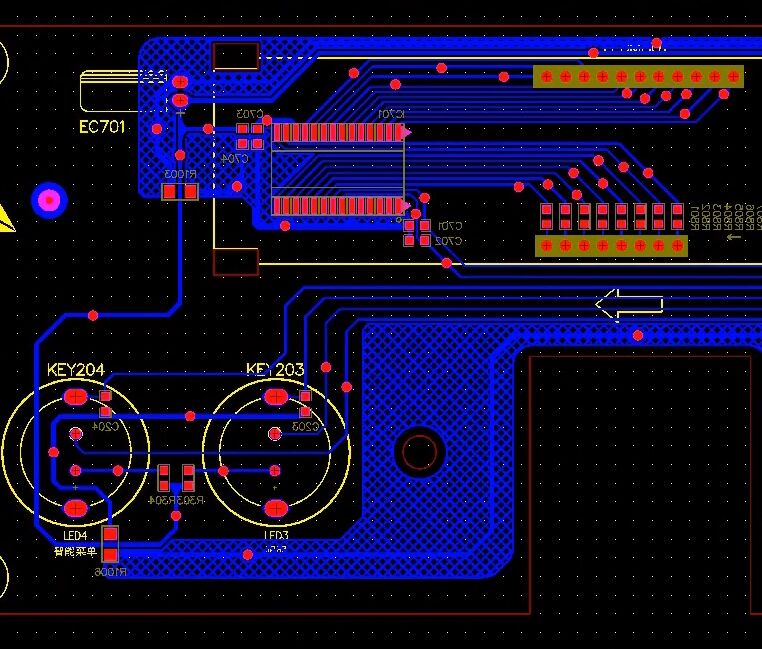

mcpcb

Metal Core Printed Circuit Boards (MCPCBs) represent a significant advancement in thermal management technology for electronic components. These specialized circuit boards feature a metal base layer, typically aluminum or copper, which serves as both a mechanical support structure and an efficient heat dissipation system. The construction consists of three primary layers: the metal core base, a thermally conductive but electrically insulating dielectric layer, and a top copper circuit layer. This unique architecture enables MCPCBs to manage heat distribution far more effectively than traditional FR4 PCBs, making them ideal for high-power applications. The metal core acts as a heat spreader, rapidly conducting thermal energy away from components and distributing it across the board's surface. This thermal management capability is particularly crucial in applications involving LED lighting, power supplies, and high-frequency circuits where heat generation can significantly impact performance and longevity. MCPCBs also offer enhanced mechanical stability due to their metal core, which helps prevent warping and provides better durability under thermal stress. The technology has become increasingly important in modern electronics, where power density and thermal management requirements continue to rise.