what are pcb used for

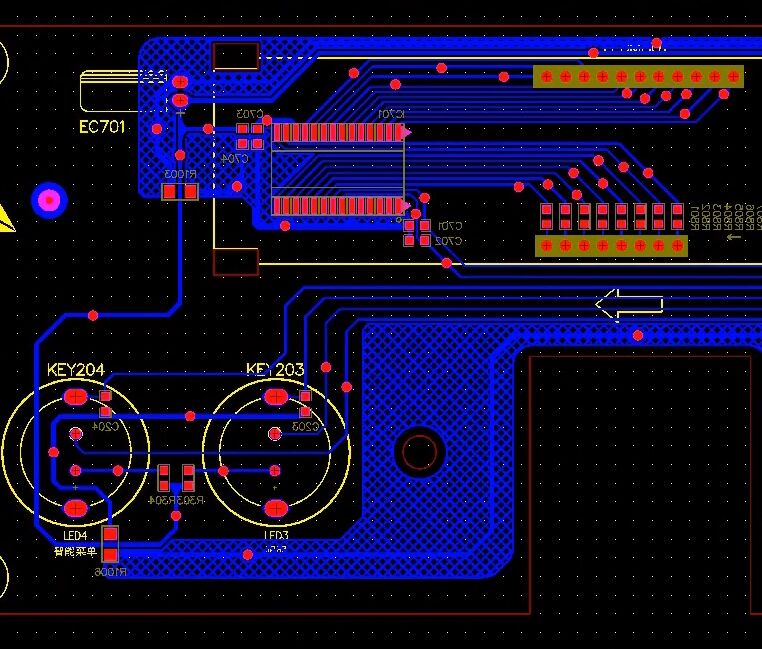

Printed Circuit Boards (PCBs) are fundamental components in modern electronics, serving as the backbone for connecting electronic components in a structured and efficient manner. These specialized boards consist of conductive pathways, or traces, etched from copper sheets and laminated onto a non-conductive substrate. PCBs are used in virtually every electronic device, from simple calculators to complex aerospace systems. They provide mechanical support for electronic components while establishing electrical connections between them through conductive paths. The primary function of PCBs is to create a reliable and organized platform for electronic circuits, enabling consistent production of electronic devices at scale. Modern PCBs can be manufactured in multiple layers, allowing for more complex circuits in smaller spaces, and can incorporate advanced features such as impedance control, thermal management, and electromagnetic shielding. They are extensively used in consumer electronics, industrial equipment, medical devices, automotive systems, telecommunications infrastructure, and military applications. The versatility of PCBs allows them to be customized for specific applications, with various materials and design specifications available to meet different performance requirements, environmental conditions, and reliability standards.