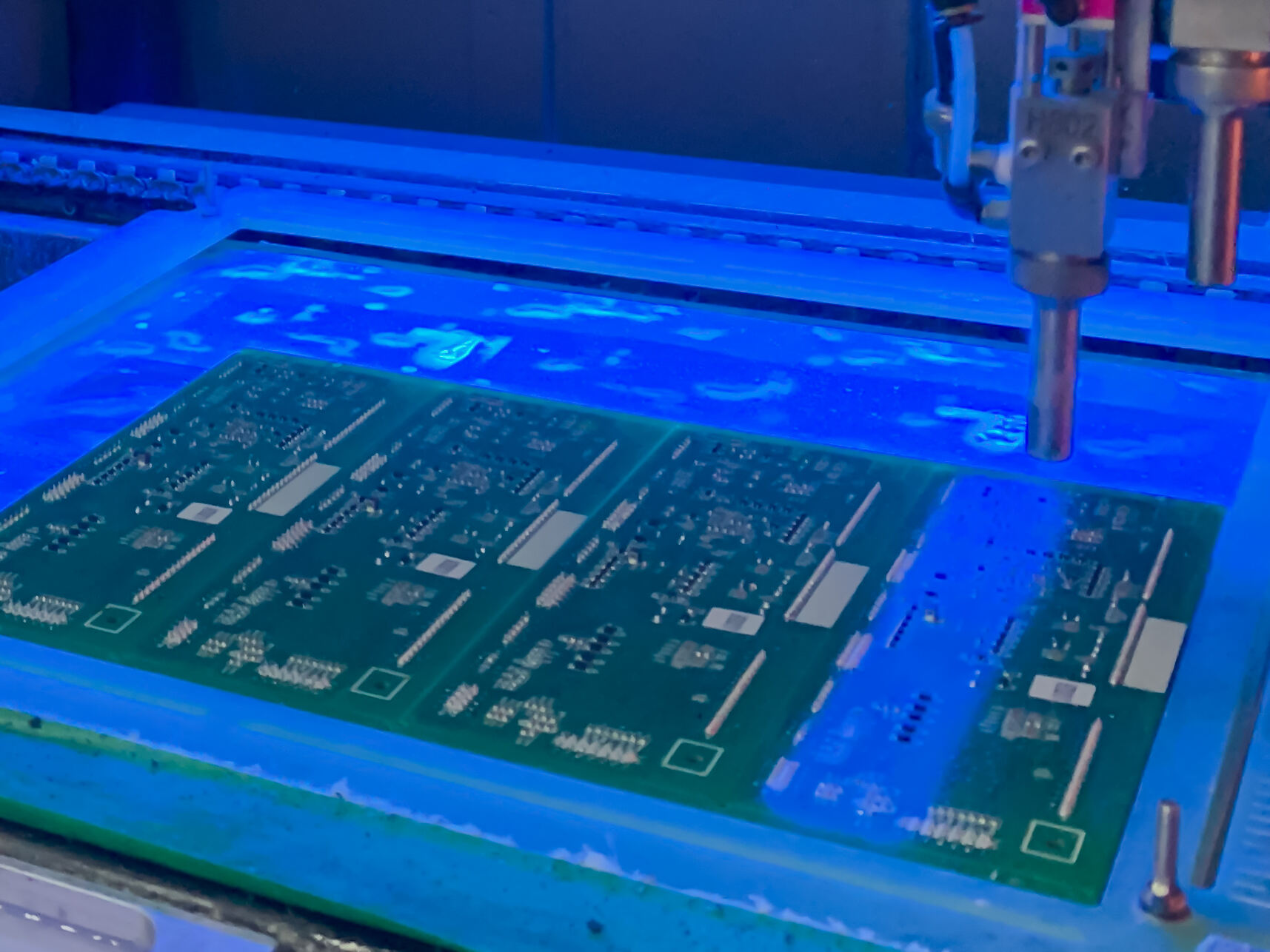

led pcb

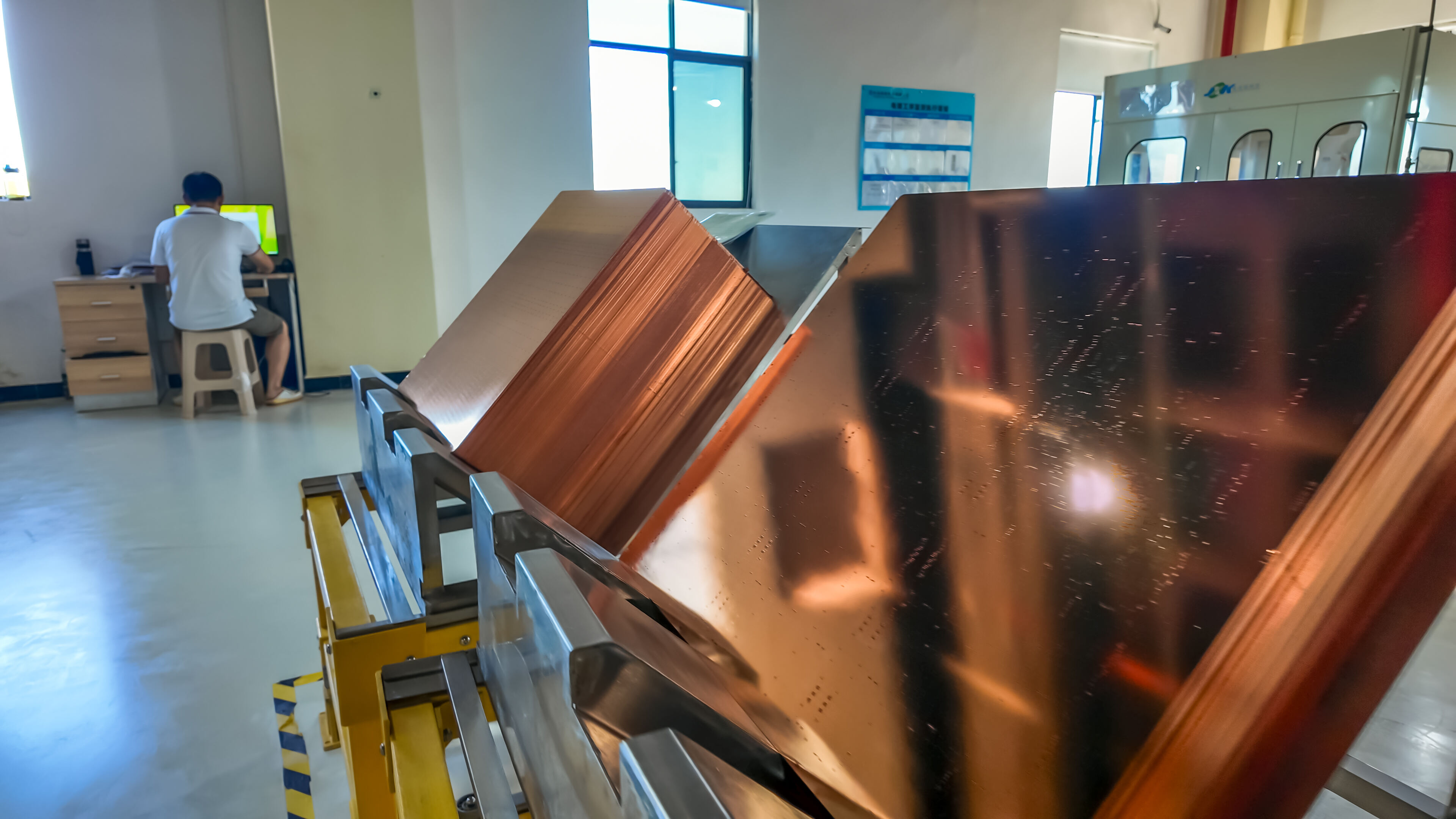

LED PCB (Printed Circuit Board) represents a crucial advancement in modern lighting technology, serving as the foundational platform for LED lighting systems. These specialized circuit boards are engineered to provide optimal thermal management, electrical conductivity, and mechanical support for LED components. The primary function of LED PCBs is to efficiently distribute power to the LED chips while simultaneously managing heat dissipation, which is critical for maintaining LED longevity and performance. These boards typically feature a multi-layer construction, with the base layer often composed of aluminum or other thermally conductive materials. The design incorporates sophisticated copper traces that create electrical pathways, connecting various components such as resistors, capacitors, and LED chips. Modern LED PCBs utilize advanced surface mount technology (SMT) for component placement, enabling compact designs and improved manufacturing efficiency. These boards find extensive applications across various sectors, including automotive lighting, commercial illumination, residential fixtures, and industrial lighting solutions. The versatility of LED PCBs allows for customization in terms of size, shape, and configuration, making them suitable for diverse lighting requirements.