pcb rigid

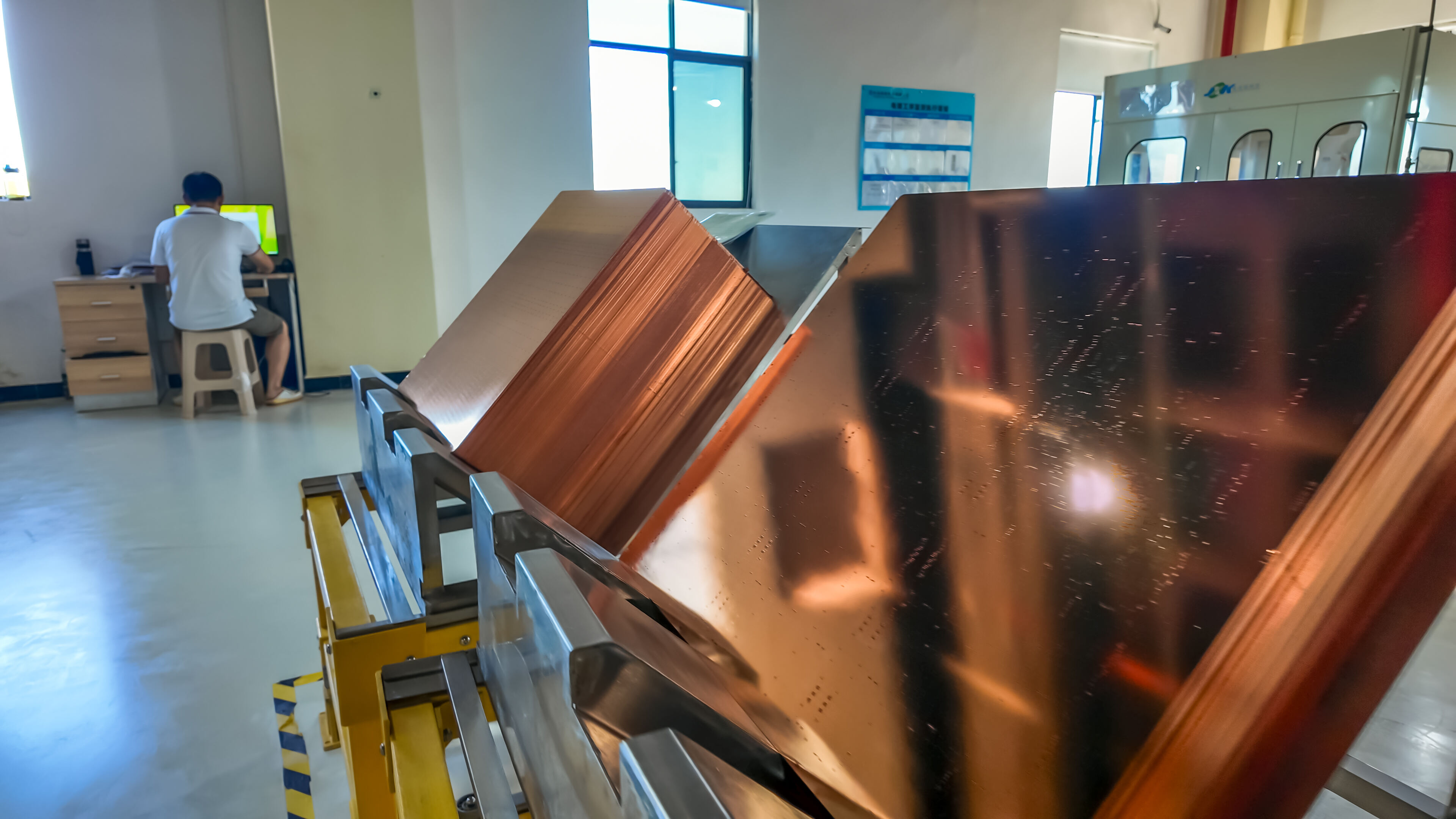

A PCB rigid, or rigid printed circuit board, represents a fundamental component in modern electronics manufacturing, serving as a robust platform for mounting and interconnecting electronic components. These boards are constructed from multiple layers of materials, typically including a non-conductive substrate made from FR4 glass-reinforced epoxy laminate material, conductive copper layers, and protective solder mask coating. The rigid nature of these boards provides exceptional mechanical stability and reliability, making them ideal for applications where structural integrity is paramount. PCB rigids feature precisely etched conductive pathways that facilitate electrical connections between components, while their multi-layer capability allows for complex circuit designs in a compact form factor. The manufacturing process involves sophisticated techniques including photolithography, etching, and automated assembly, ensuring consistent quality and performance. These boards are extensively used across various industries, from consumer electronics and automotive applications to medical devices and aerospace equipment, where their durability and reliability are essential. The standardized manufacturing process enables mass production while maintaining high quality standards, making PCB rigids a cost-effective solution for electronic device manufacturing.