enabling the development of increasingly sophisticated and compact devices. Smartphones, tablets, and wearable devices rely extensively on SMT Assembly to achieve their remarkable miniaturization while maintaining complex functionality. The high component density possible with SMT Assembly allows manufacturers to integrate multiple functions into single devices, creating the convergence products that define modern consumer electronics. Advanced SMT Assembly techniques enable the production of flexible and rigid-flex circuits used in foldable devices and curved displays.

Gaming consoles, smart home devices, and Internet of Things products all depend on SMT Assembly for their compact form factors and reliable operation. The automotive electronics sector has also embraced SMT Assembly for developing advanced driver assistance systems, infotainment units, and electric vehicle control systems. The reliability requirements in automotive applications have driven innovations in SMT Assembly materials and processes, resulting in improved techniques that benefit all industries. High-volume production capabilities of SMT Assembly make consumer electronics affordable while maintaining quality standards.

Industrial and Medical Applications

Industrial automation systems increasingly rely on SMT Assembly for creating robust control systems that can operate in harsh environments. The precision and reliability of SMT Assembly make it ideal for medical device manufacturing, where failure is not an option. Implantable devices, diagnostic equipment, and surgical instruments all utilize SMT Assembly techniques to achieve the miniaturization and performance required for medical applications. The traceability and documentation capabilities of modern SMT Assembly lines support the regulatory requirements common in medical device manufacturing.

Aerospace and defense applications present unique challenges that SMT Assembly technology continues to address through specialized materials and processes. The ability to create lightweight, high-performance electronics through SMT Assembly is crucial for satellite systems, avionics, and military equipment. Environmental testing and qualification procedures for SMT Assembly in these applications often exceed commercial requirements, driving innovations that eventually benefit consumer products. The scalability of SMT Assembly processes enables both prototype development and high-volume production to meet diverse market needs.

Future Trends and Innovations

Emerging Technologies and Materials

The future of SMT Assembly is being shaped by emerging technologies that promise even greater capabilities and efficiency. Three-dimensional component stacking through Package-on-Package and System-in-Package approaches is expanding the possibilities for compact electronic design. Advanced materials including lead-free solders with improved reliability characteristics are being developed specifically for next-generation SMT Assembly applications. Conductive adhesives and alternative joining methods are being explored for temperature-sensitive components and flexible substrates.

Artificial intelligence integration in SMT Assembly equipment is enabling predictive quality control and autonomous optimization of process parameters. Machine learning algorithms can identify subtle patterns in production data that indicate potential quality issues before defects occur. Digital twin technology allows virtual optimization of SMT Assembly lines before physical implementation, reducing development time and costs. Collaborative robotics is being integrated into SMT Assembly operations to handle specialized tasks that require human-like dexterity while maintaining automated efficiency.

Industry 4.0 Integration

The integration of Industry 4.0 principles is revolutionizing SMT Assembly operations through enhanced connectivity and data analytics. Smart factory concepts enable real-time monitoring and control of SMT Assembly processes from anywhere in the world. Blockchain technology is being explored for component traceability and supply chain security in SMT Assembly applications. Cloud-based manufacturing execution systems provide centralized control and monitoring of distributed SMT Assembly operations.

Augmented reality systems are being developed to assist operators in SMT Assembly setup and maintenance procedures, reducing training time and improving accuracy. Predictive maintenance algorithms analyze equipment performance data to schedule maintenance activities before failures occur, minimizing downtime in SMT Assembly operations. The convergence of these technologies is creating SMT Assembly systems that are more flexible, efficient, and capable of producing increasingly complex electronic products with minimal human intervention.

FAQ

What makes SMT Assembly more efficient than through-hole assembly

SMT Assembly offers superior efficiency through automated component placement, higher component density, and faster processing speeds. The surface mounting approach eliminates the need for drilling holes in PCBs and allows components to be placed on both sides of the board. Automated pick-and-place machines can handle thousands of components per hour with exceptional accuracy, while reflow soldering processes multiple joints simultaneously. These factors combine to significantly reduce assembly time and labor costs compared to traditional through-hole methods.

How does component size affect SMT Assembly processes

Component size directly influences SMT Assembly equipment requirements, placement accuracy, and handling procedures. Smaller components like 01005 passives require specialized feeders and enhanced vision systems for proper placement. Fine-pitch components demand higher placement accuracy and more precise solder paste application. Larger components may require different heating profiles during reflow soldering and specialized handling to prevent warpage or damage. Modern SMT Assembly lines are designed with flexibility to accommodate the full range of component sizes used in contemporary electronics.

What quality standards apply to SMT Assembly operations

SMT Assembly operations typically follow IPC standards including IPC-A-610 for acceptability criteria and IPC-J-STD-001 for soldering requirements. ISO 9001 quality management systems provide the framework for consistent SMT Assembly processes. Industry-specific standards such as ISO 13485 for medical devices or AS9100 for aerospace applications may impose additional requirements. Many SMT Assembly facilities also maintain certifications for environmental management and workplace safety to ensure comprehensive quality coverage.

How is SMT Assembly adapted for prototype versus production volumes

SMT Assembly processes can be scaled from prototype quantities to high-volume production through equipment selection and process optimization. Prototype SMT Assembly often uses smaller, more flexible machines that can handle frequent changeovers and small batch sizes. Production SMT Assembly utilizes high-speed lines optimized for specific products with minimal changeover time. Setup procedures, quality control methods, and documentation requirements may vary between prototype and production SMT Assembly to balance flexibility with efficiency while maintaining quality standards throughout all volume levels.