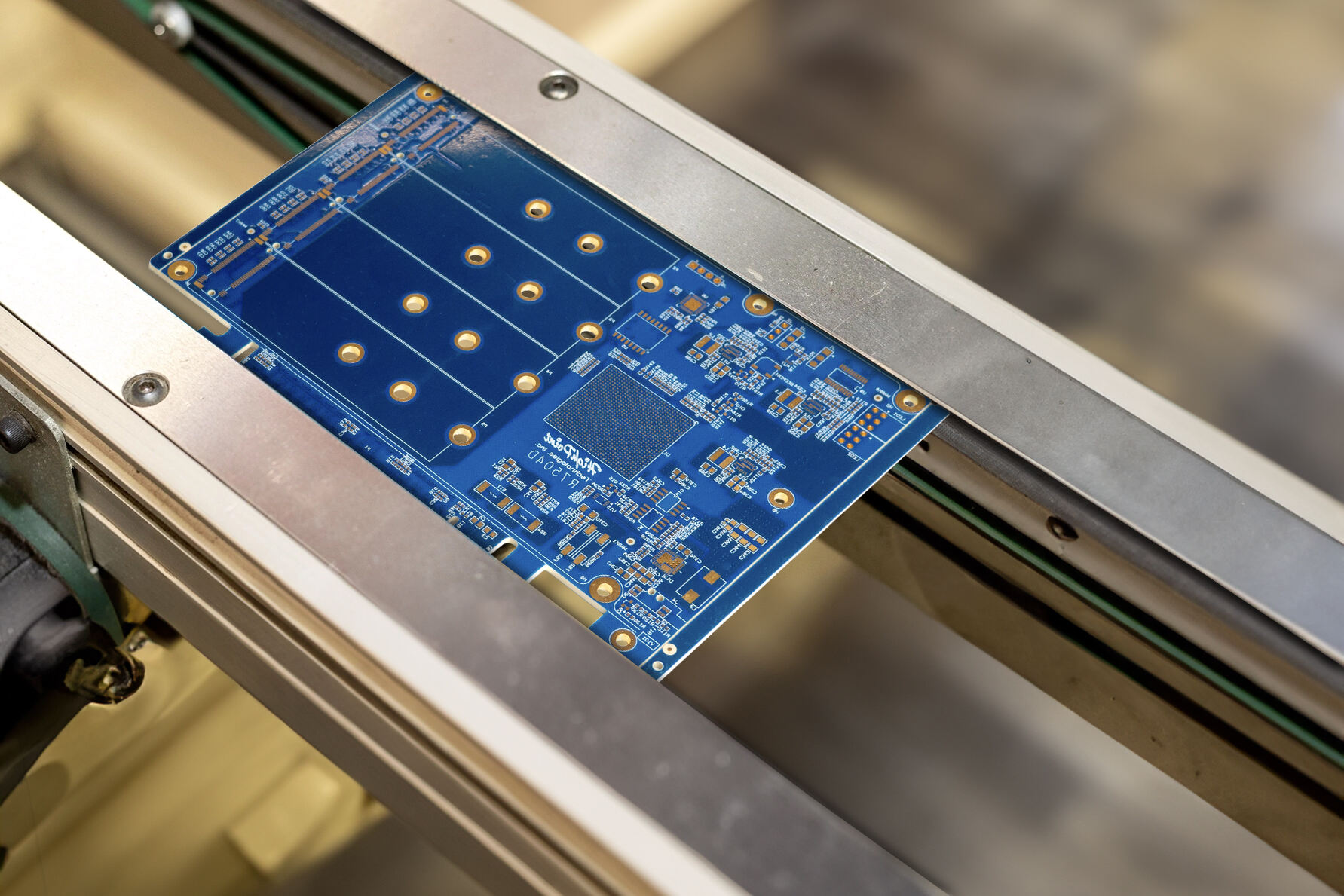

copper based pcb

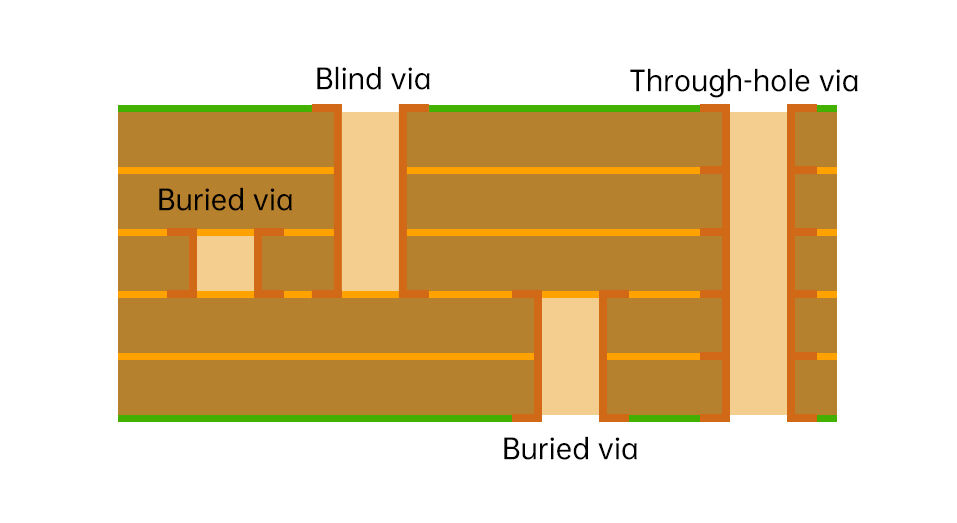

Copper based PCB (Printed Circuit Board) represents a fundamental component in modern electronics manufacturing, featuring a substrate material layered with copper foil. This essential electronic component serves as the backbone for connecting various electronic components through conductive pathways etched onto copper layers. The base material typically consists of FR-4 glass-epoxy, providing excellent mechanical strength and electrical insulation properties. The copper layer, ranging from 0.5 to 3 ounces per square foot, creates reliable electrical connections between components. These PCBs can be manufactured in single-layer, double-layer, or multi-layer configurations, offering versatility for different applications. The manufacturing process involves precise copper etching, where unwanted copper is removed to create specific circuit patterns. Modern copper based PCBs incorporate advanced features such as impedance control, thermal management capabilities, and high-frequency signal handling. They find widespread use in consumer electronics, automotive systems, telecommunications equipment, and industrial control systems. The reliability and conductivity of copper make these PCBs ideal for both low-power applications and high-performance computing devices, ensuring consistent electrical performance and heat dissipation.