fr4 printed circuit board

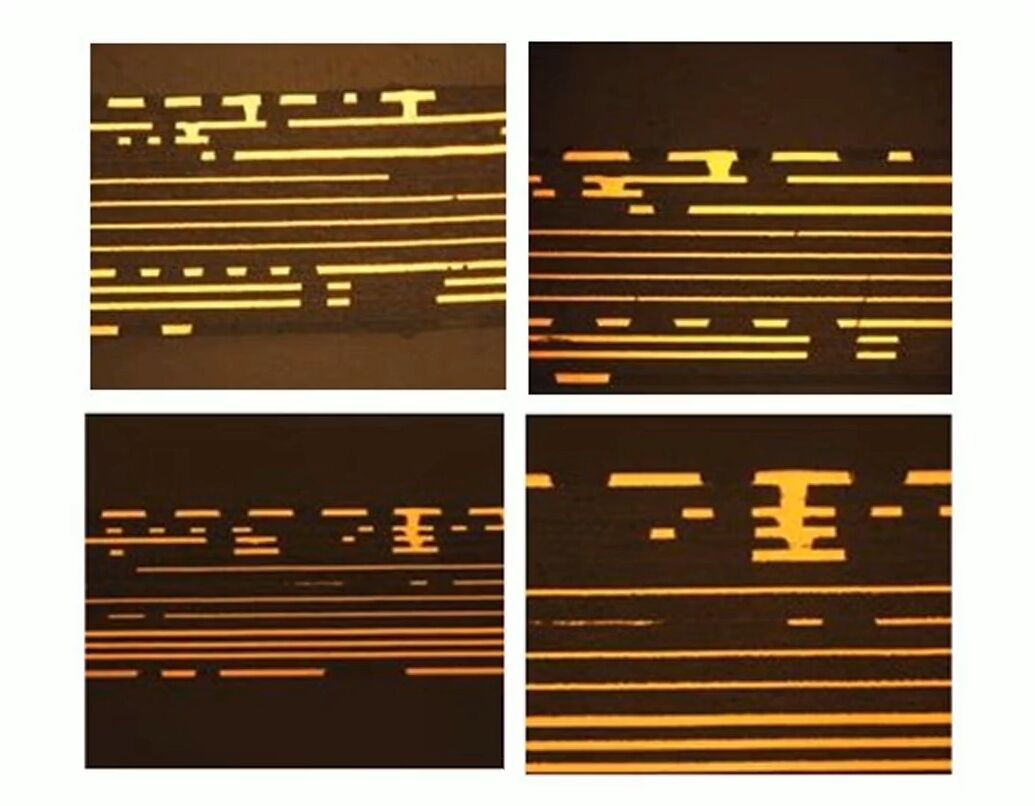

FR4 printed circuit boards represent the backbone of modern electronics manufacturing, serving as the foundation for countless electronic devices and systems. These versatile boards consist of multiple layers of fiberglass reinforced epoxy laminate material, providing exceptional mechanical strength and electrical insulation properties. The FR4 designation indicates flame retardant properties, meeting UL94 V-0 standards for safety and reliability. These PCBs feature copper traces that create intricate pathways for electrical signals, allowing components to communicate and function effectively. The manufacturing process involves precise layering of copper and FR4 material, followed by chemical etching to create circuit patterns. FR4 PCBs offer outstanding thermal stability, maintaining their structural integrity across a wide temperature range from -50°C to +140°C. Their low moisture absorption rate, typically less than 0.1%, ensures consistent electrical performance in varying environmental conditions. The material's high dielectric strength, approximately 20kV/mm, provides excellent electrical insulation, making it suitable for both low and high-voltage applications. These boards can be manufactured in various thicknesses, typically ranging from 0.4mm to 3.2mm, accommodating different design requirements and applications.