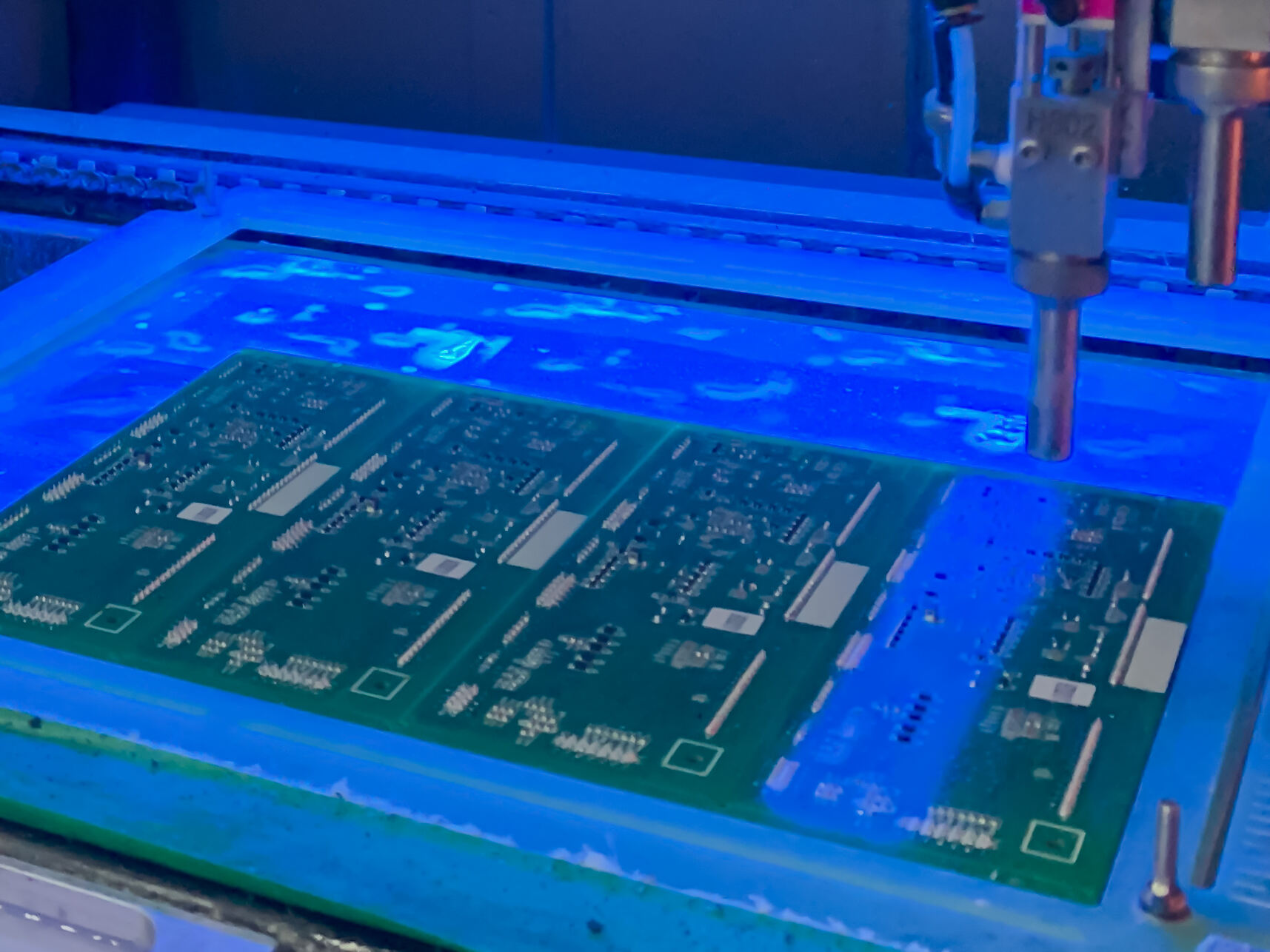

hdi pcb

High Density Interconnect (HDI) PCB technology represents a significant advancement in printed circuit board manufacturing, offering enhanced capabilities for modern electronic devices. These sophisticated boards feature higher circuitry density and significantly more complex interconnections compared to traditional PCBs. HDI PCBs utilize microvias, blind and buried vias, and advanced lamination techniques to achieve superior connectivity in a compact form factor. The technology enables the creation of boards with finer lines and spaces, smaller vias, and higher connection pad density, making it possible to accommodate more components in a smaller area. HDI PCBs typically incorporate multiple layers, often ranging from 4 to 12 or more, interconnected through sophisticated via structures. The manufacturing process involves advanced techniques such as laser drilling, sequential lamination, and precise registration methods. These boards are particularly crucial in modern electronics where miniaturization and high performance are essential requirements. They find extensive applications in smartphones, tablets, wearable devices, medical equipment, aerospace technology, and other high-end electronic products where space optimization and signal integrity are paramount considerations.