bendable circuit board

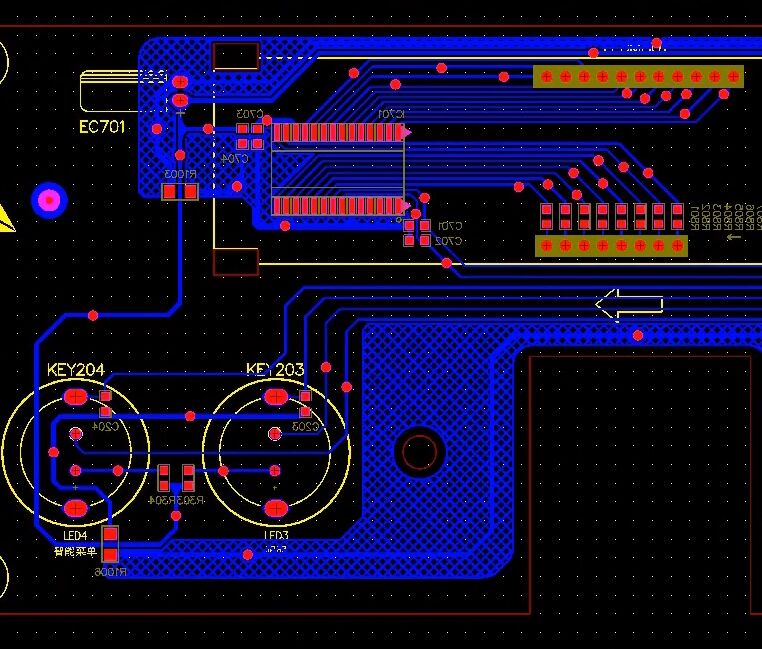

A bendable circuit board, also known as a flexible printed circuit (FPC), represents a groundbreaking advancement in electronic component design and manufacturing. These innovative circuits are constructed using flexible base materials and conductive layers that can be bent, folded, and twisted while maintaining their electrical functionality. The primary construction consists of a flexible polymer film base material, typically polyimide or polyester, combined with conductive copper layers and protective coatings. These circuits can be designed in single-sided, double-sided, or multilayer configurations, offering various levels of complexity and functionality. The flexibility of these circuits allows them to fit into tight spaces, conform to irregular shapes, and withstand dynamic applications where traditional rigid circuit boards would fail. They excel in applications requiring movement, vibration resistance, and space optimization. The technology behind bendable circuit boards has evolved significantly, incorporating advanced materials and manufacturing processes that ensure reliability while maintaining flexibility. These circuits are widely used in modern electronic devices, from smartphones and laptops to medical devices and automotive systems, where space constraints and design flexibility are crucial considerations.