pcb circuit board manufacturers

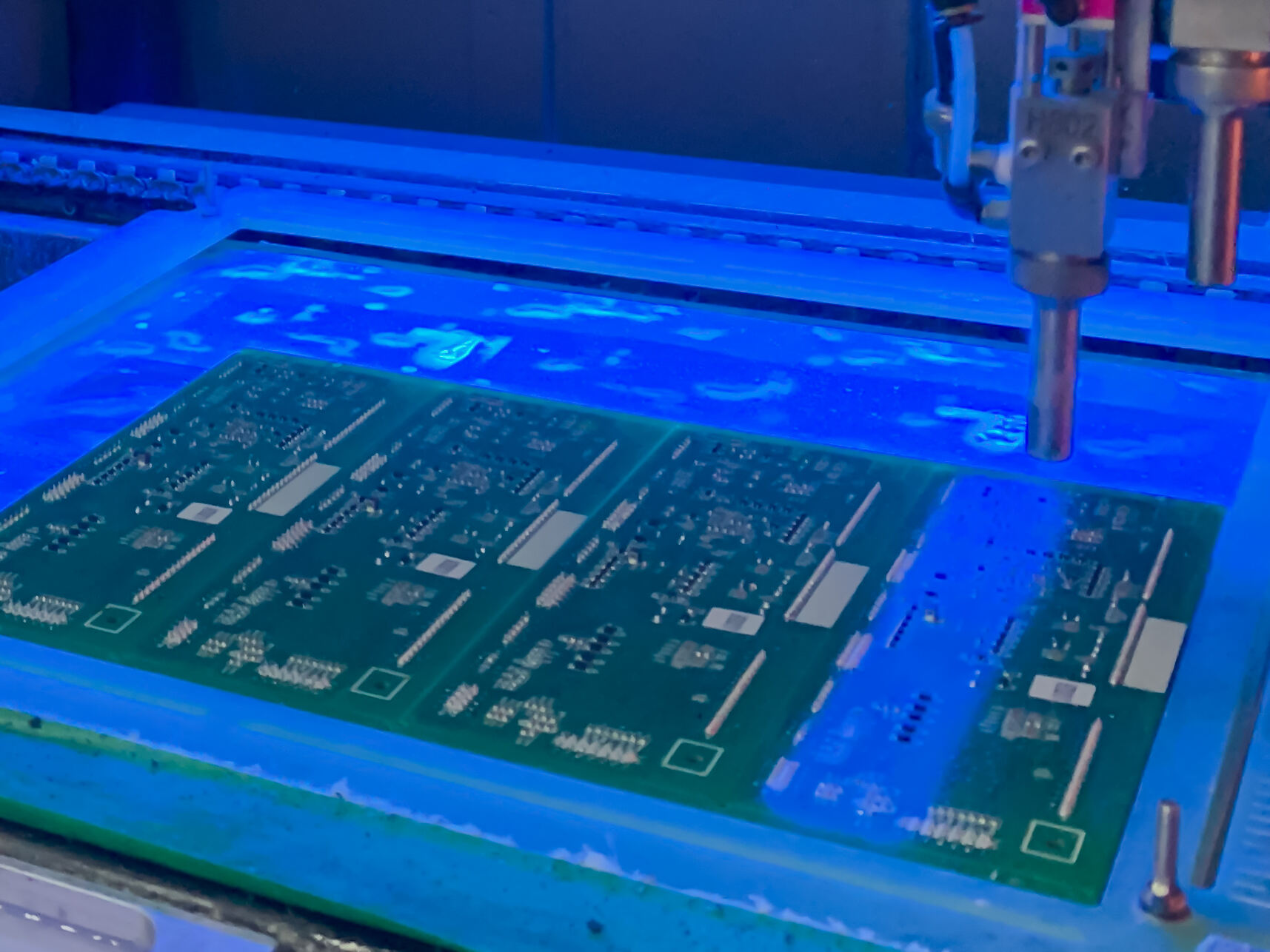

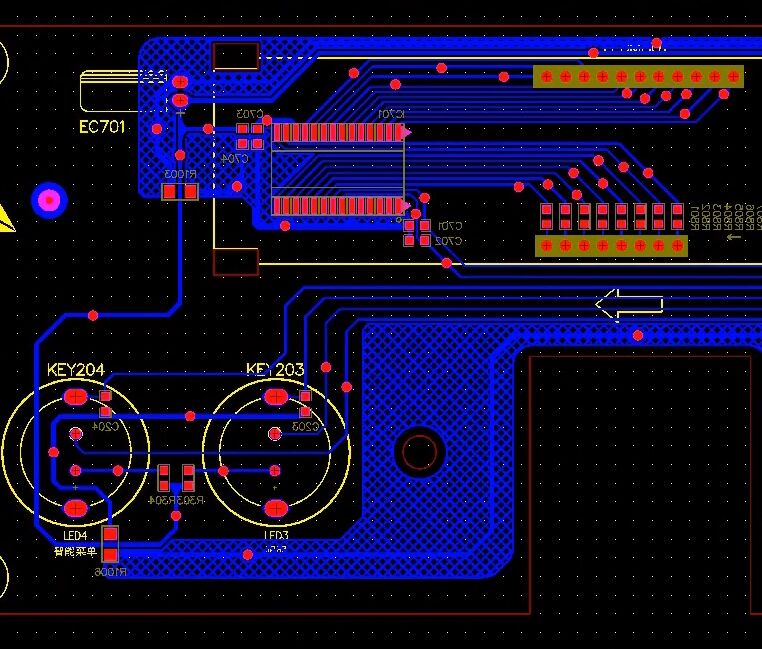

PCB circuit board manufacturers are specialized companies that design, produce, and assemble printed circuit boards, which serve as the foundation for modern electronic devices. These manufacturers employ state-of-the-art technology and precision engineering to create multilayer circuit boards that connect various electronic components. They utilize advanced manufacturing processes, including photolithography, etching, and automated assembly lines, to ensure consistent quality and reliability. These facilities are equipped with surface mount technology (SMT) machines, automated optical inspection systems, and testing equipment to maintain high production standards. Modern PCB manufacturers offer services ranging from prototype development to mass production, accommodating both simple single-layer boards and complex multilayer designs. They implement strict quality control measures, following international standards such as ISO 9001, and often provide additional services like component sourcing, design optimization, and technical support. Many manufacturers also offer specialized services such as flex and rigid-flex PCB production, high-frequency board manufacturing, and thermal management solutions. Their capabilities extend to various industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics.