alu pcb

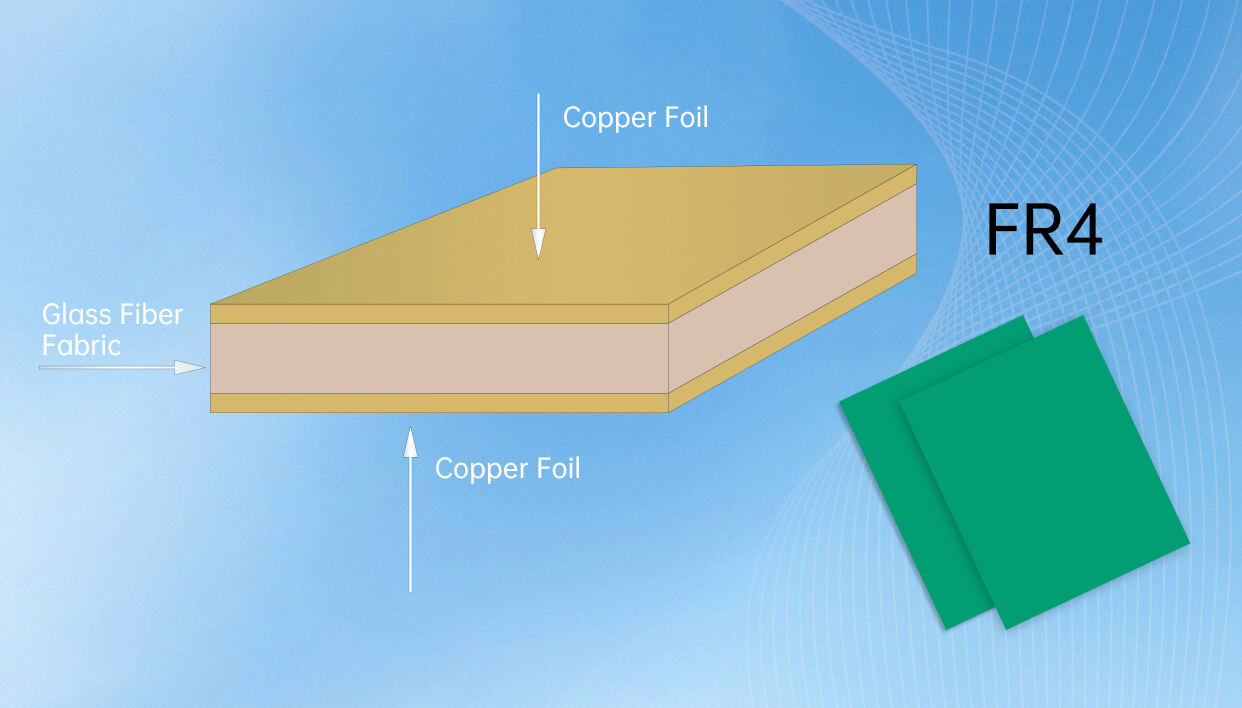

Aluminum PCB (alu PCB) represents a cutting-edge solution in electronic circuit board technology, combining the durability of aluminum with advanced thermal management capabilities. These specialized circuit boards feature a metal base substrate, typically aluminum, which serves as both a structural support and an efficient heat dissipator. The construction consists of three essential layers: a thermally conductive dielectric layer, a circuit layer, and an aluminum base. This unique composition enables superior heat dissipation compared to traditional FR4 PCBs, making them ideal for high-power applications. Alu PCBs excel in applications requiring efficient thermal management, such as LED lighting systems, power supplies, and automotive electronics. The aluminum base, typically ranging from 1.0mm to 3.0mm in thickness, provides excellent mechanical strength while maintaining good thermal conductivity. These PCBs can effectively handle temperatures up to 150°C and offer thermal conductivity rates of 1.0 to 3.0 W/m.K, making them essential for modern electronic devices that generate significant heat during operation.