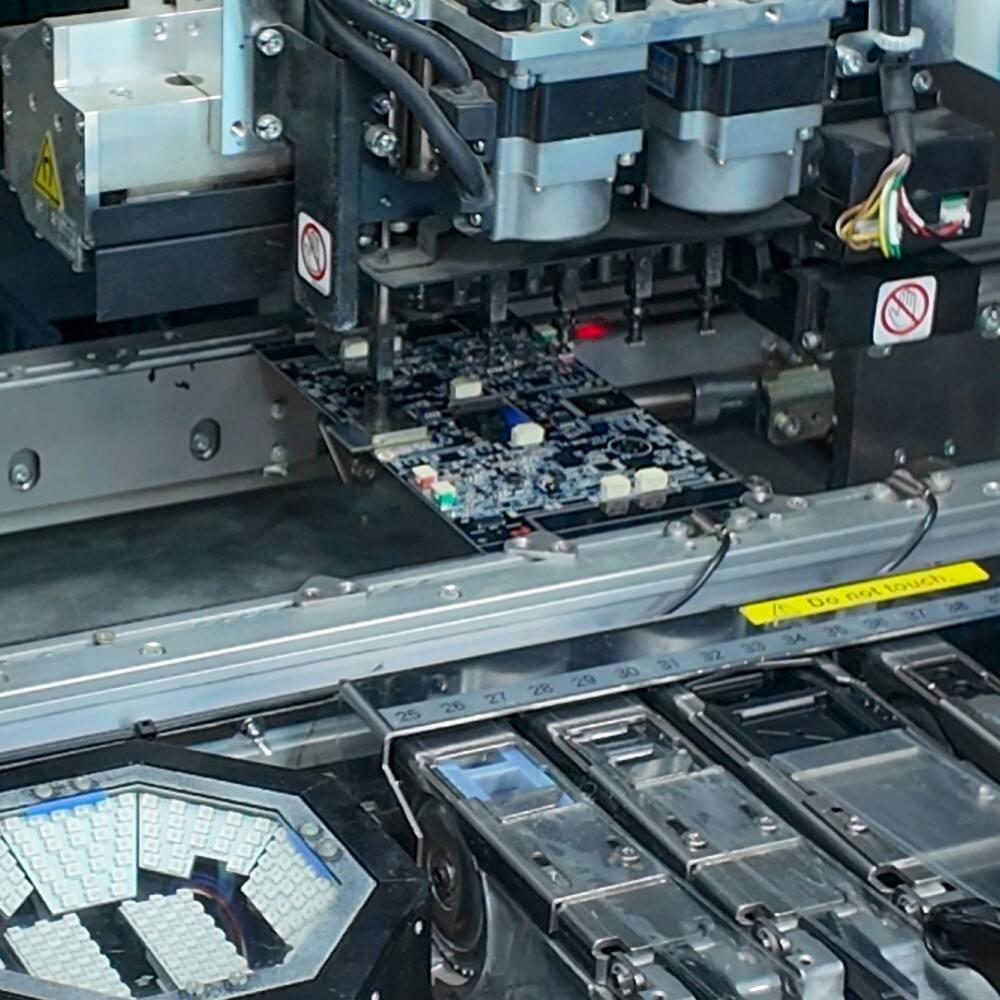

Modern electronics manufacturing relies heavily on advanced assembly techniques that ensure both precision and efficiency. Professional SMT Assembly services have revolutionized the way electronic components are mounted onto printed circuit boards, offering unparalleled accuracy and reliability. This sophisticated manufacturing process involves placing surface-mount components directly onto PCB pads using automated equipment and specialized techniques. The evolution of SMT Assembly has transformed the electronics industry by enabling manufacturers to create smaller, more powerful devices while maintaining exceptional quality standards.

Enhanced Manufacturing Precision and Quality

Advanced Component Placement Accuracy

Professional SMT Assembly services deliver exceptional component placement accuracy through state-of-the-art pick-and-place machines. These sophisticated systems can position components with tolerances as tight as ±0.02mm, ensuring optimal electrical connections and mechanical stability. The precision achieved through professional SMT Assembly significantly reduces the risk of component misalignment, which can lead to circuit failures or performance degradation. Automated vision systems continuously monitor component placement during the assembly process, providing real-time feedback and corrections when necessary.

Quality control measures integrated into professional SMT Assembly processes include automated optical inspection (AOI) systems that detect placement errors, solder joint defects, and component orientation issues. These inspection systems operate at high speeds while maintaining exceptional accuracy, ensuring that every assembled board meets stringent quality standards. The combination of precise placement equipment and comprehensive inspection systems results in significantly lower defect rates compared to manual assembly methods.

Consistent Solder Joint Formation

Professional SMT Assembly facilities utilize advanced reflow soldering techniques that create uniform, reliable solder joints across all components. Temperature profiling systems ensure that each board experiences optimal heating and cooling cycles, promoting proper solder wetting and intermetallic compound formation. This controlled approach to soldering eliminates common defects such as cold joints, tombstoning, and bridging that can compromise circuit reliability.

The use of nitrogen atmosphere reflow ovens in professional SMT Assembly operations further enhances solder joint quality by preventing oxidation during the soldering process. This controlled environment ensures consistent wetting characteristics and reduces the formation of voids within solder joints. Professional assembly services also employ sophisticated solder paste printing techniques that deposit precise amounts of solder paste onto each pad, contributing to uniform joint formation.

Cost Efficiency and Production Scalability

Reduced Material Waste and Component Loss

Professional SMT Assembly services implement sophisticated inventory management systems that minimize component waste and reduce material costs. Automated feeders and component storage systems protect sensitive electronic components from environmental damage while ensuring accurate component tracking throughout the assembly process. These systems significantly reduce component loss due to handling errors or environmental exposure, resulting in lower overall material costs.

Advanced programming and setup optimization in professional SMT Assembly operations minimize material waste through efficient placement algorithms and optimized feeder arrangements. Machine learning algorithms analyze historical production data to predict optimal setup configurations, reducing changeover times and minimizing component waste during production transitions. This intelligent approach to production planning results in substantial cost savings, particularly for high-volume manufacturing runs.

Accelerated Production Throughput

Professional SMT Assembly facilities leverage high-speed placement equipment capable of positioning thousands of components per hour. Multi-head placement machines with advanced motion control systems enable simultaneous component placement, dramatically reducing assembly cycle times. The integration of parallel processing techniques allows multiple boards to be assembled simultaneously, maximizing production throughput while maintaining consistent quality standards.

Lean manufacturing principles implemented in professional SMT Assembly operations eliminate bottlenecks and optimize production flow. Continuous improvement methodologies ensure that production processes are constantly refined to achieve maximum efficiency. Advanced scheduling systems coordinate material flow, equipment utilization, and workforce allocation to minimize downtime and maximize productive capacity.

Technical Advantages and Innovation

Support for Advanced Component Technologies

Professional SMT Assembly services possess the specialized equipment and expertise required to handle cutting-edge component technologies. Ultra-fine pitch components, ball grid arrays (BGAs), and chip-scale packages (CSPs) require sophisticated placement equipment and precise process control that is only available through professional assembly services. These advanced components enable the development of smaller, more powerful electronic devices with enhanced functionality.

Specialized handling techniques for moisture-sensitive components ensure that sensitive devices remain within specified humidity and temperature parameters throughout the assembly process. Professional SMT Assembly facilities maintain controlled environments with appropriate dry storage systems and moisture indicator cards to prevent component damage. Advanced baking and dry storage procedures prepare moisture-sensitive components for reliable assembly without compromising their electrical characteristics.

Process Optimization and Engineering Support

Experienced engineering teams at professional SMT Assembly facilities provide design for manufacturability (DFM) analysis to optimize PCB layouts for efficient assembly. This engineering support helps identify potential assembly challenges early in the design process, reducing development time and manufacturing costs. Process engineers work closely with clients to develop custom assembly procedures that address specific product requirements and performance objectives.

Thermal profiling and process optimization services ensure that each product receives appropriate reflow parameters tailored to its specific component mix and PCB characteristics. Professional SMT Assembly providers utilize advanced simulation software to predict thermal behavior and optimize process parameters before production begins. This proactive approach minimizes the risk of thermal damage to sensitive components while ensuring reliable solder joint formation.

Quality Assurance and Compliance Benefits

Comprehensive Testing and Validation

Professional SMT Assembly services incorporate extensive testing protocols that verify both assembly quality and functional performance. In-circuit testing (ICT) systems verify component placement, solder joint integrity, and basic circuit functionality before final inspection. Functional testing procedures validate that assembled circuits meet specified performance parameters under various operating conditions.

Advanced X-ray inspection systems enable non-destructive evaluation of hidden solder joints, particularly those beneath BGA and QFN components. This sophisticated inspection capability detects internal defects such as voids, cracks, and incomplete wetting that cannot be identified through visual inspection methods. Professional SMT Assembly providers utilize these advanced inspection techniques to ensure comprehensive quality validation.

Industry Certification and Compliance

Professional SMT Assembly facilities maintain certifications to industry standards such as IPC-A-610, ISO 9001, and AS9100, ensuring that assembly processes meet stringent quality requirements. These certifications demonstrate commitment to quality excellence and provide customers with confidence in the reliability of assembled products. Regular audits and continuous improvement programs maintain certification compliance while driving ongoing process enhancements.

Traceability systems implemented in professional SMT Assembly operations provide complete documentation of component sources, process parameters, and quality test results for each assembled unit. This comprehensive traceability supports regulatory compliance requirements and enables rapid response to quality issues if they arise. Electronic records management systems ensure that quality documentation is securely stored and readily accessible for customer audits or regulatory inspections.

FAQ

What types of components can be assembled using professional SMT Assembly services

Professional SMT Assembly services can handle a wide variety of surface-mount components including resistors, capacitors, integrated circuits, connectors, and specialized devices such as BGAs, CSPs, and ultra-fine pitch components. These services also accommodate mixed-technology assemblies that combine surface-mount and through-hole components on the same PCB. Advanced placement equipment enables handling of components ranging from large power devices to microscopic passive components with exceptional precision.

How does professional SMT Assembly improve product reliability compared to manual assembly

Professional SMT Assembly significantly improves product reliability through automated placement systems that eliminate human error, controlled soldering processes that ensure consistent joint quality, and comprehensive inspection systems that detect defects before shipment. Automated processes maintain consistent placement accuracy and soldering parameters, while environmental controls protect components from contamination and moisture damage during assembly.

What volume requirements are suitable for professional SMT Assembly services

Professional SMT Assembly services accommodate projects ranging from prototype quantities to high-volume production runs. While setup costs may make very small quantities less economical, most professional facilities offer prototype services with quick turnaround times. High-volume production benefits significantly from automated assembly processes through reduced per-unit costs, consistent quality, and accelerated delivery schedules.

How long does the SMT Assembly process typically take from start to finish

SMT Assembly turnaround times vary depending on project complexity, component availability, and production volume. Simple assemblies with readily available components may be completed within 3-5 business days, while complex designs requiring custom programming or specialized components may take 2-3 weeks. Professional SMT Assembly providers work closely with customers to establish realistic delivery schedules based on specific project requirements and current production capacity.

Table of Contents

- Enhanced Manufacturing Precision and Quality

- Cost Efficiency and Production Scalability

- Technical Advantages and Innovation

- Quality Assurance and Compliance Benefits

-

FAQ

- What types of components can be assembled using professional SMT Assembly services

- How does professional SMT Assembly improve product reliability compared to manual assembly

- What volume requirements are suitable for professional SMT Assembly services

- How long does the SMT Assembly process typically take from start to finish