flexible circuit board

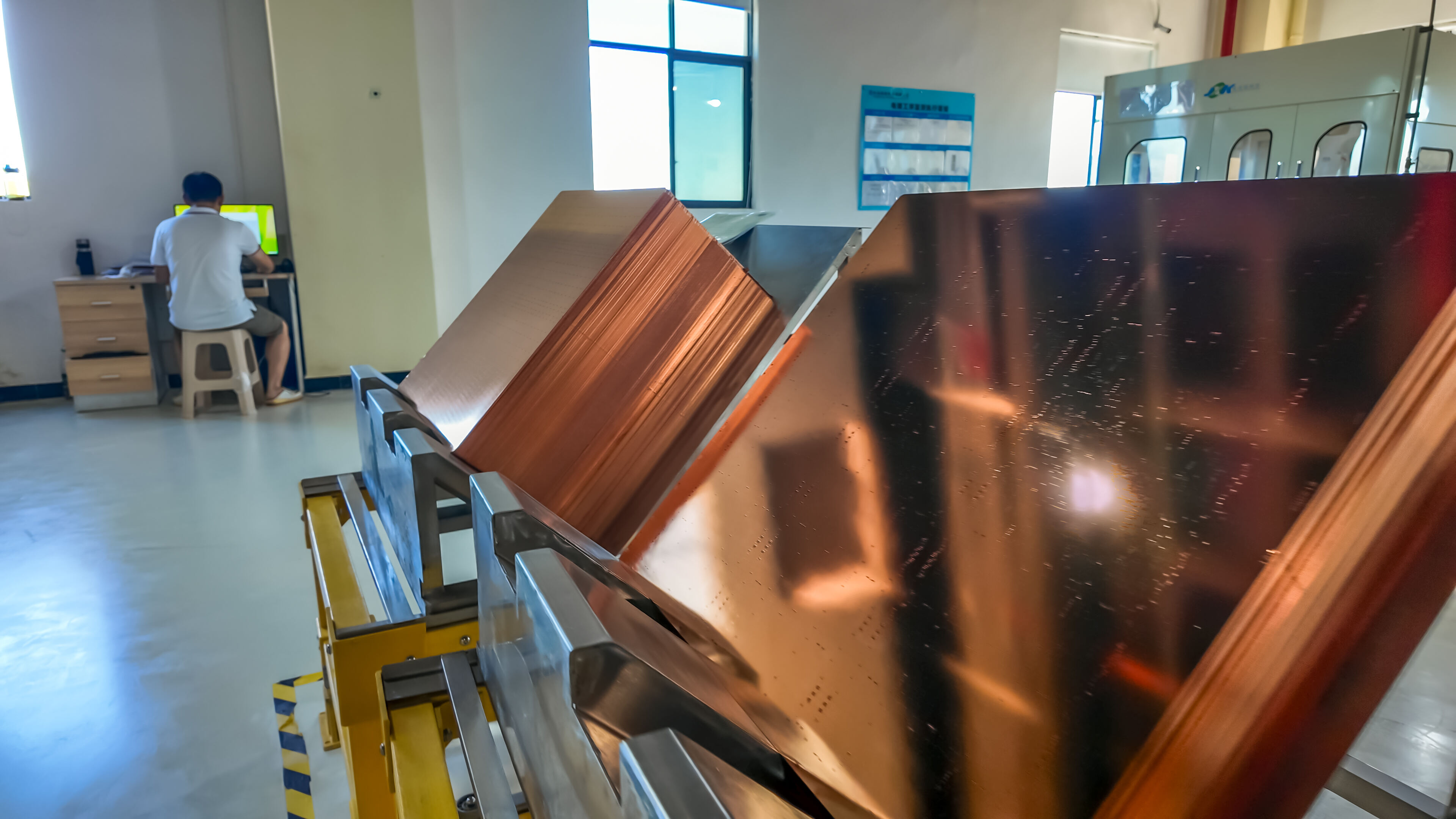

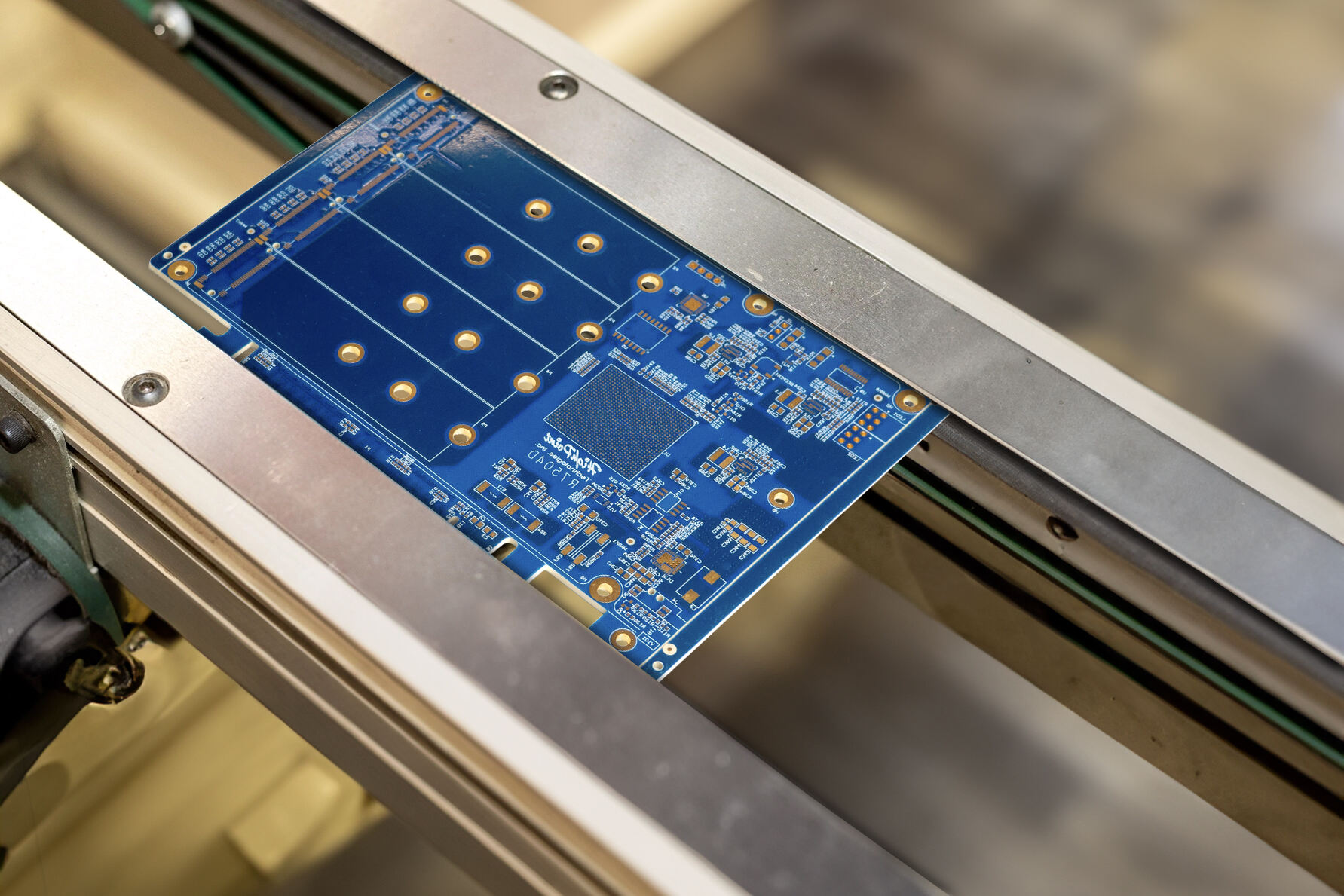

A flexible circuit board, also known as a flex PCB, represents a groundbreaking advancement in electronic design that combines electrical connectivity with mechanical flexibility. These innovative circuits are constructed on flexible polymer substrates, typically polyimide or polyester films, allowing them to bend, fold, and conform to various shapes while maintaining reliable electrical performance. The primary function of flexible circuit boards is to create interconnections between electronic components while optimizing space utilization and enabling dynamic movement. They feature conductive paths printed or etched onto the flexible substrate, which can be single-sided, double-sided, or multi-layered depending on the application requirements. The technology incorporates advanced manufacturing processes that ensure durability and reliability while maintaining the circuit's flexibility. These boards find extensive applications across multiple industries, from consumer electronics and automotive systems to medical devices and aerospace equipment. Their ability to be installed in three-dimensional configurations makes them ideal for complex electronic assemblies where traditional rigid PCBs would be impractical or impossible to implement.