high tg pcb

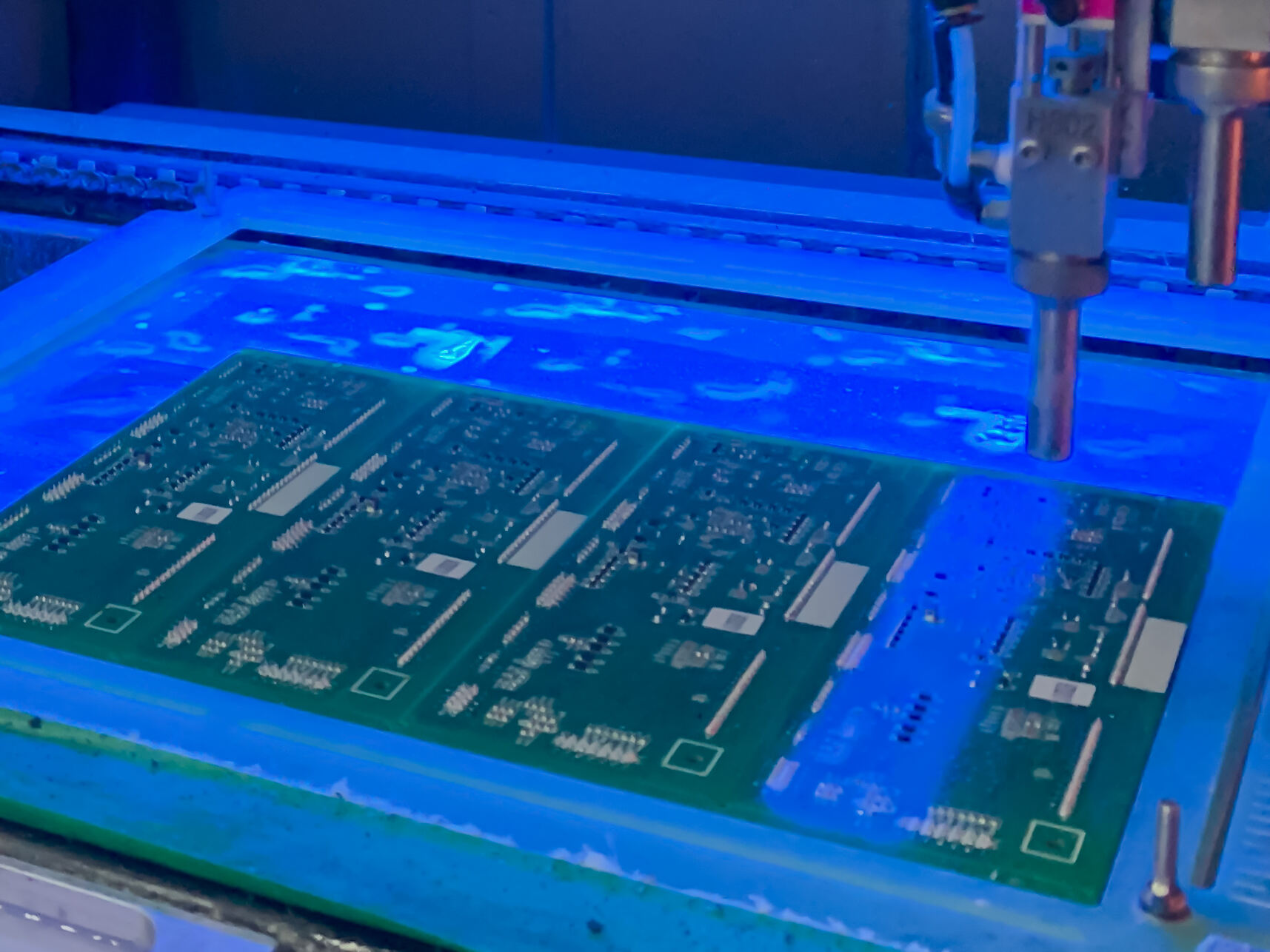

High Tg PCB (Printed Circuit Board) represents a significant advancement in electronic manufacturing, specifically designed to withstand elevated temperatures and challenging operating conditions. The term Tg refers to the glass transition temperature, indicating the point at which the board material transitions from a rigid to a more flexible state. These specialized PCBs typically feature glass transition temperatures ranging from 170°C to 180°C or higher, making them ideal for high-performance applications. The construction involves advanced materials, usually incorporating modified epoxy resins and reinforced substrates, which maintain their structural integrity and electrical properties even under extreme thermal stress. High Tg PCBs excel in applications requiring exceptional thermal stability, such as automotive electronics, aerospace systems, and high-power industrial equipment. They demonstrate superior resistance to delamination, improved dimensional stability, and enhanced reliability in demanding environments. The manufacturing process employs precise temperature control and specialized lamination techniques to ensure consistent quality and performance. These boards also offer excellent electrical properties, including low signal loss and improved impedance control, making them essential for high-frequency applications and complex electronic systems.