Understanding Common PCB Circuit Board Issues and Their Solutions

PCB circuit boards are the backbone of modern electronics, serving as the foundation for countless devices we use daily. From smartphones to industrial machinery, these intricate components play a crucial role in ensuring proper device functionality. However, like any sophisticated technology, PCB circuit boards can experience various problems that affect their performance and reliability. Understanding these issues and knowing how to address them is essential for electronics manufacturers, engineers, and maintenance professionals.

The complexity of PCB circuit boards has increased significantly over the years, making them more susceptible to various manufacturing defects and operational problems. As electronics continue to shrink in size while growing in functionality, the demands placed on PCB circuit boards have become more challenging. This comprehensive guide explores the most common issues that affect these vital components and provides practical solutions to maintain their optimal performance.

Manufacturing-Related PCB Defects

Copper Trace Problems and Solutions

One of the most frequent manufacturing defects in PCB circuit boards involves copper traces. These conductive pathways can suffer from various issues, including breaks, shorts, and improper spacing. When copper traces are too thin or improperly etched, they may break under thermal stress or mechanical strain. Additionally, insufficient spacing between traces can lead to short circuits, especially in high-voltage applications.

To address copper trace problems, manufacturers must implement strict quality control measures during the fabrication process. This includes utilizing precise etching techniques, maintaining proper copper thickness, and ensuring adequate spacing between traces. Regular inspection using automated optical inspection (AOI) systems can help identify potential trace issues before they become critical failures.

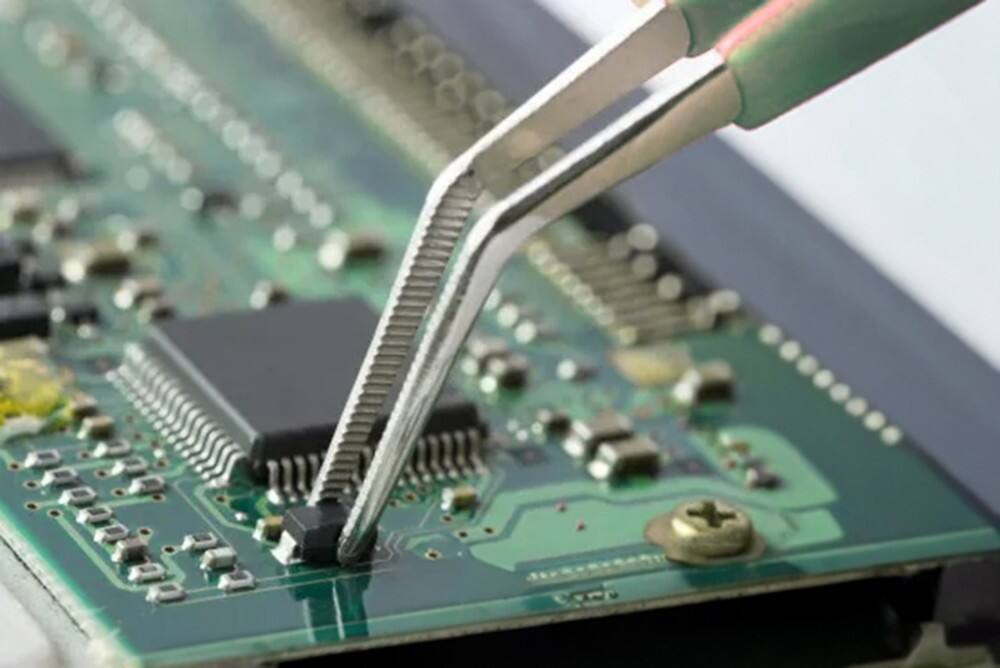

Solder Joint Defects

Solder joint problems represent another significant category of PCB circuit board defects. Cold solder joints, excessive solder, and insufficient solder can all compromise the board's reliability. These issues often stem from improper temperature control during the soldering process or inadequate surface preparation.

Implementing proper soldering techniques and maintaining precise temperature control during assembly are essential for preventing solder joint defects. Using advanced reflow ovens with multiple heating zones and careful control of solder paste quantity can significantly reduce these issues. Regular inspection and testing of solder joints using X-ray systems can help identify potential problems early in the manufacturing process.

Environmental Impact on PCB Performance

Moisture and Humidity Effects

PCB circuit boards are particularly susceptible to moisture-related problems. High humidity environments can lead to corrosion of metal components, delamination of board layers, and electrical shorts. When moisture becomes trapped within the board material, it can cause significant damage during the high-temperature soldering process.

Protecting PCB circuit boards from moisture requires proper storage conditions and handling procedures. Using moisture-barrier bags, maintaining appropriate humidity levels in storage areas, and implementing proper baking procedures before assembly can help prevent moisture-related issues. Additionally, applying conformal coatings can provide long-term protection against environmental moisture.

Temperature-Related Challenges

Extreme temperatures and thermal cycling can cause various problems in PCB circuit boards. These include component desoldering, thermal stress cracks, and warpage of the board material. Temperature variations can also lead to differential expansion between components and the board, potentially causing connection failures.

To mitigate temperature-related issues, careful consideration must be given to thermal management during both design and operation. This includes proper component spacing, the use of thermal relief pads, and implementation of adequate cooling solutions. Advanced thermal simulation tools can help predict potential hot spots and guide design modifications to improve thermal performance.

Electrical Performance Issues

Signal Integrity Problems

Signal integrity issues are becoming increasingly common as PCB circuit boards operate at higher frequencies and speeds. Cross-talk between adjacent traces, electromagnetic interference (EMI), and signal reflections can all degrade performance and cause operational problems.

Addressing signal integrity requires careful attention to PCB layout and design rules. This includes proper trace routing, controlled impedance design, and appropriate use of ground planes. Advanced signal integrity analysis tools can help identify potential problems during the design phase, allowing for corrections before manufacturing.

Power Distribution Challenges

Proper power distribution is critical for PCB circuit board performance. Voltage drops, ground bounce, and power plane resonance can all affect the reliable operation of electronic devices. These issues become more pronounced in high-power and high-speed applications.

Implementing proper power distribution network (PDN) design techniques is essential for preventing power-related problems. This includes using adequate copper weight for power planes, proper decoupling capacitor placement, and careful consideration of current return paths. Advanced PDN analysis tools can help optimize power delivery and identify potential issues during the design phase.

Maintenance and Troubleshooting Strategies

Regular Inspection Procedures

Implementing a systematic approach to PCB circuit board inspection can help identify potential problems before they cause device failures. This includes visual inspection for physical damage, thermal imaging to identify hot spots, and electrical testing to verify proper functionality.

Regular maintenance schedules should include cleaning procedures to remove dust and debris, inspection of solder joints and components, and verification of proper mounting and mechanical stability. Documentation of inspection results and maintenance activities helps track recurring issues and identify trends that may indicate systemic problems.

Advanced Diagnostic Techniques

Modern diagnostic tools and techniques provide powerful capabilities for troubleshooting PCB circuit board problems. These include boundary scan testing, in-circuit testing, and flying probe systems that can identify both manufacturing defects and operational issues.

Investing in appropriate test equipment and training personnel in their use is essential for effective troubleshooting. Developing systematic diagnostic procedures and maintaining detailed documentation of test results helps ensure consistent and efficient problem resolution.

Frequently Asked Questions

How can I prevent moisture damage to PCB circuit boards?

To prevent moisture damage, store PCB circuit boards in moisture-barrier bags with desiccant packets, maintain proper humidity levels in storage areas, and implement appropriate baking procedures before assembly. Using conformal coatings can provide additional protection against environmental moisture.

What are the signs of thermal stress in PCB circuit boards?

Common signs of thermal stress include discolored or darkened areas on the board, warped or deformed sections, cracked solder joints, and lifted pads or traces. Regular thermal imaging can help identify potential hot spots before they cause damage.

How often should PCB circuit boards be inspected?

The frequency of PCB circuit board inspections depends on the application and operating environment. Critical applications may require daily or weekly inspections, while less demanding applications might need only quarterly or annual inspections. Regular monitoring of performance metrics can help determine appropriate inspection intervals.