tg pcb

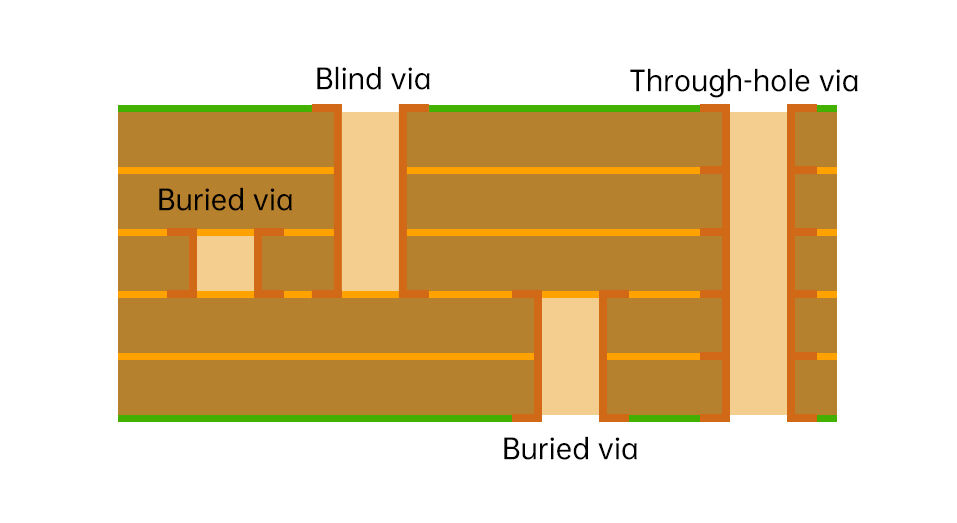

TG PCB, or Tg (Glass Transition Temperature) Printed Circuit Board, represents a significant advancement in electronic circuit board manufacturing. This specialized PCB is engineered with materials that exhibit specific glass transition temperatures, determining their thermal stability and performance characteristics. The TG rating indicates the temperature at which the material begins to transition from a rigid state to a more flexible one, crucial for maintaining structural integrity in various operating conditions. These PCBs are manufactured using high-quality epoxy resins and reinforcement materials, offering exceptional thermal resistance and mechanical stability. TG PCBs are available in different temperature ranges, typically from 130°C to 180°C, making them suitable for diverse applications across industries. The boards feature multiple layers of copper traces, interconnected through precise via holes and protected by solder mask and silkscreen layers. Their robust construction ensures reliable performance in demanding environments, while their advanced material composition provides enhanced signal integrity and reduced signal loss. These characteristics make TG PCBs particularly valuable in high-performance electronics, telecommunications equipment, and industrial control systems where thermal management and reliability are paramount.