Surface Mount Technology has revolutionized the electronics manufacturing industry, fundamentally changing how components are assembled onto printed circuit boards. This advanced assembly method has become the backbone of modern electronic device production, offering unprecedented precision and efficiency. The evolution from through-hole technology to surface mount processes represents one of the most significant technological advancements in electronics manufacturing history. Understanding the comprehensive benefits of this technology is crucial for manufacturers, engineers, and businesses seeking optimal production outcomes.

Enhanced Miniaturization and Component Density

Compact Design Capabilities

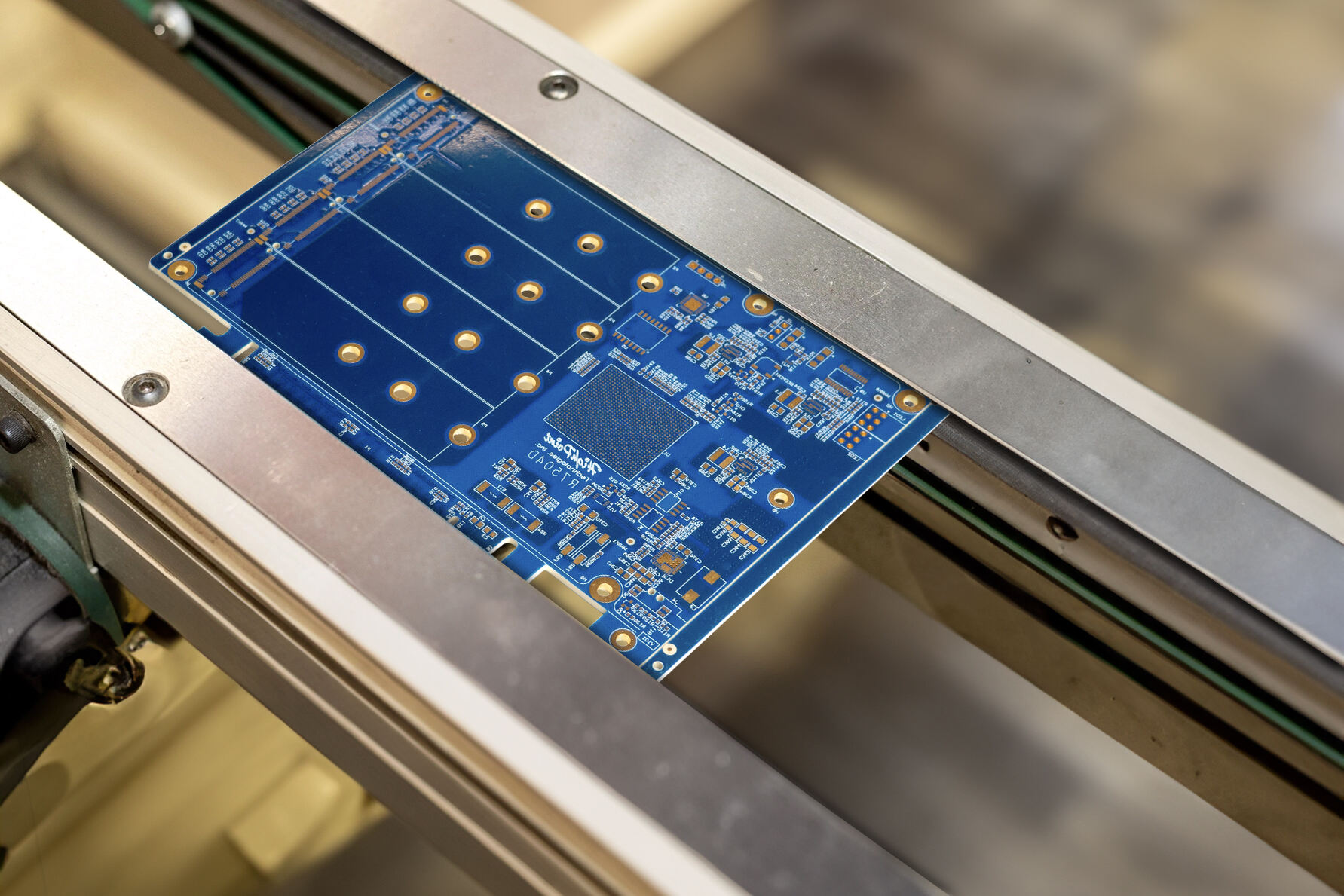

Surface Mount Technology enables manufacturers to achieve remarkable miniaturization in electronic devices by mounting components directly onto the board surface. This approach eliminates the need for component leads to pass through drilled holes, allowing for much smaller component packages. The reduction in component size translates directly to more compact final products, meeting consumer demands for portable and lightweight electronic devices. Modern smartphones, tablets, and wearable technology would be impossible without the miniaturization capabilities that SMT provides.

The space efficiency gained through surface mount assembly is particularly evident in high-density applications where every millimeter matters. Components can be placed closer together without interfering with each other, maximizing the functional capacity of each square inch of board space. This density advantage becomes increasingly important as electronic devices continue to incorporate more features while maintaining or reducing their physical footprint.

Increased Component Count Per Board

Surface mount assembly allows for significantly higher component counts on both sides of a printed circuit board compared to traditional through-hole methods. This dual-sided placement capability effectively doubles the available real estate for component placement. The ability to populate both sides of a board with components means that complex circuits can be implemented in much smaller form factors than previously possible.

The increased component density also enables more sophisticated circuit designs within the same physical constraints. Engineers can incorporate additional functionality, improved performance characteristics, and enhanced features without expanding the board size. This capability is particularly valuable in applications where space constraints are critical, such as medical implants, automotive electronics, and consumer mobile devices.

Superior Manufacturing Efficiency and Speed

Automated Assembly Processes

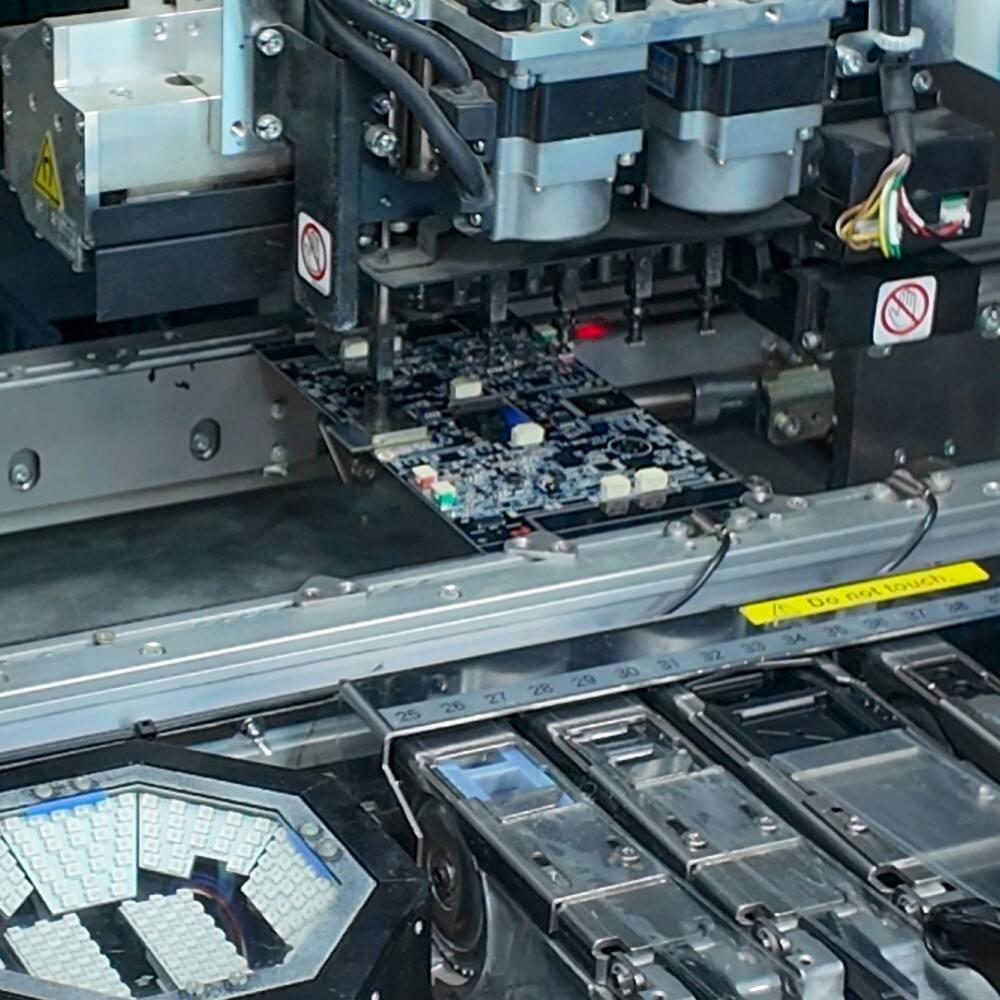

The surface mount process is ideally suited for automated manufacturing, significantly reducing production time and labor costs. Pick-and-place machines can accurately position thousands of components per hour with precision that far exceeds manual assembly capabilities. This automation reduces human error, increases consistency, and enables 24-hour production cycles that dramatically improve manufacturing throughput.

The programmable nature of SMT equipment allows for rapid changeovers between different product configurations, making it economical to produce both high-volume and low-volume runs. This flexibility is crucial in today's market where product life cycles are short and customization is increasingly important. The ability to quickly reprogram machines for different products reduces setup time and increases overall equipment effectiveness.

Reduced Assembly Time and Labor Costs

Surface Mount Technology significantly reduces the time required for PCB assembly compared to through-hole methods. The elimination of hole drilling, component lead preparation, and wave soldering processes streamlines the entire manufacturing workflow. Components are placed and soldered simultaneously through reflow processes, creating a more efficient production line with fewer manual intervention points.

Labor cost reductions are substantial when implementing surface mount processes, as fewer skilled operators are required to manage automated equipment compared to manual through-hole assembly. The reduced touch labor requirements translate to lower per-unit manufacturing costs, improved profit margins, and more competitive pricing in the marketplace. These cost advantages become increasingly significant as production volumes scale upward.

Improved Electrical Performance Characteristics

Enhanced Signal Integrity

Surface mount components offer superior electrical performance characteristics due to shorter connection paths and reduced parasitic inductance and capacitance. The direct mounting of components to board surfaces eliminates the electrical discontinuities that occur with through-hole leads, resulting in cleaner signal transmission and reduced electromagnetic interference. This improved signal integrity is critical for high-frequency applications and sensitive analog circuits.

The reduced lead lengths inherent in surface mount design minimize signal delays and improve overall circuit performance. This advantage becomes increasingly important as operating frequencies continue to rise across all electronic applications. High-speed digital circuits, RF applications, and precision analog systems all benefit from the superior electrical characteristics that surface mount assembly provides.

Better Thermal Management

Surface mount assembly enables better thermal management through improved heat dissipation pathways. Components mounted directly to board surfaces can transfer heat more effectively to the PCB substrate and any attached heat sinks or thermal management systems. The larger contact area between surface mount components and the board creates more efficient thermal conduction paths compared to through-hole mounting methods.

Enhanced thermal performance is particularly important in power electronics and high-performance computing applications where component temperatures directly impact reliability and performance. The ability to more effectively manage heat allows for higher power densities and improved system reliability. Modern thermal interface materials and board designs work synergistically with surface mount technology to create highly effective thermal management solutions.

Cost Effectiveness and Economic Advantages

Material Cost Savings

Surface mount components typically cost less than their through-hole counterparts due to simplified packaging requirements and reduced material usage. The elimination of long leads and simplified component construction reduces raw material costs and manufacturing complexity. These savings are passed on to electronics manufacturers, creating more competitive final product pricing and improved profit margins.

Board fabrication costs are also reduced with surface mount technology since fewer holes need to be drilled and plated. The simplified board design requirements reduce manufacturing complexity and processing time, resulting in lower per-unit board costs. These savings become increasingly significant in high-volume production scenarios where material costs represent a substantial portion of total manufacturing expenses.

Reduced Testing and Rework Costs

The precision and consistency of automated surface mount assembly results in higher first-pass yields and reduced testing time. Automated optical inspection systems can quickly verify component placement and solder joint quality, identifying defects before they progress through the manufacturing process. This early detection capability reduces downstream rework costs and improves overall manufacturing efficiency.

When rework is necessary, surface mount technology often enables easier component replacement and repair compared to through-hole methods. Components can be removed and replaced using controlled heating processes that minimize damage to surrounding components and board materials. This repairability helps maintain high yield rates and reduces scrap costs throughout the manufacturing process.

Quality and Reliability Improvements

Consistent Solder Joint Quality

Reflow soldering processes used in surface mount assembly create highly consistent and reliable solder joints. The controlled temperature profiles and uniform heating ensure that all joints reach proper metallurgical bonding conditions simultaneously. This consistency eliminates the variability often associated with wave soldering and hand soldering methods used in through-hole assembly.

The self-aligning properties of surface tension during reflow soldering help correct minor component placement errors, further improving joint quality and reliability. Components naturally align themselves to optimal positions during the soldering process, reducing stress concentrations and improving mechanical stability. This self-correction capability contributes to higher yields and more reliable final products.

Enhanced Mechanical Stability

Surface mount components exhibit excellent mechanical stability due to their low profile and secure attachment to board surfaces. The reduced component height lowers the center of gravity and decreases mechanical stress during handling and operation. This stability is particularly important in portable devices and applications subject to vibration or impact loads.

The distributed stress patterns created by surface mount attachment methods provide better resistance to thermal cycling and mechanical shock compared to through-hole mounting. Multiple solder joints distribute mechanical loads more evenly, reducing stress concentrations that could lead to component failure. This improved mechanical stability translates to longer product life and higher reliability in demanding applications.

Design Flexibility and Innovation

Advanced Component Technologies

Surface Mount Technology enables the use of advanced component technologies that would be impossible to implement with through-hole methods. Ultra-fine pitch components, ball grid arrays, and chip-scale packages all require surface mount assembly techniques. These advanced package types offer superior electrical performance, higher functionality, and smaller form factors that drive innovation across the electronics industry.

The availability of specialized surface mount components continues to expand, providing engineers with an ever-growing palette of functional blocks to incorporate into their designs. High-performance analog components, sophisticated digital processors, and specialized sensor packages are all available in surface mount configurations that enable new product capabilities and improved performance characteristics.

Multi-Layer PCB Optimization

Surface mount assembly works synergistically with multi-layer PCB designs to maximize functionality within minimal space constraints. The elimination of through-holes preserves more routing layers for signal traces and power distribution, enabling more complex interconnection schemes. This optimization is crucial for high-speed digital designs where controlled impedance routing and proper power distribution are essential for proper operation.

The combination of surface mount components and advanced PCB stackup designs enables the creation of highly integrated systems that would require multiple boards using traditional through-hole methods. This system-level integration reduces interconnection complexity, improves reliability, and enables new product architectures that were previously impractical or impossible to implement.

FAQ

What types of products benefit most from surface mount assembly?

Surface mount assembly provides the greatest benefits for products requiring high component density, miniaturization, or high-volume production. Consumer electronics like smartphones, tablets, and laptops rely heavily on SMT for their compact form factors. Industrial control systems, automotive electronics, medical devices, and telecommunications equipment also benefit significantly from the space efficiency and reliability improvements that surface mount technology provides.

How does surface mount technology impact production scalability?

Surface Mount Technology dramatically improves production scalability through automated assembly processes that can operate continuously with minimal human intervention. The programmable nature of SMT equipment allows manufacturers to quickly switch between different products, making both high-volume and low-volume production economically viable. This flexibility enables manufacturers to respond quickly to market demands and efficiently manage diverse product portfolios.

What are the quality advantages of SMT over through-hole assembly?

SMT offers several quality advantages including more consistent solder joints through reflow processes, reduced mechanical stress on components, and better electrical performance due to shorter connection paths. The automated assembly process reduces human error and provides repeatable, precise component placement. Additionally, the lower profile of surface mount components provides better mechanical stability and resistance to vibration and shock.

How does SMT contribute to environmental sustainability in electronics manufacturing?

Surface Mount Technology contributes to environmental sustainability through reduced material usage, smaller component packages, and more efficient manufacturing processes. The miniaturization enabled by SMT reduces the overall material content of electronic products, while the higher efficiency of automated assembly reduces energy consumption per unit produced. Additionally, the improved reliability of SMT assemblies extends product life, reducing electronic waste and the need for frequent replacements.