Surface Mount Technology has revolutionized modern electronics manufacturing, becoming the cornerstone of high-volume production across industries worldwide. This advanced assembly technique enables manufacturers to achieve unprecedented levels of precision, efficiency, and cost-effectiveness when producing electronic devices at scale. The transition from traditional through-hole components to surface-mounted designs has fundamentally transformed how electronic products are conceived, designed, and manufactured in today's competitive marketplace.

The adoption of surface mount technology has enabled electronics manufacturers to meet the growing demand for smaller, faster, and more powerful devices while maintaining strict quality standards. From smartphones and tablets to automotive control systems and medical devices, SMT assembly processes have become essential for producing the complex electronic components that power our modern world. Understanding the advantages and applications of this technology is crucial for manufacturers seeking to optimize their production capabilities and remain competitive in rapidly evolving markets.

Fundamental Advantages of Surface Mount Technology

Enhanced Component Density and Miniaturization

Surface mount technology enables manufacturers to achieve significantly higher component density compared to traditional through-hole assembly methods. Components can be placed on both sides of the printed circuit board, effectively doubling the available real estate for electronic components. This increased density allows for more sophisticated functionality within smaller form factors, meeting consumer demands for compact yet powerful electronic devices.

The miniaturization capabilities of SMT extend beyond simple space savings. Smaller components reduce parasitic capacitance and inductance, leading to improved electrical performance at higher frequencies. This characteristic makes SMT particularly valuable for high-speed digital applications, radio frequency circuits, and advanced communication systems where signal integrity is paramount.

Modern SMT components can be as small as 0201 packages, measuring just 0.6mm by 0.3mm. This extreme miniaturization enables the creation of ultra-compact devices while maintaining robust electrical connections and thermal performance. The precision placement of these tiny components requires sophisticated assembly equipment and rigorous quality control processes.

Superior Manufacturing Efficiency and Speed

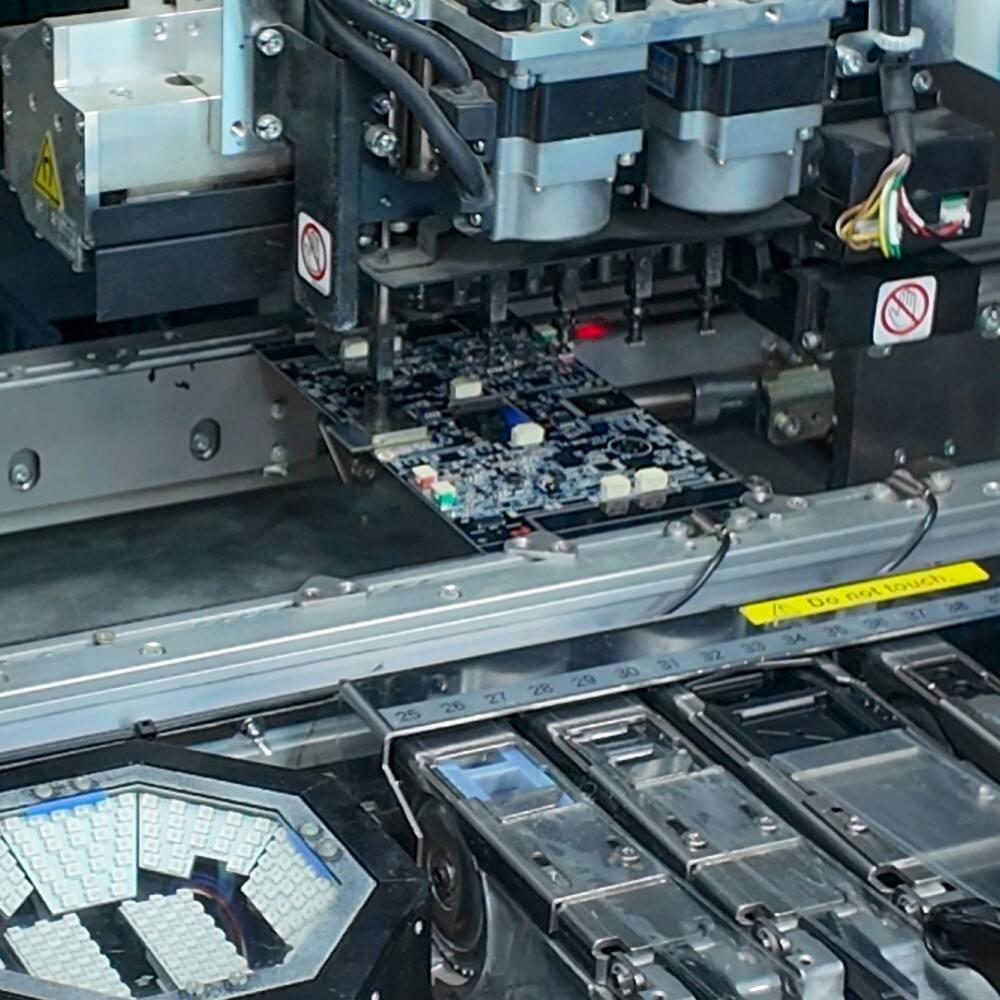

High-volume electronics production benefits tremendously from the automated assembly capabilities inherent in SMT processes. Pick-and-place machines can position thousands of components per hour with exceptional accuracy, dramatically reducing assembly time compared to manual or semi-automated through-hole insertion methods. This automation capability is essential for meeting the production volumes required in today's electronics markets.

The reflow soldering process used in SMT assembly allows entire circuit boards to be soldered simultaneously, rather than component by component. This batch processing approach significantly reduces manufacturing cycle times and enables consistent solder joint quality across all connections. Temperature profiles can be precisely controlled to optimize solder joint formation for different component types and board designs.

Quality control processes in SMT manufacturing can be highly automated, with optical inspection systems capable of detecting defects at microscopic levels. Automated optical inspection and X-ray inspection systems ensure consistent quality while maintaining high production throughput, reducing the need for manual inspection and rework.

Cost Benefits and Economic Advantages

Reduced Material and Labor Costs

Surface mount components typically cost less than their through-hole equivalents due to simplified packaging and manufacturing processes. The elimination of component leads and the smaller package sizes reduce material usage, resulting in lower component costs. Additionally, the high level of automation possible with SMT assembly reduces labor requirements, leading to significant cost savings in high-volume production scenarios.

The elimination of drilling holes in printed circuit boards reduces manufacturing costs and complexity. Fewer mechanical operations translate to reduced tool wear, lower maintenance costs, and improved production efficiency. The ability to place components on both sides of the board maximizes the utilization of expensive PCB real estate, further improving cost-effectiveness.

Inventory management becomes more efficient with SMT components due to standardized packaging formats like tape and reel. This standardization reduces handling costs, improves storage efficiency, and enables better inventory tracking and control systems. Automated material handling systems can manage component inventory with minimal human intervention.

Improved Yield and Reduced Waste

The precision and repeatability of SMT assembly processes result in higher production yields compared to through-hole assembly methods. Consistent solder paste application, accurate component placement, and controlled reflow profiles minimize assembly defects and improve first-pass yield rates. Higher yields directly translate to reduced manufacturing costs and improved profitability.

Defect detection and correction in SMT processes can often be performed before final assembly completion. In-line inspection systems can identify placement errors or solder paste issues early in the process, allowing for corrections before components are permanently soldered. This early detection capability reduces waste and rework costs.

The standardized nature of SMT processes enables better process control and statistical analysis. Manufacturing data can be collected and analyzed to identify trends, optimize processes, and prevent defects before they occur. This predictive approach to quality management further improves yield rates and reduces waste.

Technical Performance and Reliability

Enhanced Electrical Performance

Surface mount technology offers superior electrical performance characteristics, particularly important for high-frequency and high-speed applications. The shorter connection paths between components and reduced parasitic effects result in better signal integrity and reduced electromagnetic interference. These performance advantages are crucial for modern electronic devices operating at increasingly higher frequencies.

The mechanical stability of surface-mounted components provides excellent vibration and shock resistance. The direct attachment to the PCB surface, combined with properly designed solder joints, creates robust mechanical connections that can withstand harsh operating environments. This reliability is essential for automotive, aerospace, and industrial applications where equipment must operate reliably under challenging conditions.

Thermal performance is enhanced through the improved thermal conduction paths available with surface mount components. Heat generated by active components can be more effectively dissipated through the PCB substrate and thermal vias, enabling higher power density designs and improved reliability. Thermal management strategies can be more easily implemented with the design flexibility offered by SMT.

Design Flexibility and Innovation

The compact nature of SMT components enables innovative product designs that would be impossible with through-hole technology. Multi-layer PCBs can incorporate complex routing patterns, embedded components, and advanced materials to achieve specific performance objectives. This design flexibility drives innovation in industries ranging from consumer electronics to aerospace applications.

Component placement flexibility allows designers to optimize signal routing, minimize crosstalk, and implement advanced circuit topologies. The ability to place components on both sides of the PCB provides additional routing layers and enables more compact designs. Advanced design software tools can optimize component placement and routing to achieve specific performance targets.

New packaging technologies continue to push the boundaries of what is possible with SMT. Ball grid arrays, chip-scale packages, and system-in-package solutions enable unprecedented levels of integration and performance. These advanced packaging technologies rely on the precision and capability of modern SMT assembly processes.

Industry Applications and Market Adoption

Consumer Electronics and Mobile Devices

The consumer electronics industry has been the primary driver of SMT technology advancement and adoption. Smartphones, tablets, laptops, and wearable devices all rely heavily on surface mount technology to achieve the required form factors and functionality. The constant demand for smaller, more powerful devices continues to push the limits of SMT capabilities and drive technological innovation.

Gaming consoles, smart home devices, and entertainment systems utilize SMT assembly to pack sophisticated processing power into consumer-friendly form factors. The high-volume production requirements of these markets have driven improvements in SMT assembly equipment and processes, making the technology more efficient and cost-effective for all applications.

Emerging technologies like augmented reality, virtual reality, and Internet of Things devices represent new frontiers for SMT applications. These applications often require specialized component packages and assembly techniques that push the boundaries of current SMT capabilities, driving continued innovation in the field.

Automotive and Industrial Applications

The automotive industry has embraced SMT for electronic control units, infotainment systems, and advanced driver assistance systems. The reliability and performance advantages of surface mount technology are particularly important in automotive applications where failure is not acceptable. Advanced automotive electronics require the precision and reliability that only modern SMT processes can provide.

Industrial automation and control systems benefit from the robustness and reliability of SMT assemblies. Process control systems, programmable logic controllers, and sensor interfaces rely on surface mount technology to operate reliably in harsh industrial environments. The ability to create ruggedized electronic assemblies using SMT processes has enabled the automation of many industrial processes.

Medical device manufacturing has adopted SMT for critical applications where reliability and miniaturization are essential. Implantable devices, diagnostic equipment, and monitoring systems utilize surface mount technology to achieve the required performance and safety standards. The biocompatibility and reliability requirements of medical applications have driven advances in SMT materials and processes.

Future Trends and Technological Developments

Advanced Materials and Process Innovations

The development of new solder alloys and assembly materials continues to improve the performance and reliability of SMT processes. Lead-free solders, conductive adhesives, and advanced flux formulations enable better joint formation and enhanced reliability under extreme conditions. Research into new materials aims to address the challenges of higher operating temperatures and more demanding environmental conditions.

Additive manufacturing technologies are beginning to integrate with traditional SMT processes, enabling the creation of three-dimensional electronic assemblies. Printed electronics and flexible substrates represent new frontiers for surface mount technology applications. These emerging technologies may revolutionize how electronic devices are designed and manufactured in the future.

Artificial intelligence and machine learning are being integrated into SMT assembly processes to optimize performance and predict maintenance requirements. Smart factory concepts utilize real-time data analysis to optimize process parameters and improve quality. These technological advances promise to make SMT manufacturing even more efficient and reliable.

Miniaturization and Integration Trends

The ongoing trend toward smaller component packages continues to drive SMT technology development. Embedded components, where passive components are integrated directly into the PCB substrate, represent the ultimate in miniaturization. These technologies require advanced assembly processes and specialized equipment capabilities.

System-in-package and module technologies are enabling higher levels of integration and functionality within single SMT components. These advanced packaging approaches combine multiple semiconductor dies and passive components into single packages that can be assembled using standard SMT processes. This integration trend enables more powerful and compact electronic devices.

Heterogeneous integration technologies are combining different semiconductor technologies and materials into single packages. These advanced assemblies require specialized SMT processes and equipment to handle the diverse thermal and mechanical requirements of different technologies. The continued development of these integration technologies will drive further advances in SMT capabilities.

FAQ

What makes SMT more suitable for high-volume production than through-hole technology?

Surface Mount Technology offers several key advantages for high-volume production including faster automated assembly speeds, higher component density, reduced material costs, and better process repeatability. The ability to place components on both sides of the PCB and the batch processing nature of reflow soldering significantly reduce manufacturing cycle times compared to through-hole assembly methods.

How does SMT improve product reliability and performance?

SMT improves reliability through stronger mechanical connections, better vibration resistance, and superior electrical performance due to shorter connection paths. The precision manufacturing processes result in more consistent solder joints and reduced parasitic effects, leading to better signal integrity and enhanced overall product performance, especially in high-frequency applications.

What are the cost benefits of implementing SMT in manufacturing?

SMT reduces manufacturing costs through lower component prices, reduced labor requirements due to automation, elimination of PCB drilling operations, and improved production yields. The standardized packaging and handling systems also reduce inventory and material handling costs, while the higher component density maximizes the utilization of expensive PCB real estate.

What industries benefit most from SMT assembly processes?

Consumer electronics, automotive, telecommunications, medical devices, aerospace, and industrial automation industries all benefit significantly from SMT assembly. Any application requiring miniaturization, high reliability, or high-volume production can leverage the advantages of surface mount technology to achieve better performance and cost-effectiveness.