Selecting the right SMT Assembly partner is one of the most critical decisions that electronics manufacturers face in today's competitive market. Surface Mount Technology has revolutionized the electronics industry by enabling smaller, faster, and more efficient devices. However, the success of your product depends heavily on finding an SMT Assembly service provider who can deliver high-quality results while meeting your specific requirements. This comprehensive guide will help you navigate the complex process of choosing the ideal partner for your SMT Assembly needs, ensuring your products meet the highest standards of quality and reliability.

Understanding SMT Assembly Requirements

Technical Capabilities Assessment

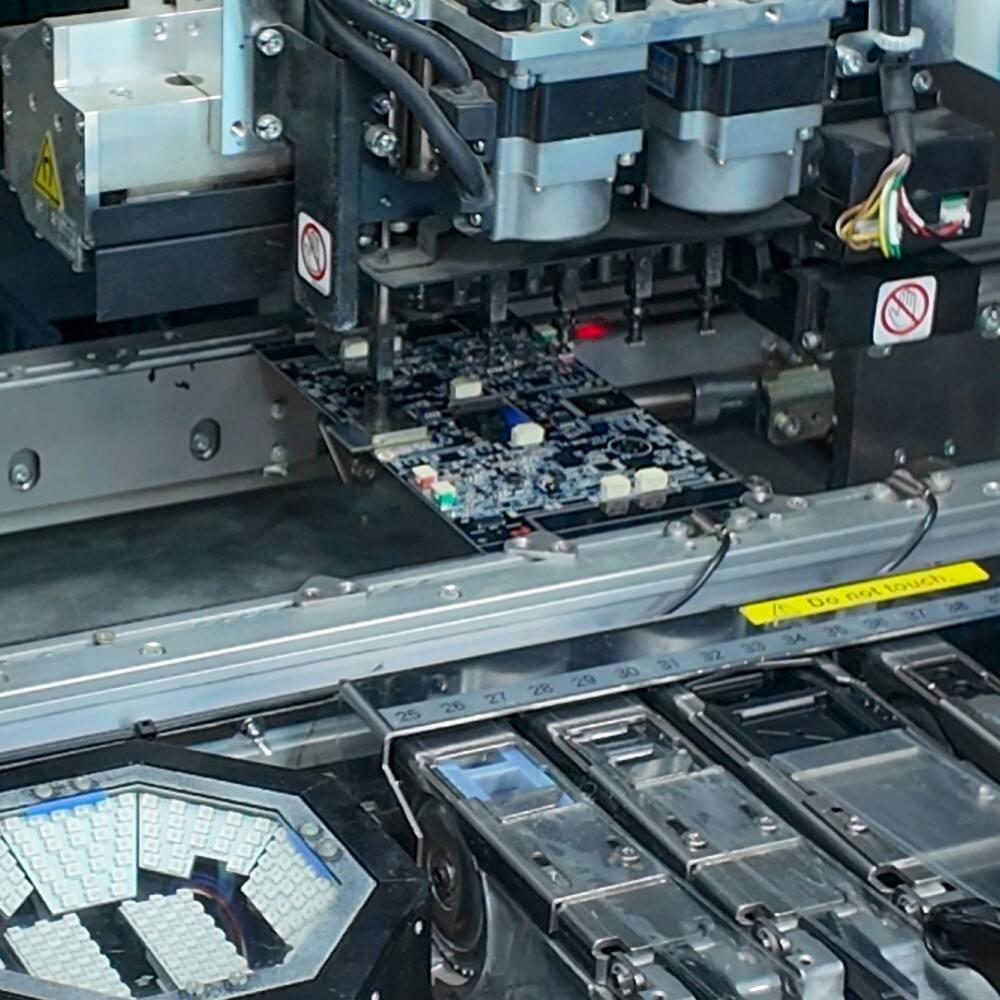

When evaluating potential SMT Assembly partners, the first step involves thoroughly assessing their technical capabilities. Modern SMT Assembly operations require sophisticated equipment capable of handling various component sizes, from large capacitors to microscopic chips measuring just 0.4mm x 0.2mm. Your chosen partner should demonstrate proficiency with advanced placement machines, reflow ovens, and inspection systems that can accommodate your specific component requirements. The facility should also maintain proper environmental controls, including temperature and humidity management, which are essential for consistent SMT Assembly quality.

Component compatibility represents another crucial technical consideration in SMT Assembly partnerships. Different projects may require unique component types, including BGAs, QFNs, flip chips, and standard passive components. Your partner should have experience handling the specific components your design requires and possess the necessary equipment for proper placement and soldering. Additionally, they should demonstrate knowledge of component orientation, polarity requirements, and thermal management considerations that affect SMT Assembly success rates.

Quality Management Systems

Quality management systems form the backbone of successful SMT Assembly operations. Industry certifications such as ISO 9001, IPC-A-610, and AS9100 indicate that your potential partner maintains standardized quality processes. These certifications ensure consistent SMT Assembly procedures, proper documentation, and continuous improvement practices. Your partner should also implement statistical process control methods to monitor key parameters throughout the SMT Assembly process, including paste printing, component placement accuracy, and reflow profile optimization.

Traceability systems are equally important in professional SMT Assembly services. Your partner should maintain comprehensive records of component lot numbers, assembly dates, operator information, and inspection results. This documentation becomes invaluable when addressing field issues or implementing design changes. The ability to trace specific components through the entire SMT Assembly process demonstrates professional manufacturing practices and regulatory compliance capabilities.

Evaluating Manufacturing Capabilities

Production Volume Flexibility

Production volume requirements significantly impact SMT Assembly partner selection. Some facilities excel at high-volume production runs with automated systems optimized for efficiency, while others specialize in low-volume, high-mix environments requiring frequent changeovers. Understanding your current and projected volume needs helps identify partners whose capabilities align with your business model. Consider both immediate requirements and future growth plans when evaluating SMT Assembly capacity.

Prototype and small-batch capabilities deserve special attention for companies in development phases. Many SMT Assembly providers offer rapid prototyping services with shorter lead times and flexible minimum order quantities. These services enable faster design iterations and market entry strategies. Your ideal partner should demonstrate experience with both prototype development and production scaling, ensuring smooth transitions as your products move from concept to commercial manufacturing.

Technology Integration

Modern SMT Assembly operations increasingly rely on advanced technologies for improved accuracy and efficiency. Automated optical inspection systems, X-ray inspection capabilities, and in-circuit testing represent standard expectations for professional assembly services. Your partner should utilize pick-and-place machines with vision systems for precise component placement and demonstrate proficiency with various soldering technologies, including selective soldering for through-hole components mixed with surface mount devices.

Data management and communication systems also play crucial roles in successful SMT Assembly partnerships. Look for providers who offer real-time production monitoring, online order tracking, and electronic data interchange capabilities. These systems facilitate better communication, reduce errors, and enable proactive issue resolution throughout the manufacturing process.

Supply Chain and Component Management

Procurement Expertise

Effective component procurement directly impacts SMT Assembly success and project timelines. Your ideal partner should maintain relationships with authorized distributors and demonstrate expertise in component sourcing, including obsolescence management and alternative component identification. They should also provide component engineering services, helping optimize designs for manufacturability and cost-effectiveness while maintaining performance requirements.

Inventory management capabilities represent another critical consideration in SMT Assembly partnerships. Professional providers maintain secure, climate-controlled component storage facilities with proper moisture sensitivity handling procedures. They should implement first-in-first-out inventory rotation and provide component aging reports to prevent reliability issues. Additionally, look for partners who offer consignment inventory programs or vendor-managed inventory services to reduce your working capital requirements.

Risk Mitigation Strategies

Supply chain disruptions can significantly impact SMT Assembly schedules and costs. Your chosen partner should demonstrate robust risk mitigation strategies, including multiple supplier relationships, safety stock management, and alternative component qualification processes. They should also maintain contingency plans for handling component shortages, natural disasters, or other supply chain interruptions that could affect your SMT Assembly projects.

Counterfeit component prevention represents a growing concern in electronics manufacturing. Professional SMT Assembly providers implement comprehensive anti-counterfeiting measures, including supplier verification, incoming inspection procedures, and component authentication testing. These measures protect both product reliability and brand reputation while ensuring regulatory compliance in sensitive applications.

Cost Considerations and Value Analysis

Pricing Structure Evaluation

SMT Assembly pricing involves multiple components beyond basic assembly labor costs. Understanding the complete cost structure helps make informed partner selection decisions. Setup fees, tooling costs, testing charges, and material handling fees can significantly impact overall project economics. Request detailed pricing breakdowns that itemize all potential charges and compare total cost of ownership rather than focusing solely on per-unit assembly costs.

Volume-based pricing tiers often provide opportunities for cost optimization in SMT Assembly projects. Many providers offer reduced pricing for larger quantities or long-term agreements. However, balance these potential savings against inventory carrying costs and demand uncertainty. Consider partnering arrangements that provide pricing predictability while maintaining flexibility for volume fluctuations throughout product lifecycles.

Hidden Cost Analysis

Hidden costs can significantly impact SMT Assembly project profitability. Quality issues, schedule delays, and rework requirements often generate unexpected expenses that exceed initial cost projections. Evaluate potential partners based on their track records for on-time delivery, first-pass yield rates, and customer satisfaction metrics. Investing in higher-quality SMT Assembly services often provides better long-term value than selecting partners based solely on low initial pricing.

Transportation and logistics costs also affect total SMT Assembly expenses, particularly for international partnerships. Consider shipping methods, packaging requirements, customs procedures, and insurance costs when evaluating offshore providers. Domestic partnerships may offer advantages in communication, quality control, and supply chain security that offset higher labor costs in many applications.

Communication and Project Management

Collaboration Frameworks

Effective communication forms the foundation of successful SMT Assembly partnerships. Your chosen provider should demonstrate responsive communication practices, including dedicated project managers, regular status updates, and proactive issue escalation procedures. Look for partners who utilize collaborative tools and platforms that facilitate real-time information sharing and project visibility throughout the SMT Assembly process.

Design for manufacturability feedback represents a valuable service that distinguishes professional SMT Assembly providers. Experienced partners can identify potential manufacturing challenges early in the design process and suggest optimizations that improve yields, reduce costs, or enhance reliability. This collaborative approach helps prevent costly redesigns and accelerates time-to-market for new products requiring SMT Assembly services.

Documentation and Reporting

Comprehensive documentation supports quality control and regulatory compliance in SMT Assembly operations. Your partner should provide detailed assembly drawings, pick-and-place files, inspection reports, and certificate of conformance documentation. These materials facilitate design reviews, manufacturing audits, and customer approvals throughout product development and production phases.

Regular performance reporting enables continuous improvement in SMT Assembly partnerships. Look for providers who offer metrics tracking, trend analysis, and improvement recommendations based on production data. These insights help optimize processes, reduce costs, and enhance quality over time while building stronger collaborative relationships between your organizations.

FAQ

What certifications should I look for in an SMT Assembly partner?

Key certifications include ISO 9001 for quality management, IPC-A-610 for electronic assembly standards, and industry-specific certifications like AS9100 for aerospace applications or ISO 13485 for medical devices. These certifications demonstrate that the SMT Assembly provider maintains standardized processes, proper documentation, and continuous improvement practices that ensure consistent quality and regulatory compliance.

How do I evaluate the technical capabilities of SMT Assembly providers?

Assess their equipment capabilities, including pick-and-place machine specifications, component size ranges, and inspection systems. Review their experience with your specific component types, PCB complexities, and volume requirements. Request facility tours, capability demonstrations, and references from similar projects to verify their SMT Assembly expertise matches your technical requirements.

What factors should I consider when comparing SMT Assembly costs?

Evaluate total cost of ownership including setup fees, tooling costs, material handling charges, and potential hidden costs like rework or delays. Consider volume-based pricing structures, long-term agreement benefits, and transportation costs. Focus on value rather than lowest price, as quality issues and schedule delays in SMT Assembly can generate significant unexpected expenses.

How important is geographic location when selecting an SMT Assembly partner?

Location affects communication effectiveness, supply chain security, shipping costs, and quality control capabilities. Domestic SMT Assembly partners often provide advantages in responsiveness, intellectual property protection, and regulatory compliance, while offshore partners may offer cost benefits for high-volume applications. Consider your specific priorities regarding cost, quality, and risk tolerance when evaluating geographic options.