what is pcb circuit board

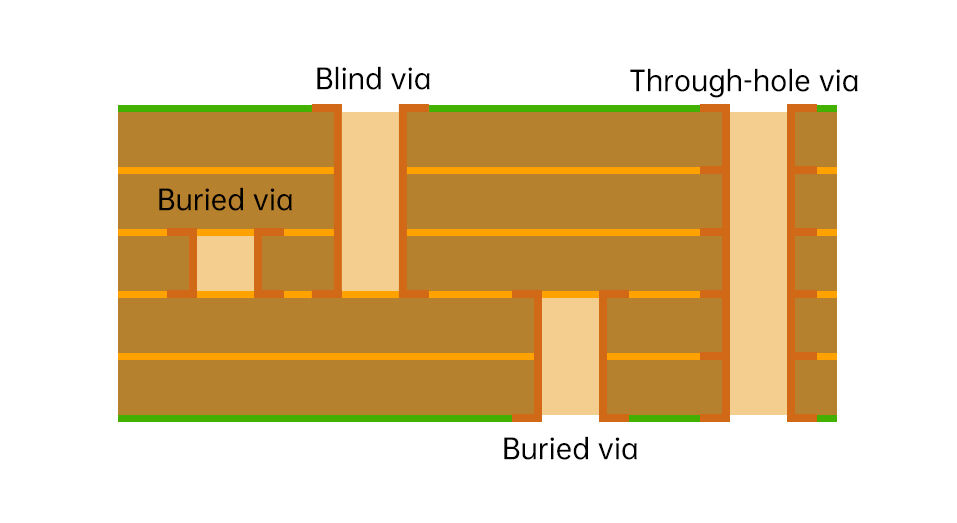

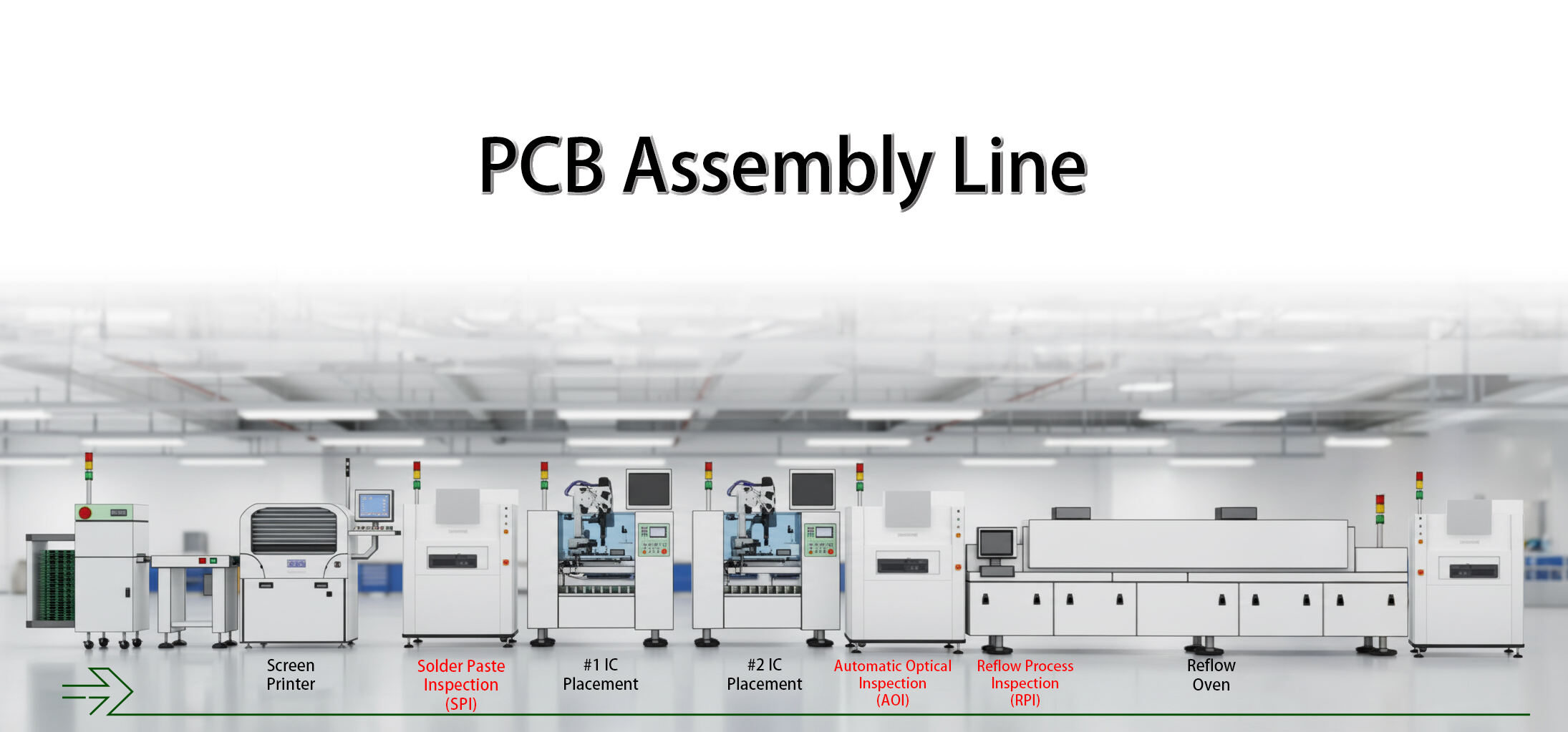

A PCB (Printed Circuit Board) is a fundamental component in modern electronics, serving as the backbone that mechanically supports and electrically connects electronic components. These boards are manufactured from layers of insulating material and copper, with the copper etched to form conductive pathways. PCBs have revolutionized electronics manufacturing by eliminating the need for bulky point-to-point wiring. The boards consist of several layers including the substrate, copper layers, solder mask, and silkscreen. Modern PCBs can be single-sided, double-sided, or multi-layered, depending on the complexity of the circuit design. They utilize through-holes and surface mount technology to attach components, enabling compact and reliable electronic devices. PCBs are essential in everything from simple consumer electronics to complex industrial equipment, medical devices, and aerospace applications. The manufacturing process involves computer-aided design (CAD) software for layout creation, followed by precise fabrication techniques including photolithography, etching, and drilling. Quality control measures ensure the boards meet strict performance and reliability standards, making them suitable for diverse applications across various industries.