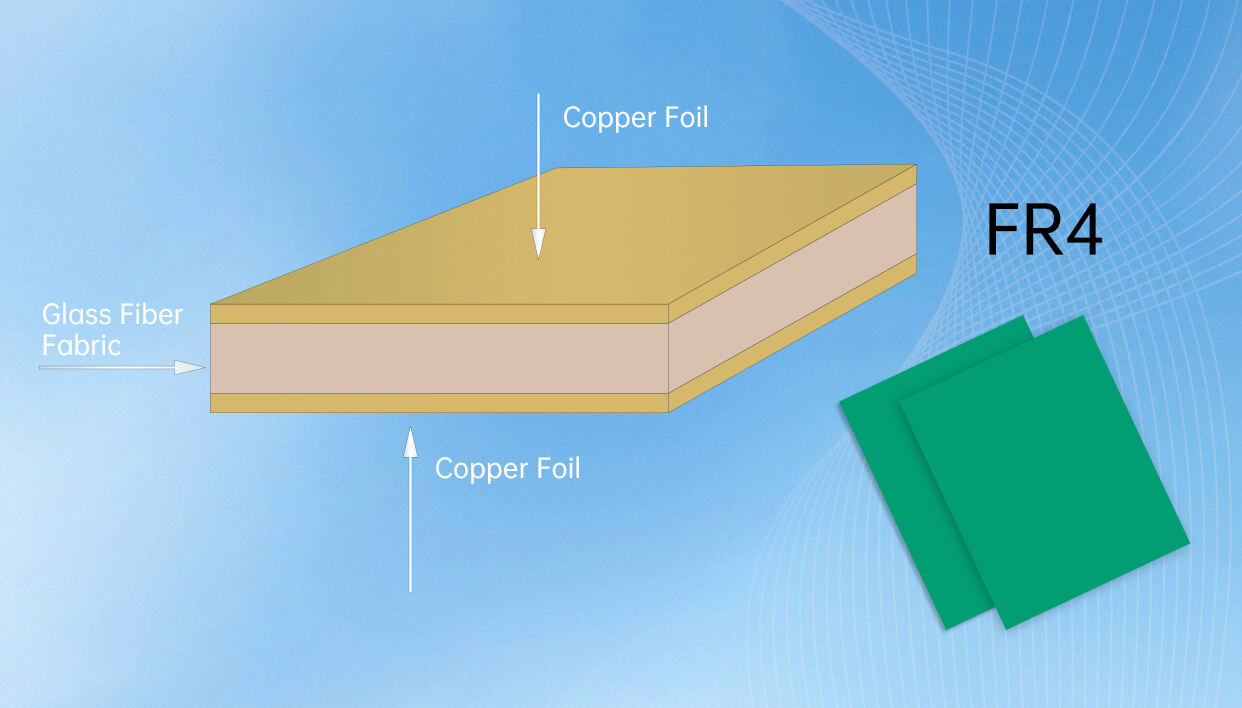

pcb circuit board material

PCB circuit board material serves as the foundation for modern electronics, comprising multiple layers of specialized substrates that enable the intricate routing of electrical signals. The most common base material is FR4, a composite of woven fiberglass cloth impregnated with epoxy resin, providing excellent electrical insulation and mechanical strength. These materials are engineered to maintain stability across varying temperatures and environmental conditions, ensuring reliable performance in diverse applications. The substrate features copper layers that are precisely etched to create conductive pathways, while the dielectric materials between layers prevent unwanted signal interference. Advanced PCB materials incorporate specialized additives to enhance thermal management, reduce signal loss, and improve overall reliability. Modern PCB materials also support high-frequency applications, with controlled impedance characteristics essential for today's high-speed digital devices. The material selection process considers factors such as thermal expansion, dielectric constant, and glass transition temperature, ensuring optimal performance in specific applications ranging from consumer electronics to aerospace systems.