The Critical Role of Expert PCB Production in Modern Electronics

In today's rapidly evolving electronics industry, the quality and reliability of printed circuit boards (PCBs) have become more crucial than ever. Professional PCB manufacturing services represent the backbone of electronic device production, ensuring that everything from smartphones to industrial equipment functions flawlessly. As technology advances and devices become increasingly complex, the expertise required to produce high-quality PCBs has reached new heights.

The electronics manufacturing landscape has transformed dramatically over the past decade, with PCB manufacturing services adapting to meet increasingly stringent requirements. Whether it's the demand for smaller form factors, higher component density, or enhanced performance specifications, professional manufacturers have continuously evolved their capabilities to stay ahead of industry needs.

Advanced Manufacturing Capabilities and Technology

State-of-the-Art Equipment and Processes

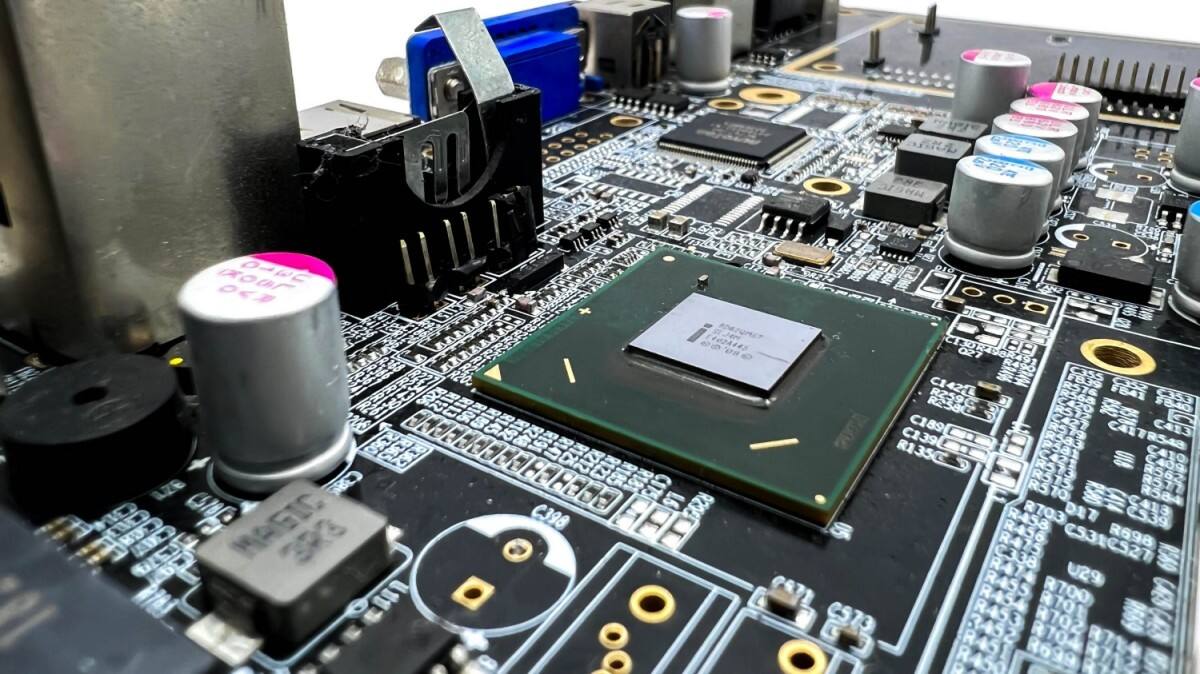

Professional PCB manufacturing services utilize cutting-edge equipment and advanced manufacturing processes to ensure superior quality and precision. These facilities employ automated optical inspection (AOI) systems, X-ray inspection equipment, and sophisticated testing apparatus to maintain exceptional quality standards throughout the production process.

Modern PCB manufacturing facilities feature climate-controlled clean rooms, advanced lamination systems, and precise chemical processing equipment. This sophisticated infrastructure enables manufacturers to produce multi-layer boards with exceptional accuracy and reliability, meeting the most demanding specifications of contemporary electronic devices.

Quality Control and Testing Protocols

Leading PCB manufacturing services implement comprehensive quality control measures at every production stage. From initial design verification to final testing, each board undergoes rigorous inspection and testing procedures. These include electrical testing, impedance testing, and thermal stress analysis to ensure optimal performance under various operating conditions.

The implementation of automated testing systems helps identify potential issues before boards leave the facility, significantly reducing the likelihood of field failures. This proactive approach to quality assurance has become a hallmark of professional PCB manufacturing services, setting them apart from less sophisticated alternatives.

Design Support and Engineering Expertise

Collaborative Design Optimization

Professional PCB manufacturing services often provide valuable design support and optimization recommendations. Their engineering teams possess extensive experience in design for manufacturing (DFM) and design for testing (DFT) principles, helping clients optimize their designs for improved manufacturability and reliability.

Through collaborative engagement with clients, these services can identify potential design issues early in the development process, suggesting modifications that enhance production efficiency while maintaining design integrity. This expertise often proves invaluable in reducing time-to-market and overall production costs.

Technical Documentation and Support

Expert PCB manufacturing services maintain detailed documentation of all manufacturing processes and specifications. This comprehensive approach includes maintaining revision histories, component libraries, and manufacturing notes that ensure consistency across production runs and facilitate future modifications or updates.

The availability of technical support throughout the manufacturing process provides clients with peace of mind and quick resolution of any concerns that may arise. This level of support is particularly valuable for complex designs or when specific regulatory requirements must be met.

Industry Compliance and Certification

Regulatory Standards and Certifications

Professional PCB manufacturing services maintain various industry certifications and comply with international standards. These typically include ISO 9001 certification for quality management systems, ISO 14001 for environmental management, and specific industry standards such as IPC-A-600 for PCB acceptability.

Adherence to these standards ensures that manufactured PCBs meet or exceed industry requirements for quality, reliability, and environmental responsibility. This commitment to compliance provides clients with confidence in the finished product and helps meet end-product certification requirements.

Environmental and Safety Considerations

Modern PCB manufacturing services prioritize environmental responsibility and worker safety. This includes implementing proper handling and disposal of chemicals, reducing waste through efficient processes, and maintaining safe working conditions for all personnel.

Many facilities now offer lead-free manufacturing options and comply with RoHS (Restriction of Hazardous Substances) directives, meeting global environmental standards while maintaining high-quality output. This commitment to sustainability has become increasingly important as environmental consciousness grows within the electronics industry.

Cost-Effectiveness and Production Efficiency

Economies of Scale and Resource Optimization

Professional PCB manufacturing services achieve cost efficiencies through optimized production processes and economies of scale. By maintaining high-volume capabilities while offering flexibility for smaller runs, these services can provide competitive pricing without compromising quality.

Advanced resource management systems and efficient production planning help minimize waste and optimize material usage, resulting in cost savings that can be passed on to clients. This efficiency extends to reduced lead times and improved delivery reliability.

Long-term Cost Benefits

While professional PCB manufacturing services may initially appear more expensive than budget alternatives, the long-term benefits often result in significant cost savings. Higher quality production means fewer field failures, reduced warranty claims, and improved end-product reliability.

The ability to consistently produce high-quality PCBs also helps maintain brand reputation and customer satisfaction, contributing to long-term business success. Professional manufacturers' expertise in handling complex designs and specifications often results in fewer revision cycles and faster time-to-market.

Frequently Asked Questions

What turnaround times can be expected from professional PCB manufacturing services?

Professional PCB manufacturing services typically offer various turnaround options ranging from standard production times of 5-10 business days to expedited services as quick as 24-48 hours. The exact timing depends on factors such as board complexity, quantity, and specific requirements.

How do professional PCB manufacturers ensure quality control?

Professional manufacturers implement multiple quality control measures including automated optical inspection, electrical testing, impedance testing, and X-ray inspection for multi-layer boards. They also maintain strict process controls and documentation throughout the manufacturing process.

What minimum order quantities do professional PCB manufacturers typically accept?

Many professional PCB manufacturing services offer flexible order quantities, from prototype runs of just a few boards to high-volume production runs of thousands. While pricing may vary based on quantity, reputable manufacturers can accommodate various production volumes to meet different client needs.