what is a pcb circuit board

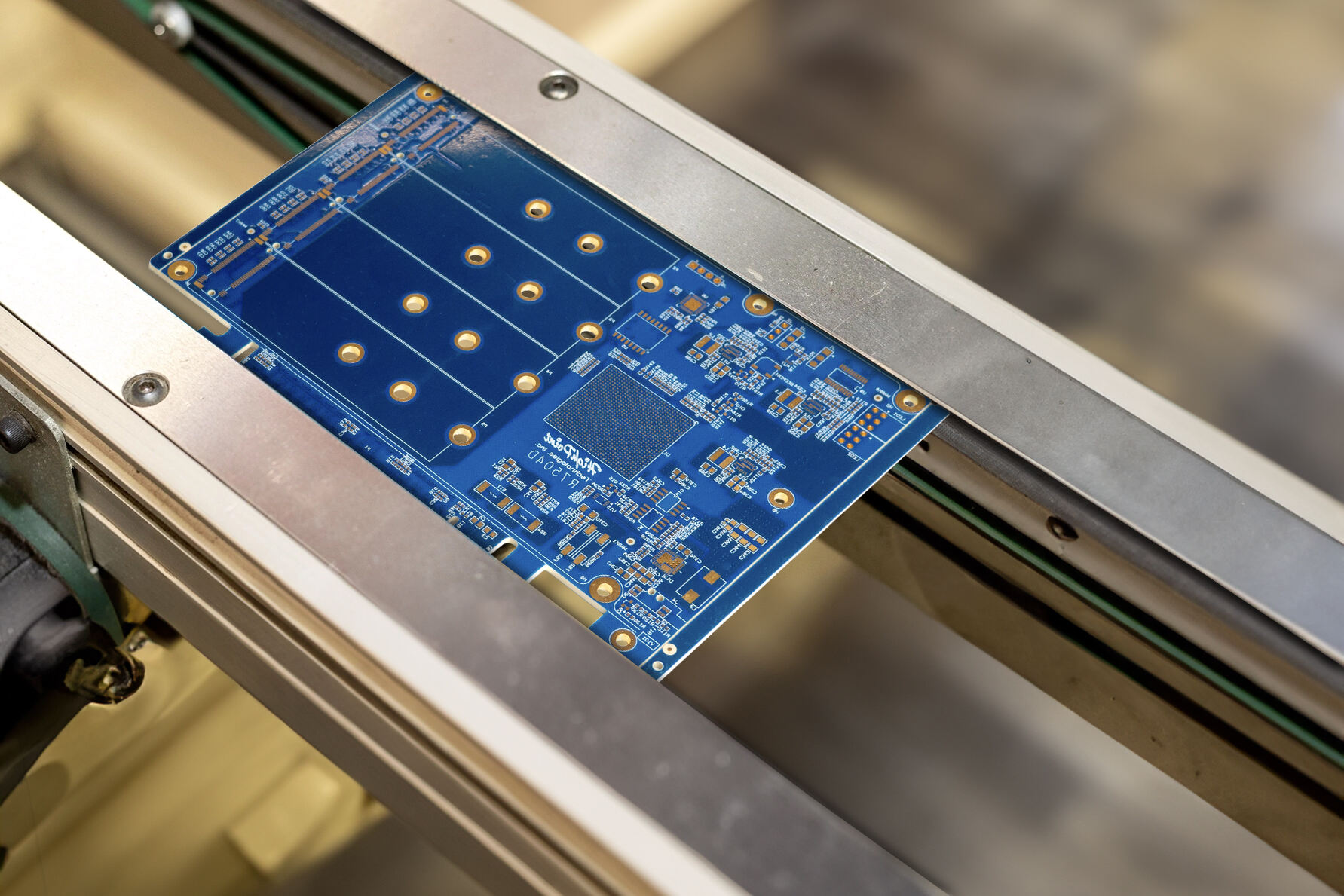

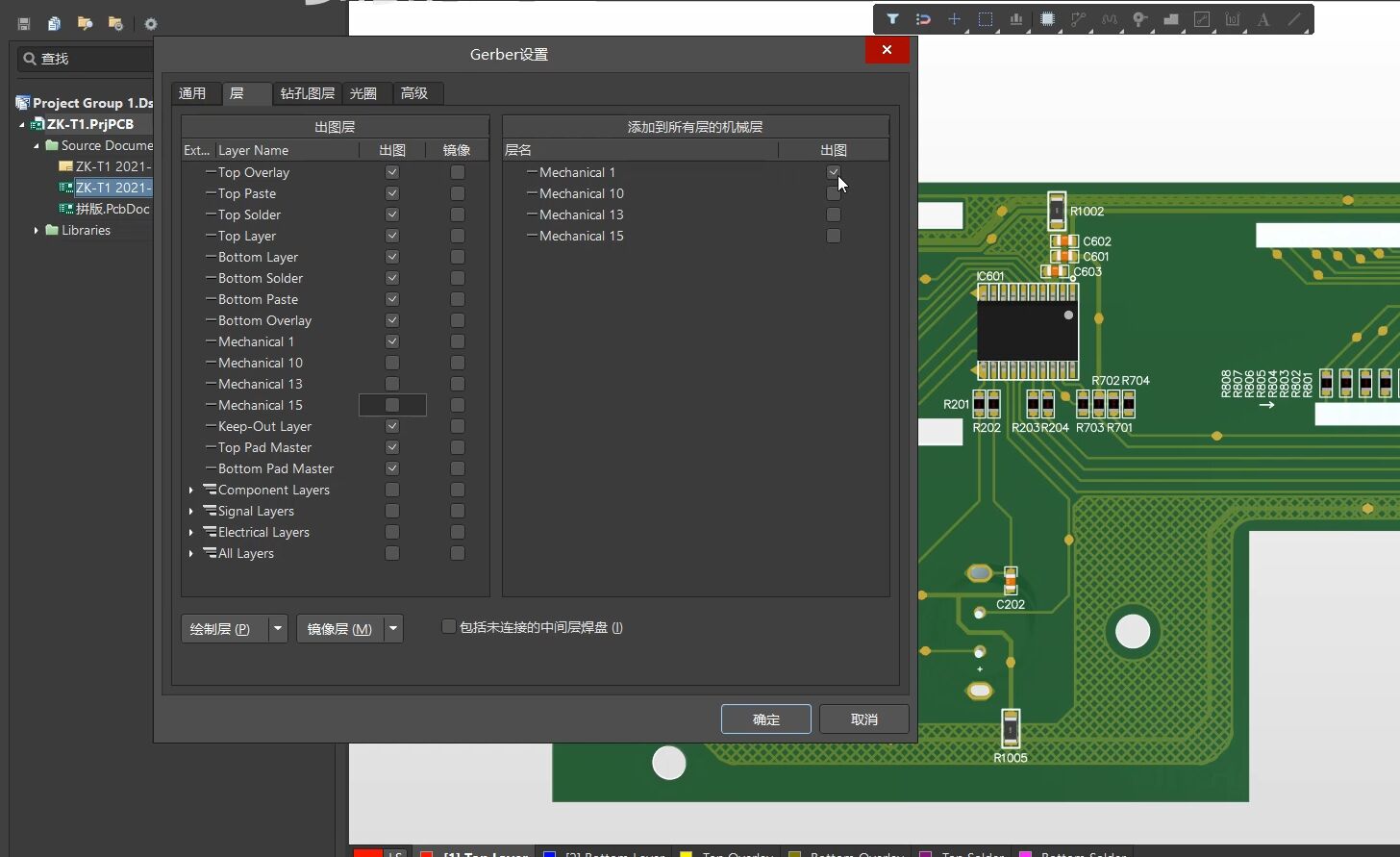

A PCB (Printed Circuit Board) is a fundamental component in modern electronics, serving as the backbone for connecting and supporting various electronic components. It consists of a non-conductive substrate material, typically made from fiberglass, with conductive pathways, known as traces, etched or printed onto its surface. These traces create the electrical connections between components like resistors, capacitors, integrated circuits, and other electronic parts. PCBs can be single-layered, double-layered, or multi-layered, depending on the complexity of the circuit design. The board's surface features mounting holes and pads where components are soldered, ensuring secure electrical and mechanical connections. Modern PCBs often incorporate advanced features such as ground planes for improved electrical performance, thermal management systems, and impedance-controlled traces for high-frequency applications. They are essential in everything from simple consumer electronics to complex industrial equipment, medical devices, and aerospace applications. The manufacturing process involves precise computer-aided design (CAD) tools, photolithography, and automated assembly techniques, ensuring consistent quality and reliability. PCBs have revolutionized electronics manufacturing by replacing traditional point-to-point wiring, making devices more compact, reliable, and cost-effective to produce at scale.