what is pcb circuit

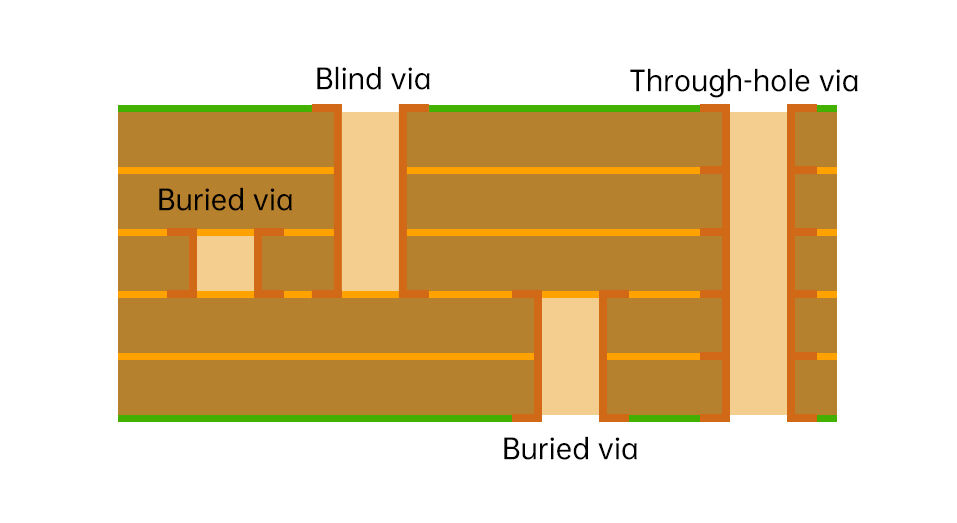

A PCB (Printed Circuit Board) circuit is a fundamental component in modern electronics, serving as the backbone for connecting electronic components through conductive pathways, pads, and features etched from copper sheets laminated onto a non-conductive substrate. These sophisticated boards consist of multiple layers that efficiently organize electrical connections while maintaining a compact form factor. PCBs provide mechanical support and electrical connections for components such as integrated circuits, resistors, capacitors, and connectors through a complex network of conductive traces. The manufacturing process involves precise techniques including photolithography, etching, and plating to create reliable electrical pathways. PCBs can range from single-layer boards used in simple electronics to complex multilayer designs found in advanced computing systems. They are essential in virtually every electronic device, from smartphones and computers to industrial equipment and medical devices. The design incorporates various elements such as power planes, ground planes, and signal traces, all carefully arranged to minimize interference and optimize performance. Modern PCB circuits often feature surface mount technology (SMT) and through-hole components, allowing for high-density component placement and efficient assembly processes.