flex circuit board

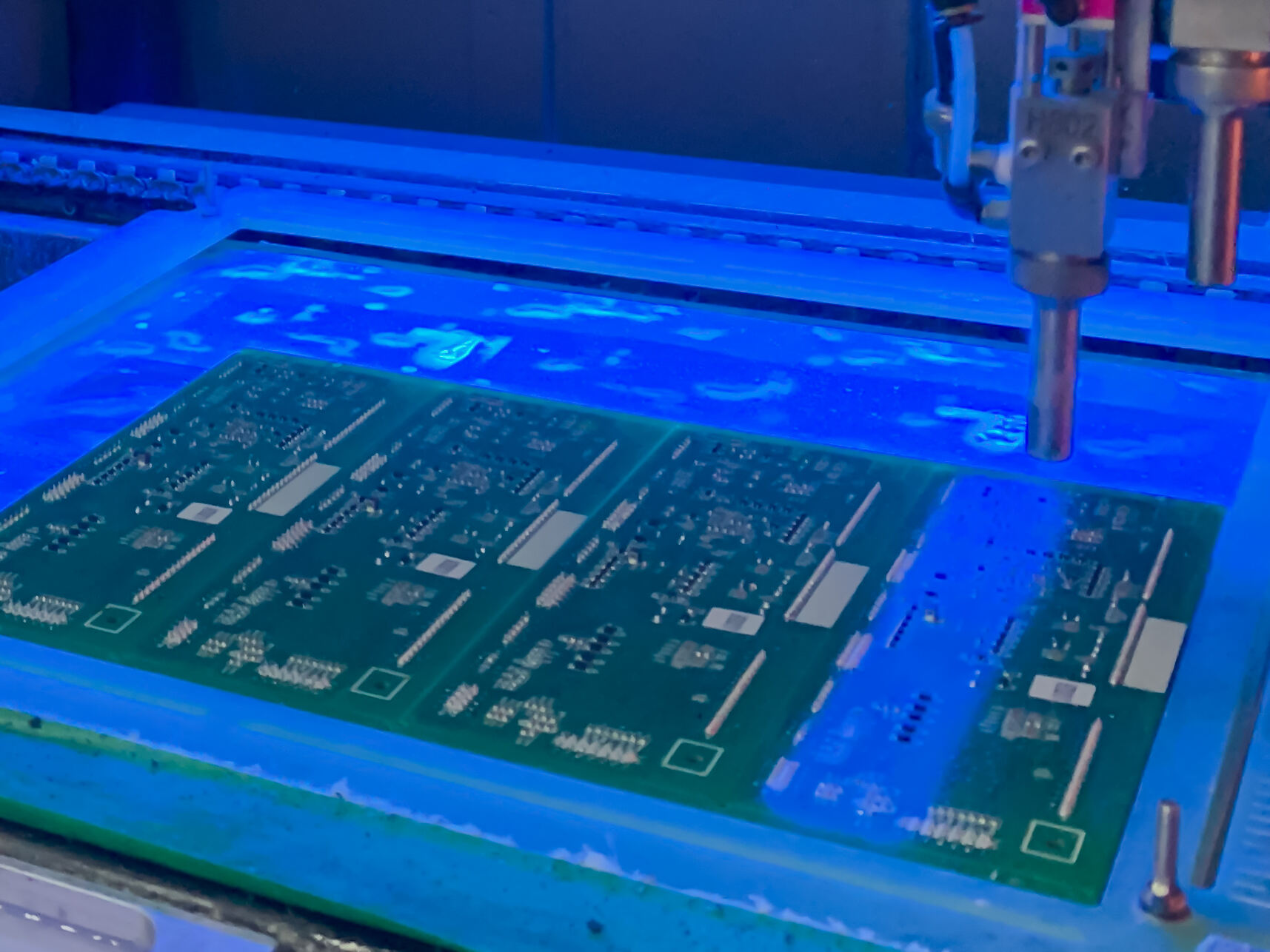

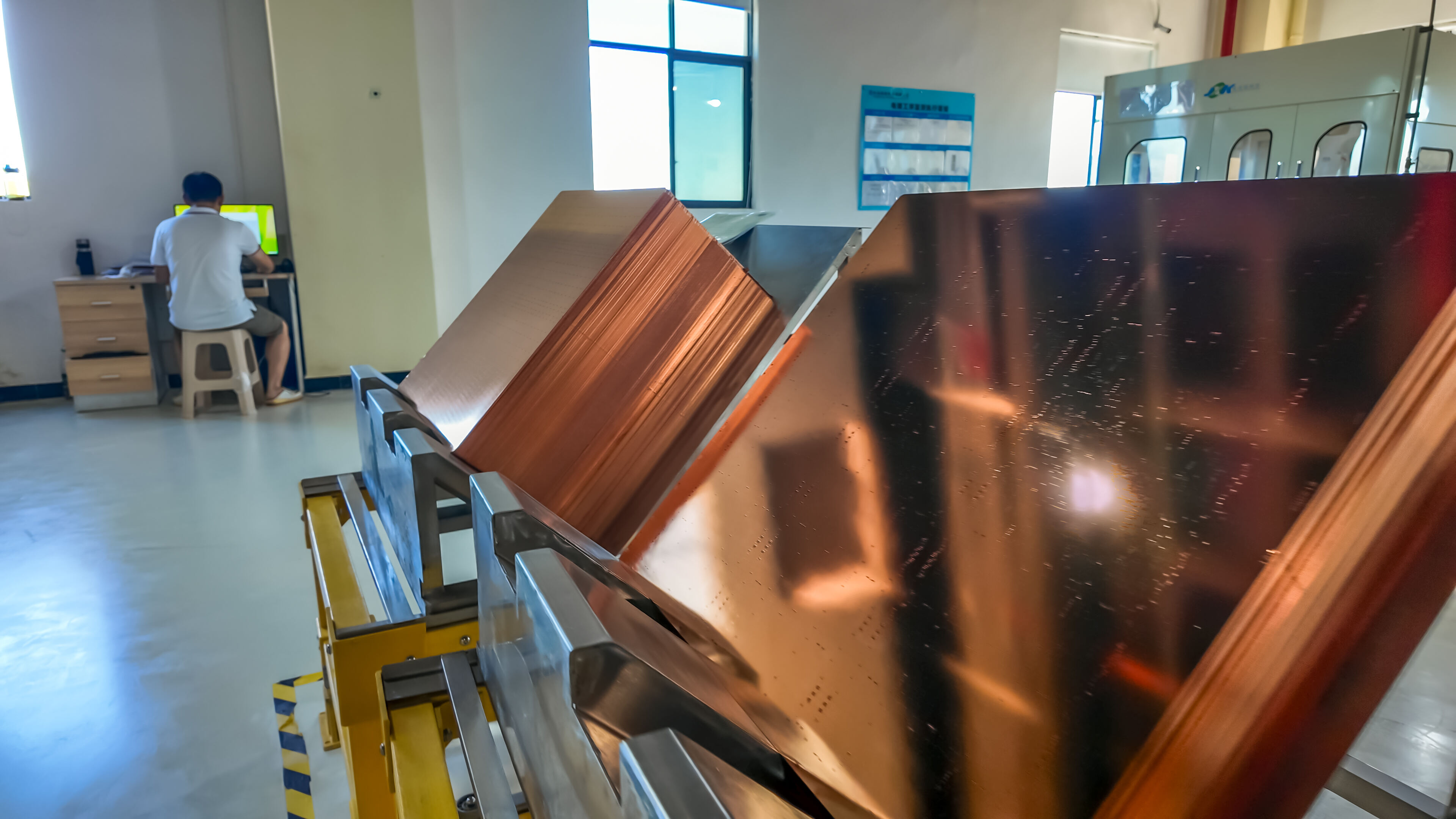

A flex circuit board, also known as a flexible printed circuit (FPC), represents a groundbreaking advancement in electronic design that combines the reliability of traditional printed circuit boards with the versatility of flexible materials. These innovative circuits are constructed using flexible base materials, typically polyimide or polyester films, which allow them to bend, fold, and conform to various shapes while maintaining full electrical functionality. The technology enables the creation of sophisticated electronic circuits that can be installed in spaces where rigid boards cannot fit, making them ideal for modern, compact electronic devices. Flex circuits can be designed in single-layer, double-layer, or multi-layer configurations, accommodating complex circuit requirements while maintaining minimal thickness. They excel in dynamic applications where the circuit must withstand repeated bending or flexing during operation, such as in printer heads, folding smartphones, or automotive dashboard displays. The manufacturing process involves precision layering of conductive materials onto the flexible substrate, followed by specialized techniques for component mounting and protection. These boards have revolutionized electronic design by enabling three-dimensional electronic packaging solutions, reducing assembly costs, and improving reliability through the elimination of mechanical connectors and wire harnesses.