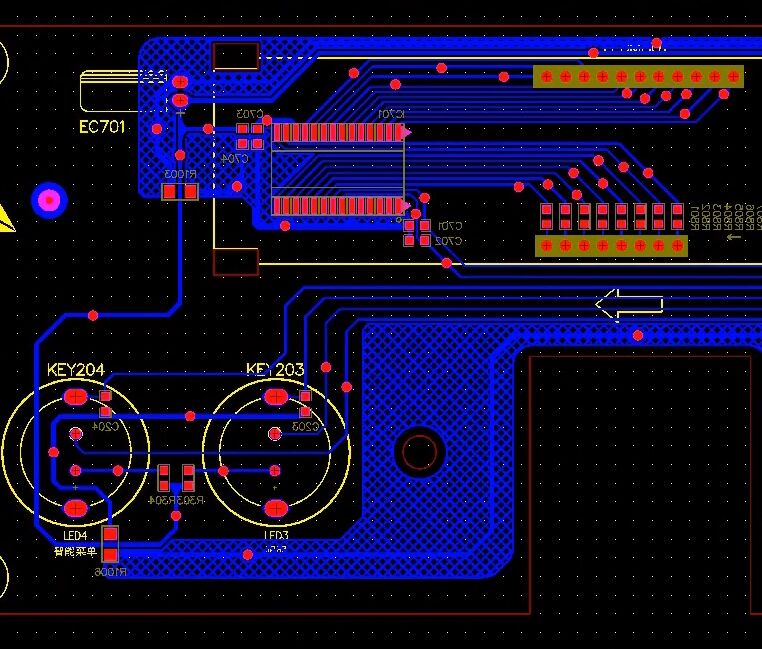

ceramic pcb board

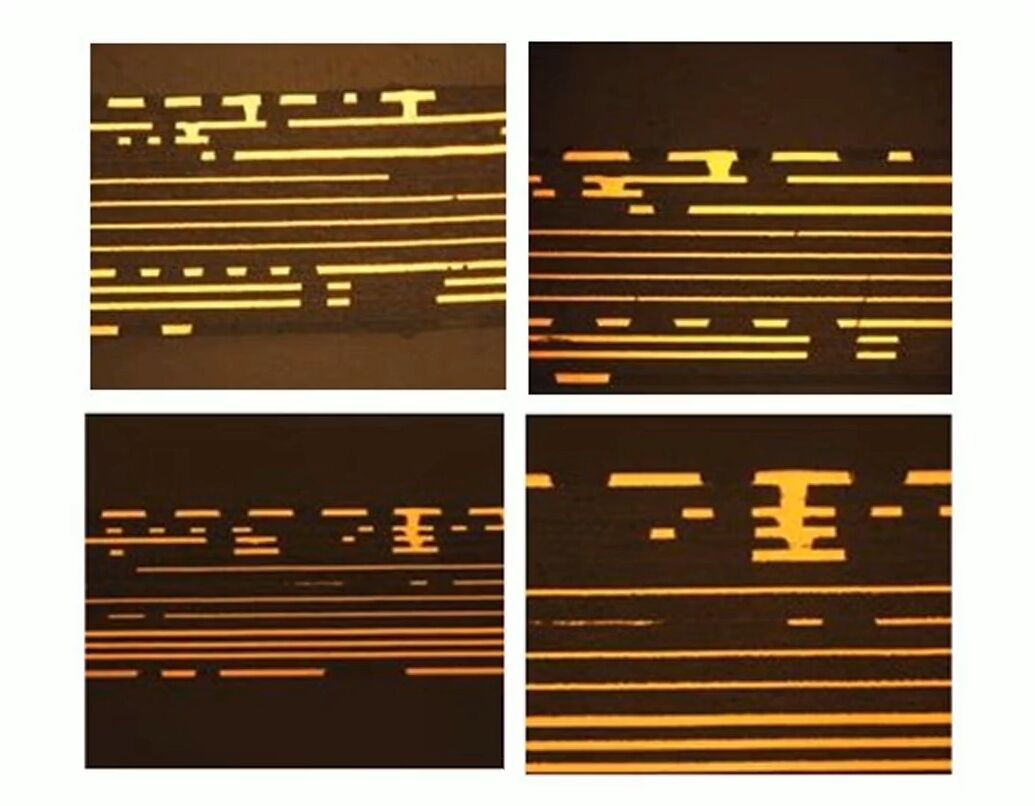

A ceramic PCB board represents a cutting-edge solution in electronic circuit manufacturing, specifically designed to operate in extreme conditions where traditional FR4 boards would fail. These specialized boards utilize ceramic materials as the base substrate, typically aluminum oxide or aluminum nitride, providing exceptional thermal conductivity and stability. The ceramic substrate enables superior heat dissipation, making it ideal for high-power applications and devices operating at elevated temperatures. These boards feature excellent dimensional stability, maintaining their structural integrity even under intense thermal stress. The ceramic material's inherent properties allow for precise circuit patterns and enhanced signal integrity, particularly crucial in high-frequency applications. The boards can withstand temperatures exceeding 300°C, making them essential in automotive, aerospace, and industrial applications where reliability under extreme conditions is paramount. Their low thermal expansion coefficient ensures component stability, while their hermetic properties provide excellent protection against moisture and corrosive environments. The ceramic construction also enables miniaturization of electronic components while maintaining optimal thermal management, crucial for modern compact electronic devices.