aluminum pcb

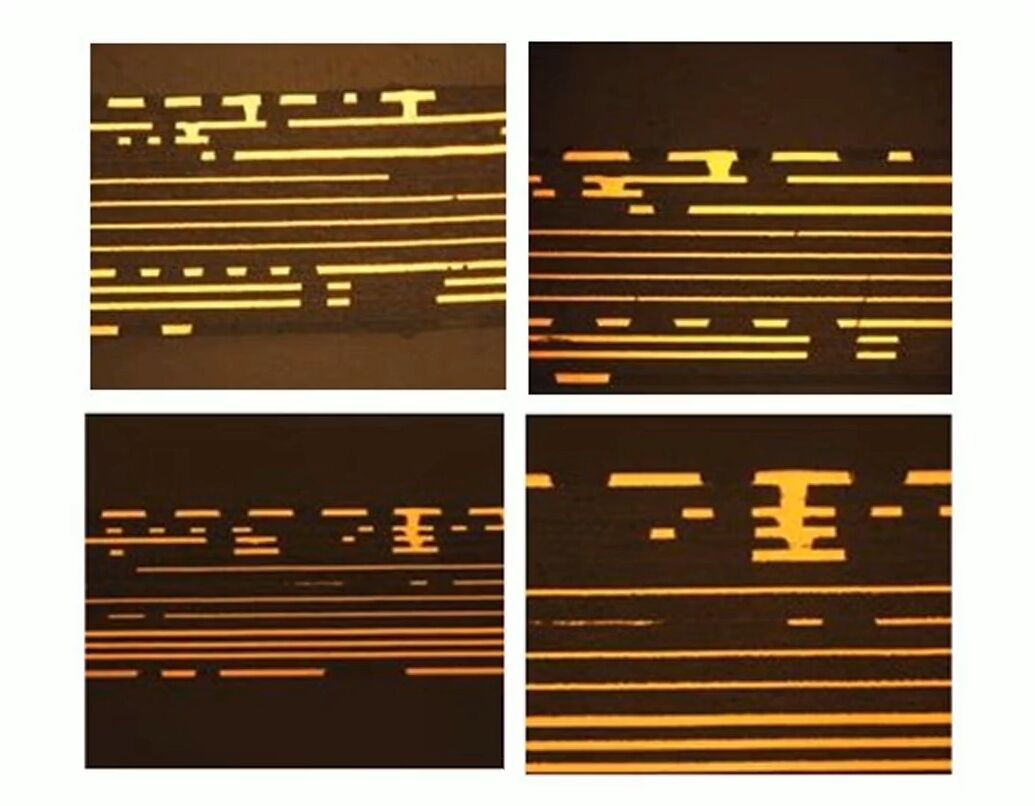

Aluminum PCB (Printed Circuit Board) represents a cutting-edge development in electronic circuit technology, featuring a metal base substrate that revolutionizes heat dissipation capabilities. These specialized circuit boards consist of a thermally conductive aluminum base layer, dielectric insulation layer, and copper circuit layer, creating a robust and efficient platform for electronic components. The aluminum base, typically ranging from 0.5mm to 3mm in thickness, serves as an excellent heat conductor, making it ideal for high-power applications. What sets aluminum PCBs apart is their superior thermal management properties, capable of dissipating heat up to 8-10 times more effectively than traditional FR4 boards. This enhanced thermal performance enables higher component density and improved reliability in demanding applications. These PCBs find extensive use in LED lighting systems, power supplies, automotive electronics, and industrial control equipment. The manufacturing process involves bonding high-grade aluminum with thermally conductive dielectric material, followed by precise circuit pattern etching and surface finishing. Advanced aluminum PCBs can withstand operating temperatures up to 150°C while maintaining structural integrity and electrical performance. Their unique construction also offers improved mechanical strength and resistance to environmental factors, making them particularly suitable for outdoor and harsh environment applications.