what is pcb manufacturing

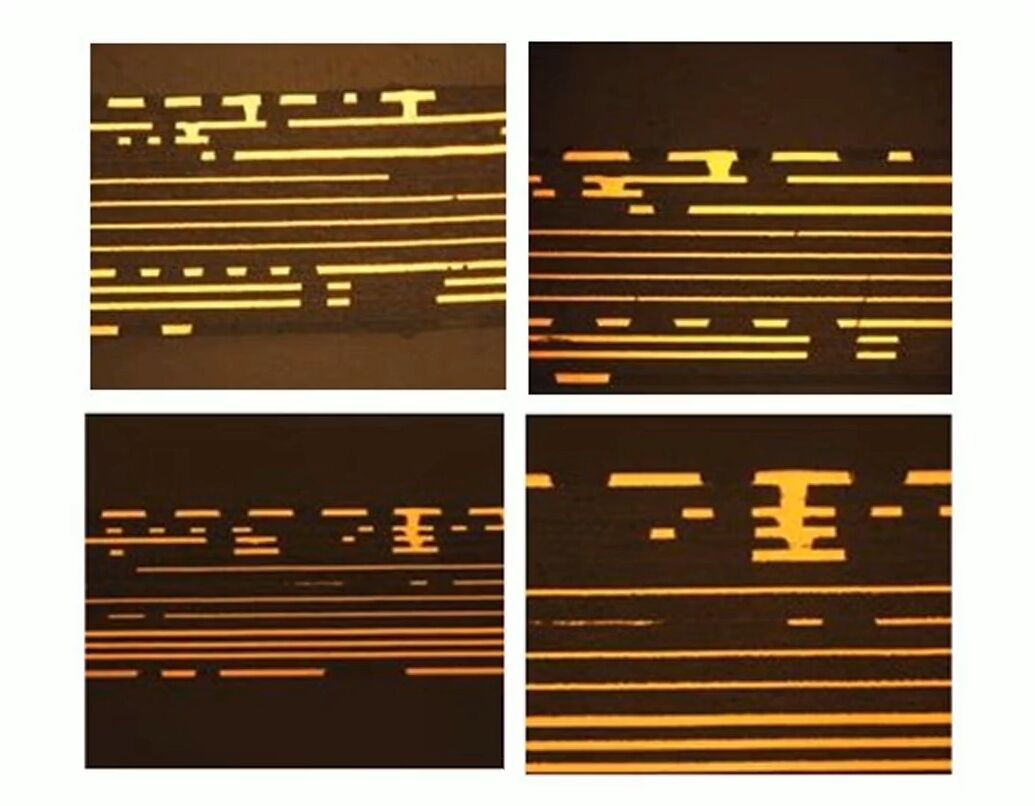

PCB manufacturing is a sophisticated process that involves creating printed circuit boards, which are essential components in modern electronic devices. This process encompasses multiple stages, from initial design to final assembly, utilizing advanced technology and precision engineering. The manufacturing begins with a substrate material, typically made of fiberglass, upon which copper layers are bonded. These layers are then precisely etched to create intricate circuit patterns that will connect various electronic components. The process includes photolithography, where the circuit design is transferred onto the board, followed by chemical etching to remove unwanted copper, leaving only the desired circuit paths. Advanced PCB manufacturing also incorporates through-hole technology and surface mount technology, allowing for complex multi-layer boards that can accommodate high-density component placement. Quality control measures are implemented throughout the process, including automated optical inspection and electrical testing, ensuring each board meets strict performance standards. Modern PCB manufacturing facilities employ state-of-the-art equipment and clean room environments to maintain the highest quality standards and minimize defects.