aluminium circuit board

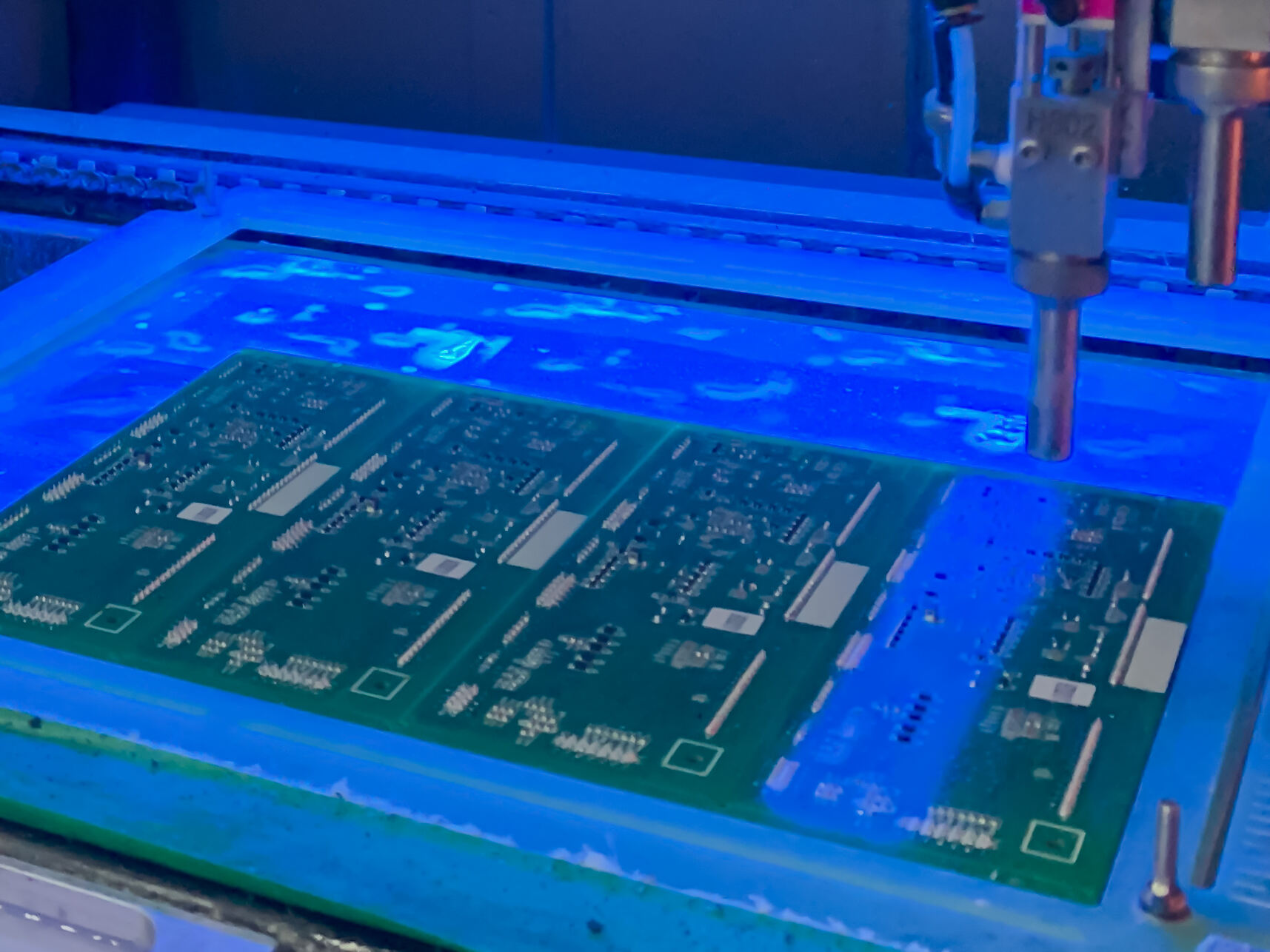

Aluminum circuit boards represent a significant advancement in electronic component manufacturing, combining the excellent thermal properties of aluminum with sophisticated circuit design capabilities. These specialized PCBs feature a metal base layer made of aluminum, which serves as both a structural support and a highly efficient heat dissipation mechanism. The construction typically consists of three main layers: an aluminum base layer, a thermally conductive dielectric layer, and a copper circuit layer. This innovative design allows for superior heat management compared to traditional FR4 circuit boards, making them particularly valuable in high-power applications. The aluminum substrate, typically ranging from 1.0mm to 3.0mm in thickness, provides exceptional thermal conductivity while maintaining structural integrity. These circuit boards are engineered to handle thermal conductivity rates up to 380W/mk, significantly outperforming conventional PCB materials. The integration of aluminum as the base material also enables these boards to operate efficiently in challenging environments where heat management is crucial. They find extensive applications in LED lighting systems, power supplies, automotive electronics, and high-performance computing devices where thermal management is paramount.