The Evolution of PCB Solutions in Modern Industrial Landscapes

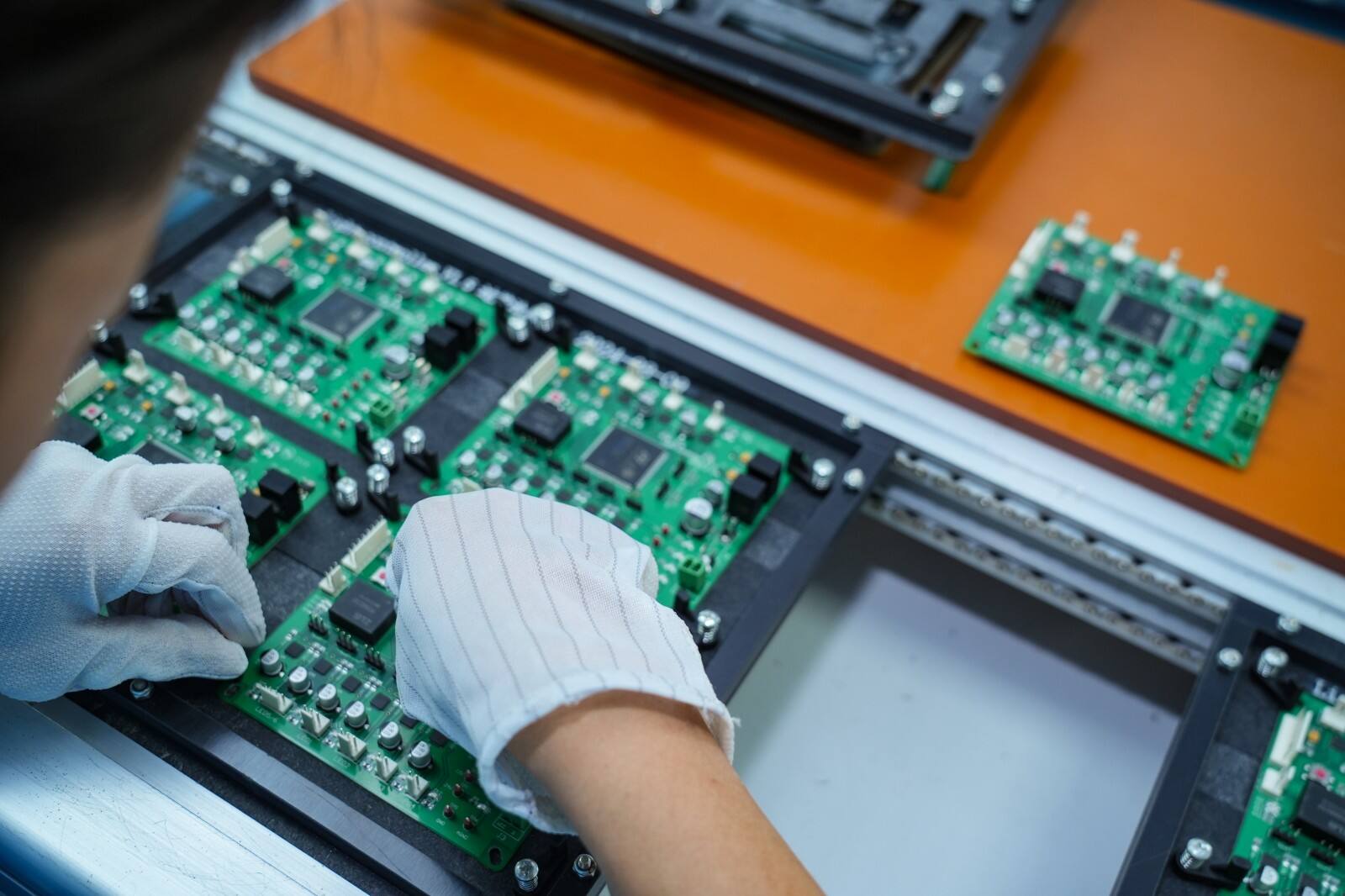

The industrial sector has witnessed a remarkable transformation with the integration of advanced PCB solutions into its core operations. From automated manufacturing facilities to sophisticated control systems, printed circuit boards have become the backbone of industrial innovation. These essential components drive efficiency, reliability, and precision across diverse applications, fundamentally reshaping how industries operate in the digital age.

As manufacturing demands grow increasingly complex, the role of PCB solutions has expanded beyond simple circuit connectivity. Today's industrial applications require robust, high-performance boards that can withstand harsh environments while delivering consistent results. This evolution reflects the industry's push toward smarter, more connected operations that optimize productivity and reduce downtime.

Key Benefits of Industrial PCB Solutions

Enhanced Durability and Reliability

Industrial PCB solutions are engineered to excel in demanding environments where consumer-grade alternatives would quickly fail. These boards feature specialized materials and construction techniques that resist temperature extremes, vibration, and chemical exposure. The enhanced durability translates to longer operational lifespans and reduced maintenance requirements, making them ideal for critical industrial applications.

Furthermore, industrial-grade PCBs undergo rigorous testing and quality control measures to ensure consistent performance under stress. This reliability is essential in manufacturing environments where equipment failure can result in costly production delays and compromised safety standards.

Advanced Performance Capabilities

Modern industrial PCB solutions incorporate cutting-edge design features that optimize performance across various applications. Multi-layer configurations allow for complex circuit designs while maintaining compact form factors. High-speed signal integrity and superior electromagnetic compatibility ensure smooth operation even in electrically noisy industrial environments.

The integration of advanced materials and manufacturing techniques enables these boards to handle higher power requirements and faster data processing speeds. This enhanced capability supports the growing demands of Industry 4.0 technologies, including real-time monitoring systems and automated control processes.

Design Considerations for Industrial Applications

Material Selection and Thermal Management

Choosing the right materials for industrial PCB solutions is crucial for long-term success. High-temperature substrates, such as polyimide and ceramic-based materials, provide excellent thermal stability and mechanical strength. These materials ensure reliable operation in environments where standard FR-4 boards would degrade rapidly.

Effective thermal management strategies, including copper heat sinks and thermal vias, help dissipate heat efficiently. This consideration is particularly important in industrial applications where components operate continuously under heavy loads.

Layout and Component Placement

Industrial PCB design requires careful attention to component placement and trace routing. Strategic layout decisions minimize electromagnetic interference while optimizing signal integrity. Adequate spacing between components facilitates heat dissipation and simplifies maintenance procedures when necessary.

The implementation of proper grounding schemes and power distribution networks ensures stable operation under varying load conditions. These design elements are essential for maintaining signal quality and preventing operational issues in industrial environments.

Implementation Strategies for Maximum Efficiency

Integration with Existing Systems

Successful deployment of industrial PCB solutions requires seamless integration with existing infrastructure. This process involves careful planning to ensure compatibility with legacy systems while providing pathways for future upgrades. Standardized interfaces and modular designs facilitate this integration, reducing downtime during implementation.

Companies must consider both hardware and software compatibility when implementing new PCB solutions. This holistic approach ensures smooth operation and maximizes the benefits of upgraded systems.

Maintenance and Monitoring Protocols

Establishing comprehensive maintenance protocols is essential for maximizing the lifespan of industrial PCB solutions. Regular inspections, preventive maintenance schedules, and monitoring systems help identify potential issues before they impact production. This proactive approach minimizes unexpected downtime and extends equipment service life.

Modern PCB solutions often incorporate built-in diagnostic capabilities that facilitate predictive maintenance. These features allow maintenance teams to monitor board performance and schedule interventions based on actual operating conditions rather than fixed time intervals.

Future Trends in Industrial PCB Solutions

Smart Manufacturing Integration

The future of industrial PCB solutions lies in their increasing integration with smart manufacturing systems. Advanced boards featuring embedded sensors and connectivity options enable real-time monitoring and control capabilities. This evolution supports the industry's movement toward fully automated and interconnected production environments.

As Industrial IoT continues to expand, PCB solutions will play a crucial role in enabling seamless communication between different systems and devices. This connectivity drives improvements in efficiency, quality control, and overall operational intelligence.

Sustainable Design and Manufacturing

Environmental considerations are becoming increasingly important in industrial PCB design and manufacturing. Future solutions will emphasize sustainable materials and energy-efficient designs while maintaining high performance standards. This trend reflects growing industry awareness of environmental responsibility and regulatory requirements.

Innovations in recycling technologies and green manufacturing processes are shaping the development of next-generation PCB solutions. These advances promise to reduce environmental impact while delivering the reliability and performance industrial applications demand.

Frequently Asked Questions

What makes industrial PCB solutions different from standard PCBs?

Industrial PCB solutions are specifically designed to withstand harsh environments, featuring superior materials, enhanced durability, and advanced thermal management capabilities. They undergo more rigorous testing and quality control measures to ensure reliable performance in demanding industrial applications.

How long do industrial PCB solutions typically last?

The lifespan of industrial PCB solutions varies depending on operating conditions and maintenance practices, but they are typically designed to last 10-15 years or more. With proper maintenance and protection from environmental stresses, many industrial PCBs can exceed their expected service life.

Can industrial PCB solutions be customized for specific applications?

Yes, industrial PCB solutions can be highly customized to meet specific application requirements. This includes modifications to board layout, component selection, material choices, and environmental protection measures to ensure optimal performance in particular industrial settings.

What maintenance is required for industrial PCB solutions?

Regular maintenance includes visual inspections, cleaning, connection testing, and performance monitoring. Preventive maintenance schedules should be established based on operating conditions and manufacturer recommendations to ensure optimal performance and longevity.